Supercritical water gasification and supercritical carbon dioxide Brayton cycle joint production system

A supercritical water gasification and Brayton cycle technology, applied in the production of bulk chemicals, granular/powdered fuel gasification, machines/engines, etc. The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

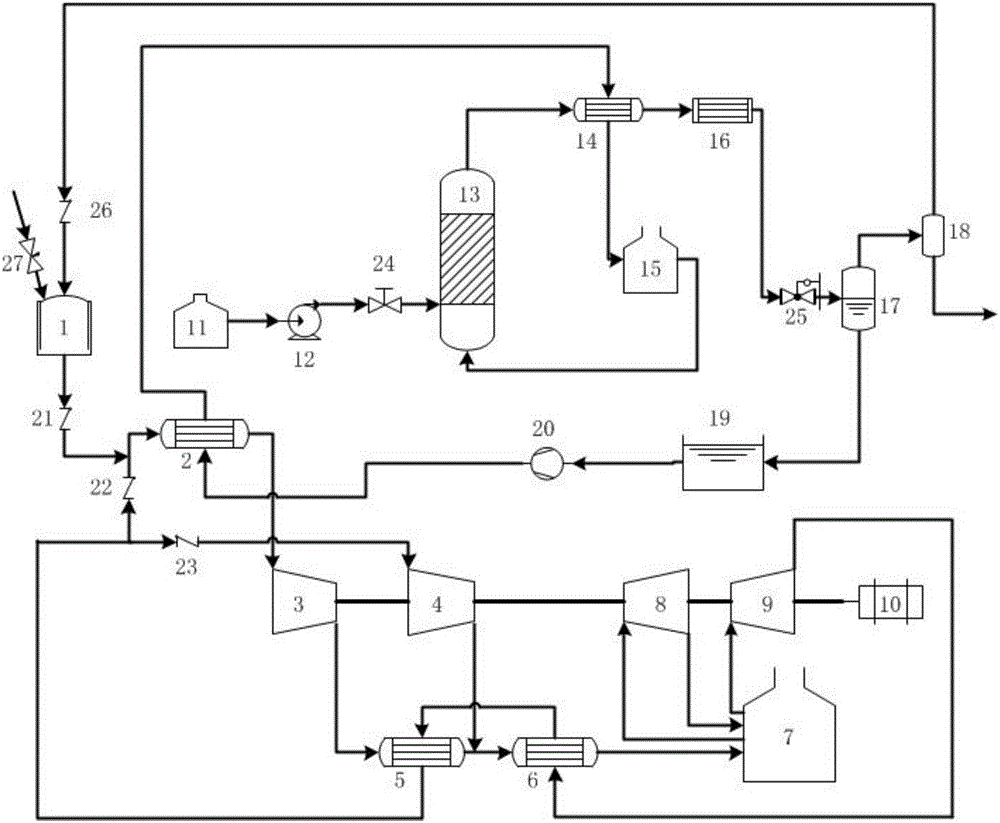

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] refer to figure 1 The supercritical water gasification and supercritical carbon dioxide Brayton cycle combined production system described in the present invention includes a supercritical carbon dioxide Brayton cycle power generation system and a supercritical water gasification coal, biomass or organic waste reaction system; the supercritical The critical water gasification coal, biomass or organic waste reaction system includes a stocker 11, a supercritical water gasification reactor 13, a regenerator 14, a cooler 16, a first heat source 15, a water tank 19, and a gas-liquid separator 17. Gas separation device 18, carbon dioxide storage tank 1 and waste heat recovery device 2; the outlet of the stocker 11 is connected with the feed port of the supercritical water gasification reactor 13, and the outlet of the supercritical water gasification reactor 13 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com