Combined method for treating kitchen waste and waste plastics to prepare hydrogen-rich fuel gas

A technology for kitchen waste and waste plastics, applied in the manufacture of combustible gas, granular/powder fuel gasification, fuel and other directions, can solve problems such as plastic waste disposal problems, achieve efficient treatment, reduce secondary pollution, and high hydrogen concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

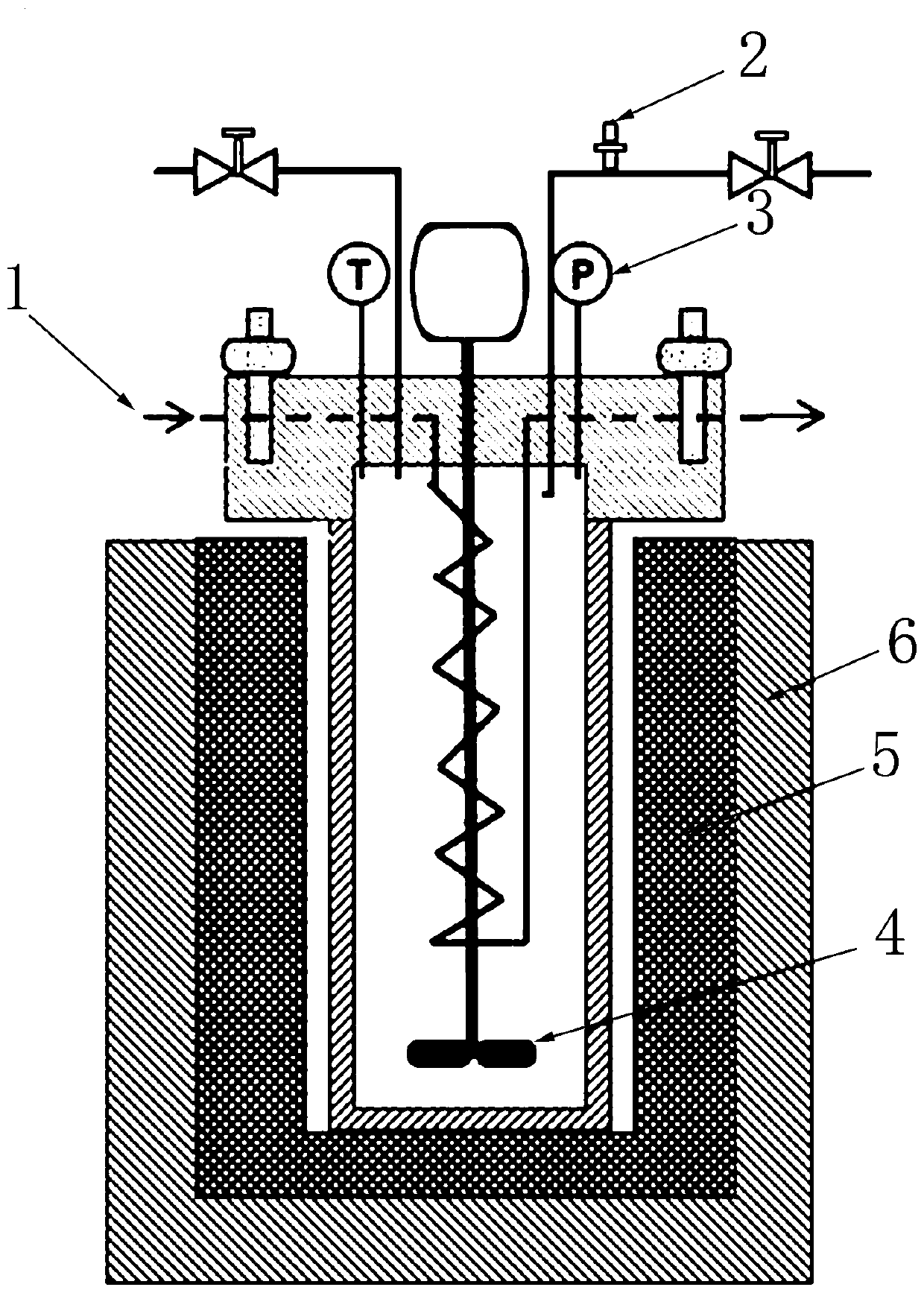

Method used

Image

Examples

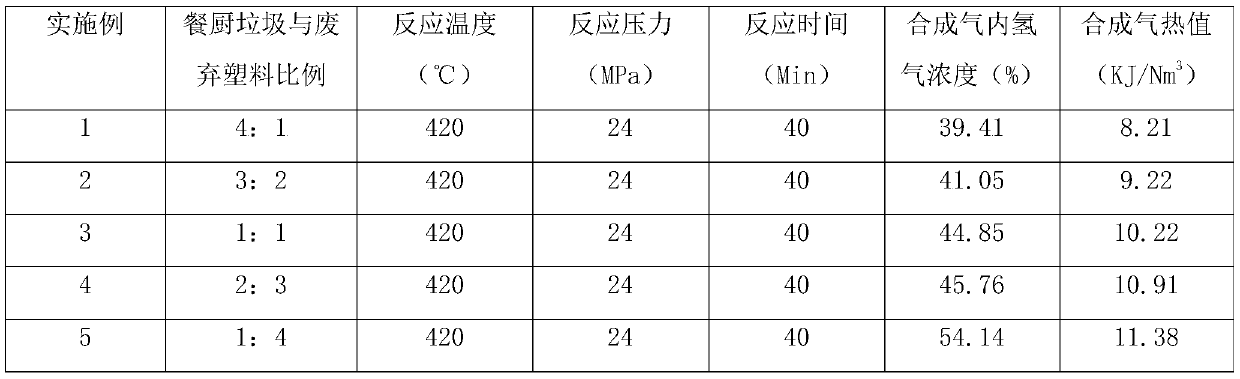

Embodiment 1

[0027] Mix food waste and waste plastics in a ratio of 4:1 and transport them to the reactor, add water to the material to a water content of 90%, use pure nitrogen to discharge the air in the reactor, so that the reaction is carried out under a nitrogen atmosphere, and the reaction The reactor was heated and pressurized to 420°C and 24MPa and maintained for 40 minutes. After the reaction was completed, the reactor was cooled and pressurized with cooling water. High quality gas collection. The gas phase components are shown in Table 1.

Embodiment 2

[0029] Mix food waste and waste plastics in a ratio of 3:2 and transport them to the reactor, add water to the material to a water content of 90%, use pure nitrogen to discharge the air in the reactor, so that the reaction is carried out under a nitrogen atmosphere, and the reaction The reactor was heated and pressurized to 420°C and 24MPa and maintained for 40 minutes. After the reaction was completed, the reactor was cooled and pressurized with cooling water. High quality gas collection. The gas phase components are shown in Table 1.

Embodiment 3

[0031] Mix food waste and waste plastics in a ratio of 1:1 and transport them to the reactor, add water to the material to a water content of 90%, use pure nitrogen to discharge the air in the reactor, so that the reaction is carried out under a nitrogen atmosphere, and the reaction The reactor was heated and pressurized to 420°C and 24MPa and maintained for 40 minutes. After the reaction was completed, the reactor was cooled and pressurized with cooling water. High quality gas collection. The gas phase components are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com