Method and device for preparing active carbon and byproducts of combustion gas and tar through conversion of coal in supercritical water

A technology for preparing activated carbon and supercritical water, which is applied in the field of coal chemical industry and can solve problems such as poor economy, low conversion rate, and insufficient reuse of hot steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

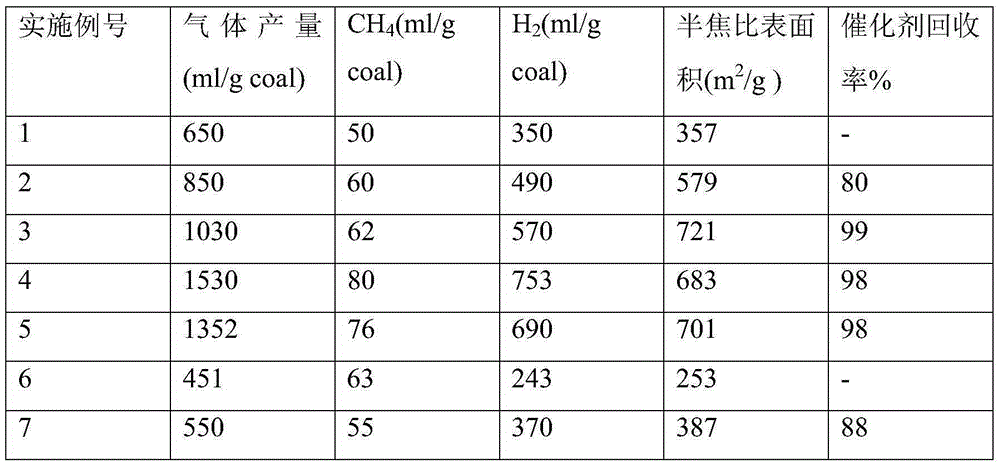

Examples

Embodiment 1

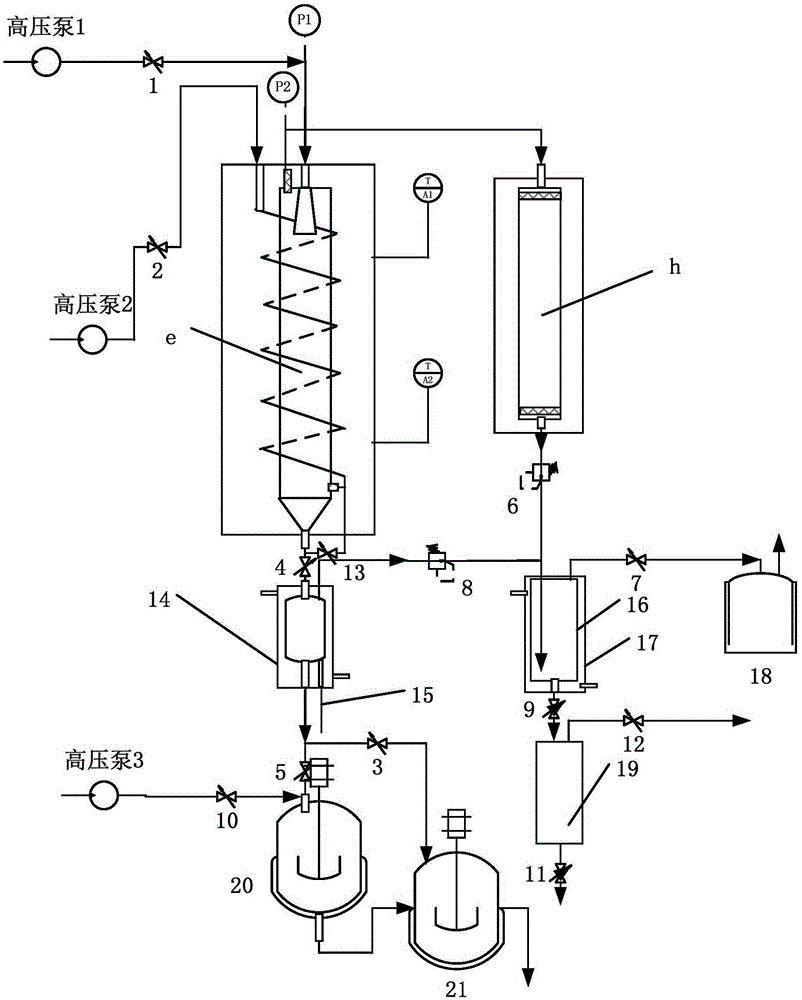

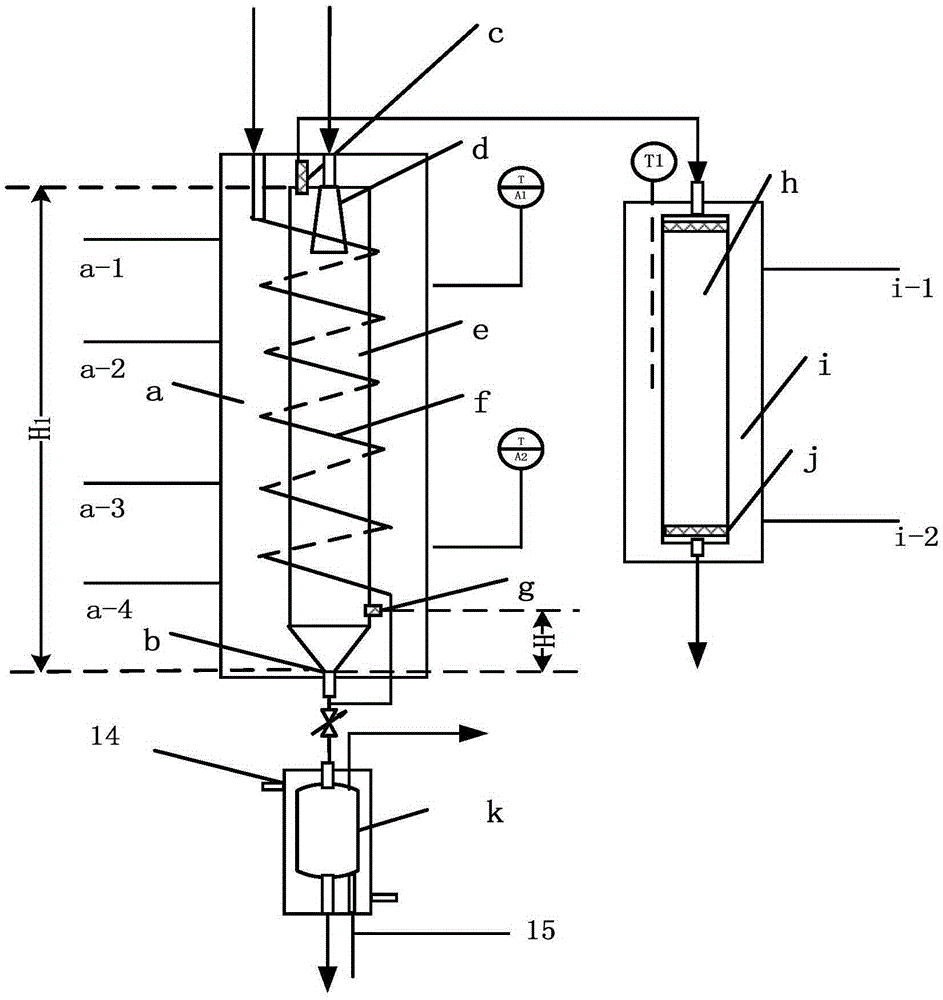

[0059] The reactor of the present invention includes a supercritical water reactor e, a catalytic reactor h, a coal slurry preheater d, a water preheater f, a solid collection tank k, and a supercritical water reactor outlet at the top of the supercritical water reactor e c, there is a coal slurry preheater d in the upper part of the supercritical water reactor e, the bottom of the supercritical water reactor e has a conical outlet b, and the lower part of the supercritical water reactor e has a supercritical water reactor water inlet g , the outer wall of the supercritical water reactor e is surrounded by a water preheater f, and there are two outlets at the bottom of the water preheater f, one outlet is connected to the water inlet g of the supercritical water reactor, and the other outlet is connected to the conical outlet b2 Both are connected to the solid collection tank k through the high-pressure ball valve 4, the electric furnace a heated by the supercritical water reac...

Embodiment 2

[0074] The supercritical water reactor e is a vertical reactor, the main body is cylindrical, the inner diameter of the cylinder is 50mm, and the bottom is a tapered outlet b, which is beneficial to the smooth discharge of solid products.

