Energy gradient utilization system and method for supercritical water gasification hydrogen production process

A technology of supercritical water gasification and supercritical water, which is applied in the gasification process, granular/powdered fuel gasification, petroleum industry, etc., and can solve the problem of limited temperature resistance limit, low hydrogen production efficiency, and polycyclic aromatic hydrocarbons. Compounds cannot be degraded and other problems, to achieve the effect of increasing the operating temperature, efficient utilization, and ensuring high temperature supercritical water gasification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

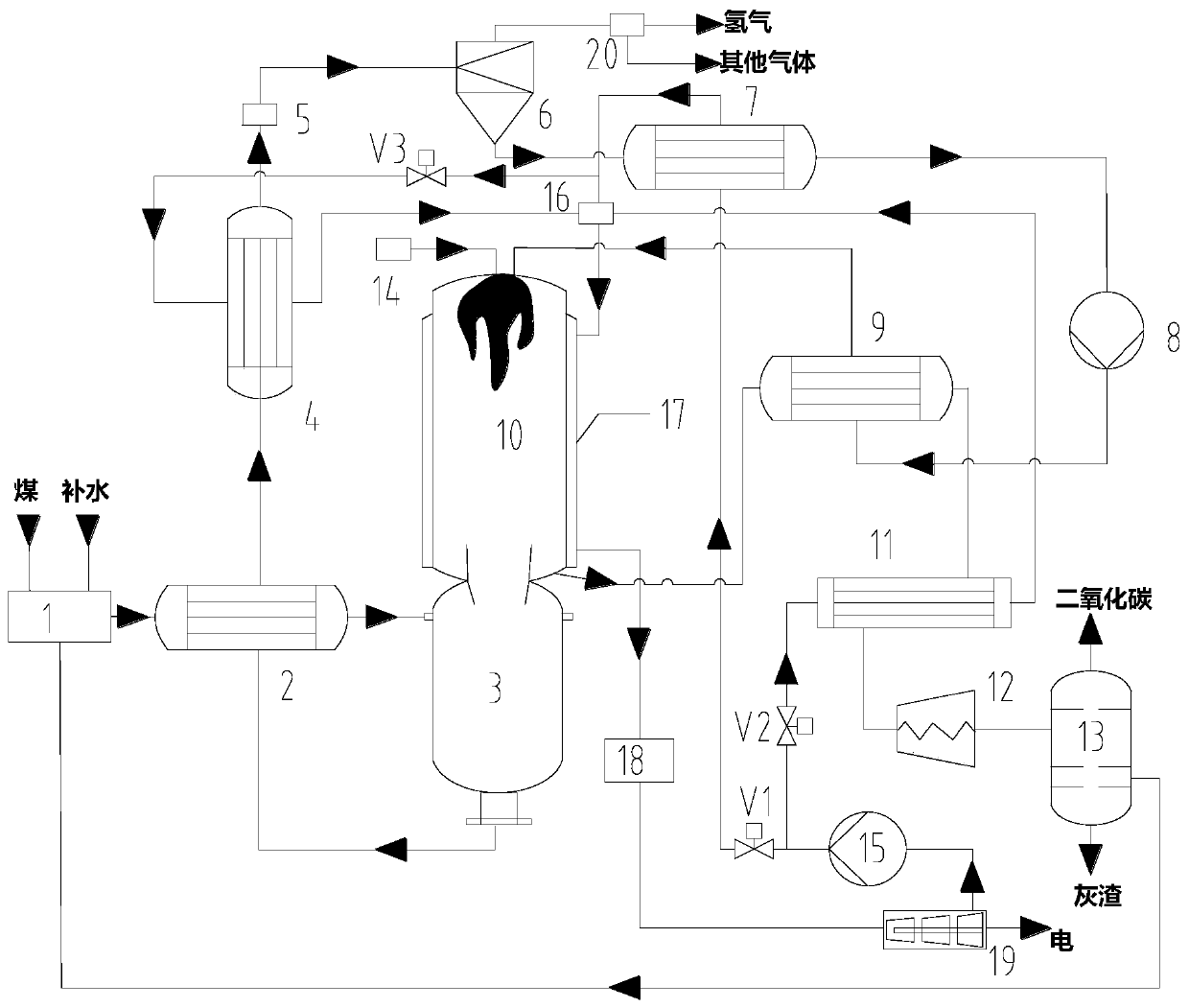

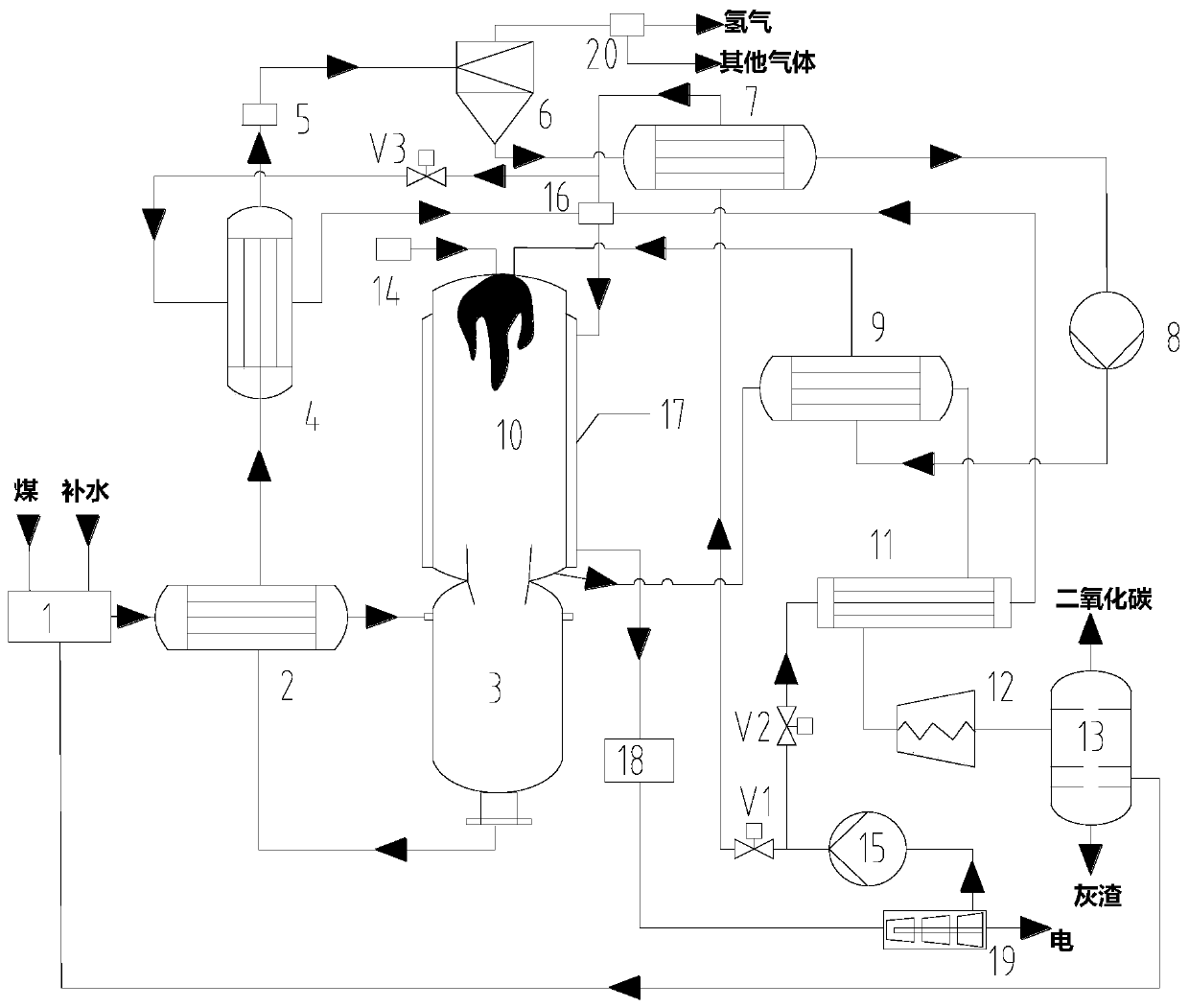

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0020] The present invention is based on following principle and train of thought:

[0021] The flame produced by supercritical hydrothermal combustion in water above the critical point is called hydrothermal flame, which is a more violent oxidation reaction. The local high temperature of the supercritical hydrothermal flame can reach more than 1000 °C, which is extremely beneficial to accelerate the oxidative degradation of organic matter, and at the same time, its large amount of high-grade heat energy has a high potential for utilization. Supercritical water gasification of coal to produce hydrogen, and the carbon residue-containing slurry after separating hydrogen-rich gas from the gasification product is used as a raw material for supercritical hydrothermal combustion, which can realize the complete energy utilization and harmless treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com