Modified gypsum-based self-leveling mortar and preparation and application thereof

A self-leveling mortar, gypsum-based technology, applied in the field of mortar, can solve problems such as poor water resistance, and achieve the effects of improving fluidity and stability, and improving construction and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of building gypsum in Examples 1-4 is as follows: phosphogypsum is pre-mixed with desulfurized gypsum in a mass ratio of 1:1 after appropriate pretreatment to neutrality (pH ≈ 7), and the tail steam generated by power generation of the power plant mixes the gypsum at 75%. After drying at °C, calcined at 150 °C for 2 hours; then ground to 200 mesh; aged for 7 days after cooling.

[0073] The manufacturing method and testing method of the test pieces in the examples were carried out in accordance with the relevant regulations of the building materials industry standard JC / T1023-2007 gypsum-based self-leveling mortar. The softening coefficient is the ratio of the compressive strength after immersion in water for 48 hours to the absolute dry compressive strength before immersion in water.

Embodiment 1

[0075] The sand ratio R of the modified gypsum-based self-leveling mortar medium-grade sand is 40%, and the water-cement ratio is 0.38;

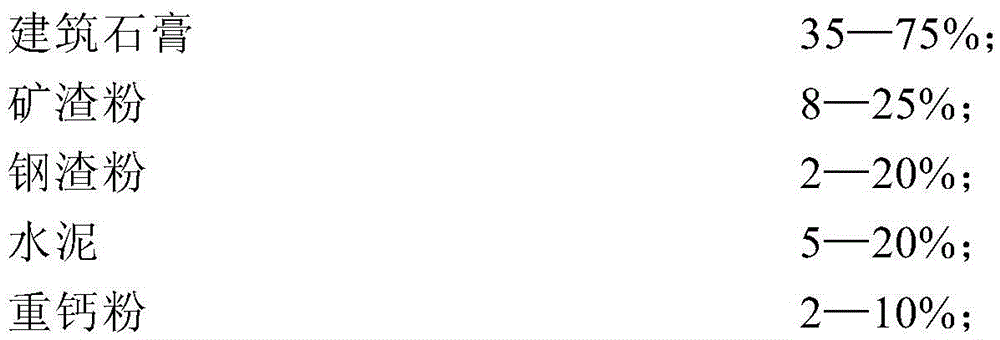

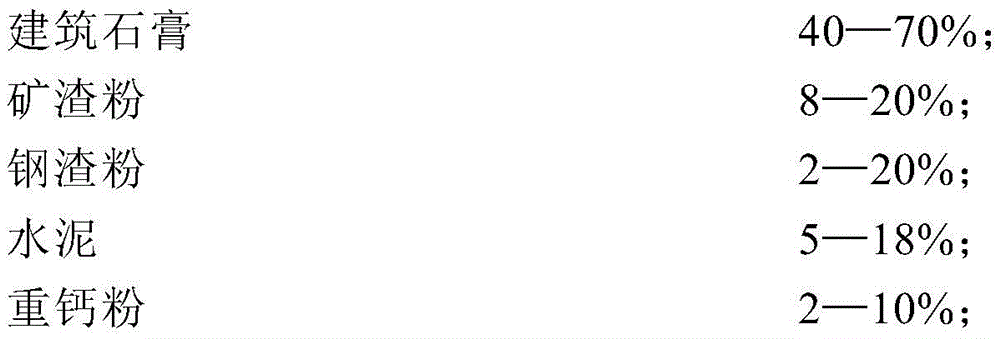

[0076] The main components of modified gypsum are: building gypsum 65%, slag powder 20%, steel slag powder 2%, cement 8%, heavy calcium powder 5%;

[0077] Building admixtures and their percentage per thousand to the quality of the main materials are: retarder 2‰, water reducing agent 2‰, defoamer 0.3‰, cellulose ether 0.5‰, redispersible latex powder 5‰;

[0078] The performance is as follows:

[0079]

Embodiment 2

[0081] The sand ratio R of the modified gypsum-based self-leveling mortar medium-grade sand is 40%, and the water-cement ratio is 0.36;

[0082] The main components of modified gypsum are: building gypsum 45%, slag powder 12%, steel slag powder 20%, cement 18%, heavy calcium powder 5%;

[0083] The building admixtures and their percentage per thousand to the quality of the main materials are: retarder 1.7‰, water reducing agent 4‰, defoamer 2‰, cellulose ether 2‰, redispersible latex powder 15‰;

[0084] The performance is as follows:

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com