Supercritical water coal gasification device and method

A technology of supercritical water and coal gasification, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gases, and the production of bulk chemicals. Difficult to realize and other problems, to achieve the effect of avoiding the air separation process, avoiding the reaction rate, and saving air separation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

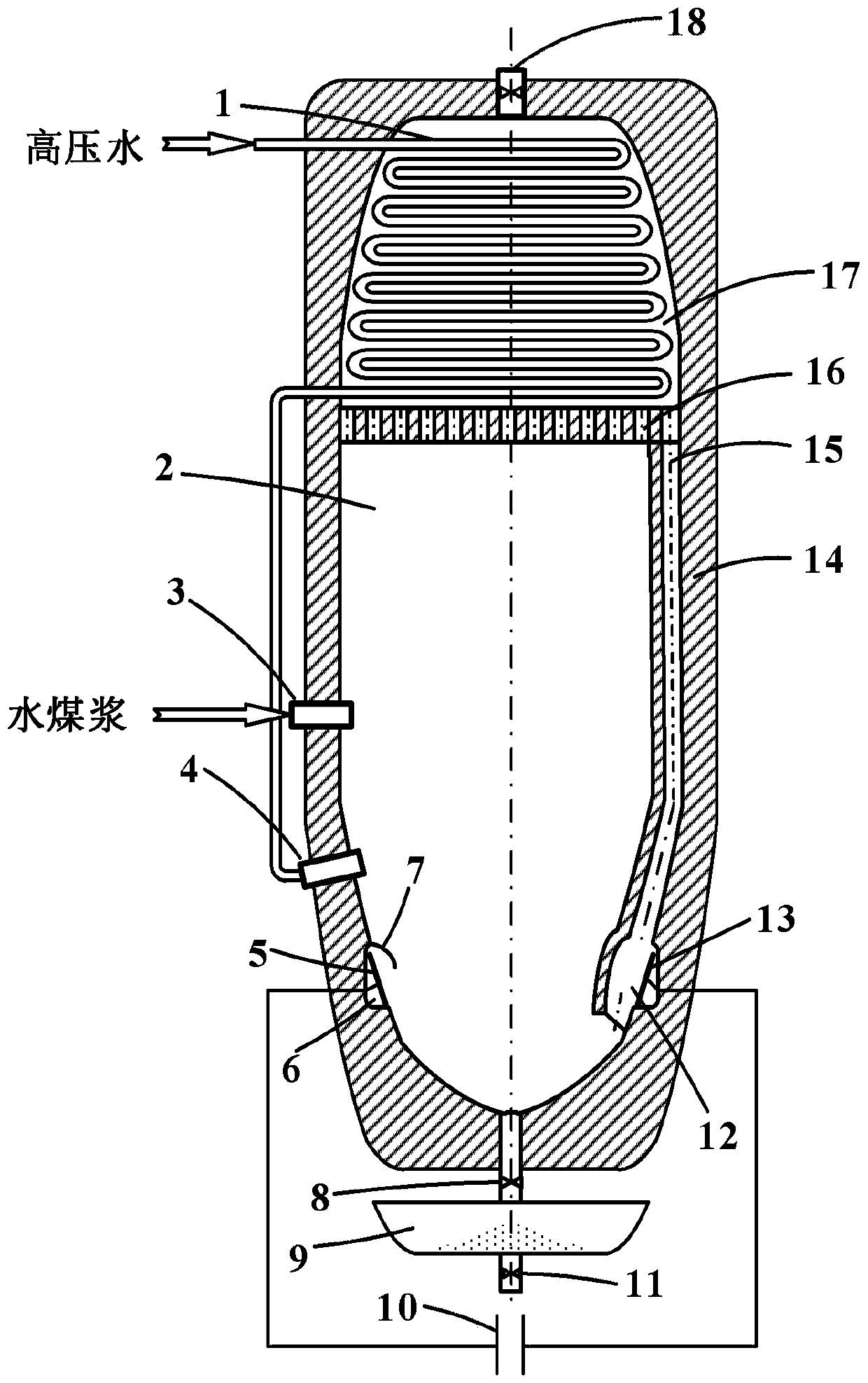

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0027] The invention discloses a supercritical water-coal gasification device and method for complementary utilization of coal and electricity, which are suitable for high-efficiency and clean utilization of inferior coal. Specifically, the supercritical water coal gasification device of the present invention includes:

[0028] The water electrolysis unit is located in the middle and lower part of the supercritical water-coal gasification device, and is used to electrolyze water into hydrogen and oxygen, and the hydrogen generated by electrolysis is directly passed to the top of the supercritical water-coal gasification device and the gasification reactor through a conduit The discharged gasification products are mixed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com