System and method for producing hydrogen by collecting solar energy in multi-plate mode and coupling biomass supercritical water gasification

A technology of supercritical water gasification and solar heat concentrating, which is applied in the fields of chemical instruments and methods, hydrogen, inorganic chemistry, etc. It can solve the difficult conditions of rapid temperature rise of gasification reaction and a large amount of heat, and it is effective without comprehensive consideration of energy cascades. Recycling, low energy conversion efficiency of the system, etc., to achieve the effect of improving biomass gasification rate, large focusing ratio, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

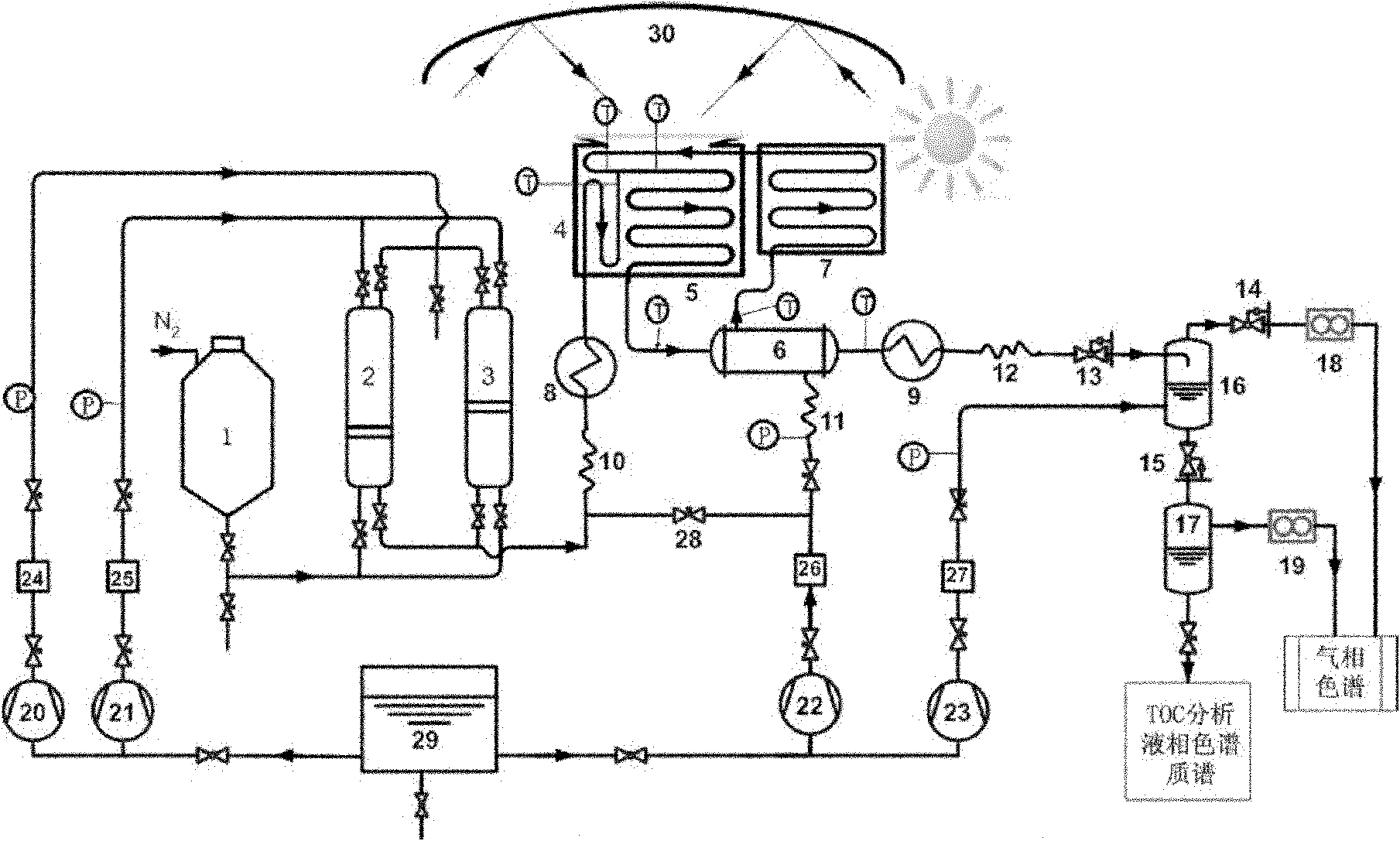

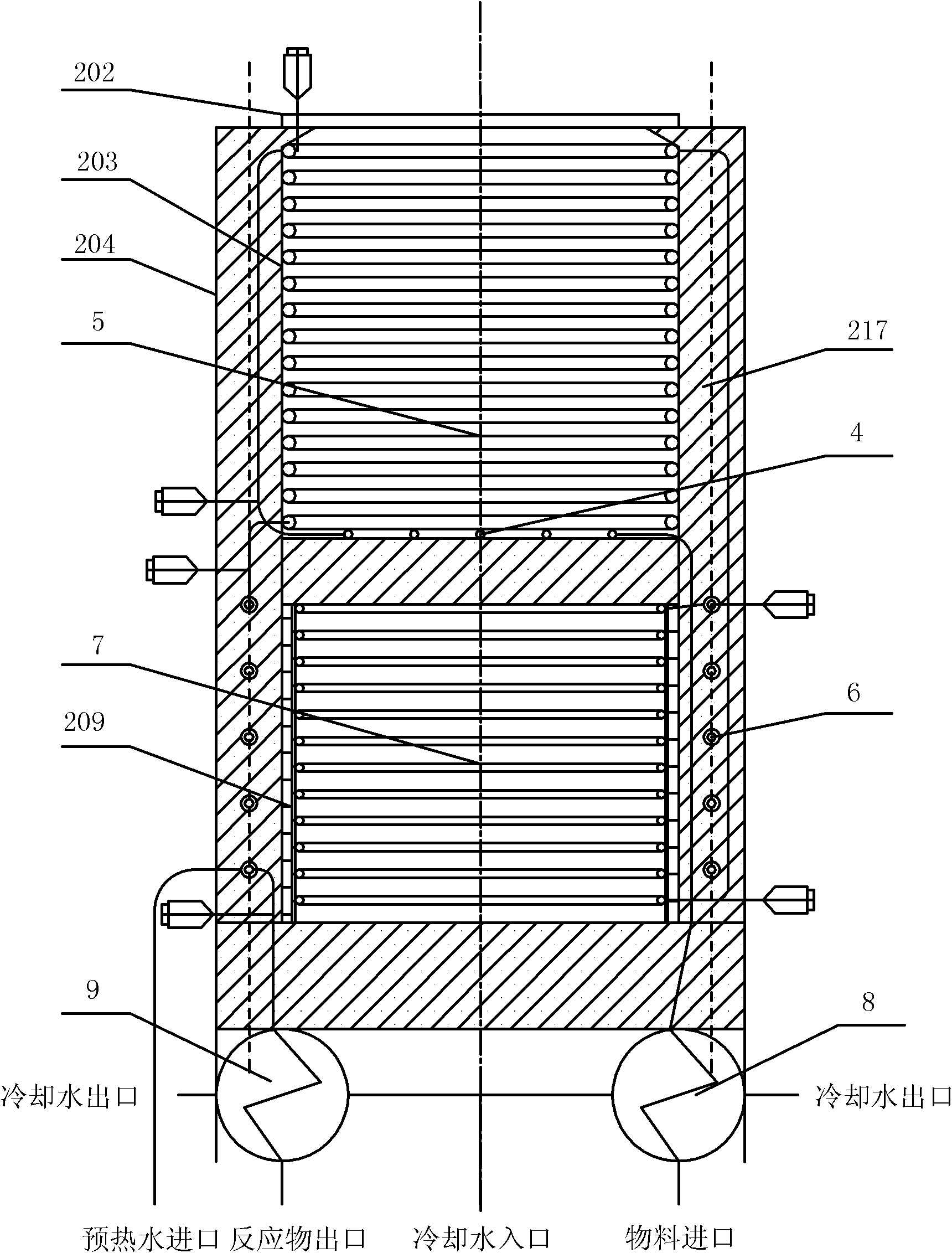

[0033] see figure 1 , the multi-disk solar heat concentrating coupled biomass supercritical water gasification hydrogen production system of the present invention includes a material high-pressure delivery system for high-pressure continuous delivery of biomass slurry, which is used to absorb and gather solar heat to drive biomass supercritical water gas A cavity type solar energy absorption supercritical water reactor for the hydrogen production reaction, a multi-disk automatic tracking solar concentrating heat collector 30 and a gas-water separation device for providing heat sources for the cavity type solar energy absorption supercritical water reactor. The material output end of the material high-pressure conveying system is connected to the material input end of the cavity type solar energy absorption supercritical water reactor, and the output end of the cavity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com