[0075] The supercritical water heating electric furnace a is controlled by three stages of control points a-1, a-2 and a-3, which can realize uniform and adjustable temperature. The coal slurry preheater d is a trumpet-shaped tube with a thin upper part and a thicker lower part. The inner diameter is 20mm at the thickest part. The water inlet g of the supercritical water reactor has a filter membrane, and the outlet c of the supercritical water reactor has a filter membrane with a pore size of 10 μm.

[0076] The outlet c of the supercritical water reactor at the top of the supercritical water reactor e is provided with a filter membrane, and the filter membrane aperture is 10 μm to prevent solid materials from being taken out of the reactor...

Embodiment 3

[0084] The supercritical water reactor e is a vertical reactor, the main body is cylindrical, the inner diameter of the cylinder is 10mm, and the bottom is a tapered outlet b, which is beneficial to the smooth discharge of solid products.

[0085] The supercritical water heating electric furnace a is controlled by four stages of control points a-1, a-2, a-3, and a-4, which can realize uniform and adjustable temperature. The coal slurry preheater d is a trumpet-shaped tube with a thin upper part and a thicker bottom part. The inner diameter is 5mm at the thickest part. The water inlet g of the supercritical water reactor has a filter membrane, and the outlet c of the supercritical water reactor has a filter membrane with a pore size of 1 μm.

[0086] The outlet c of the supercritical water reactor at the top of the supercritical water reactor e is provided with a filter membrane, and the filter membrane aperture is 1 μm to prevent solid materials from being taken out of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com