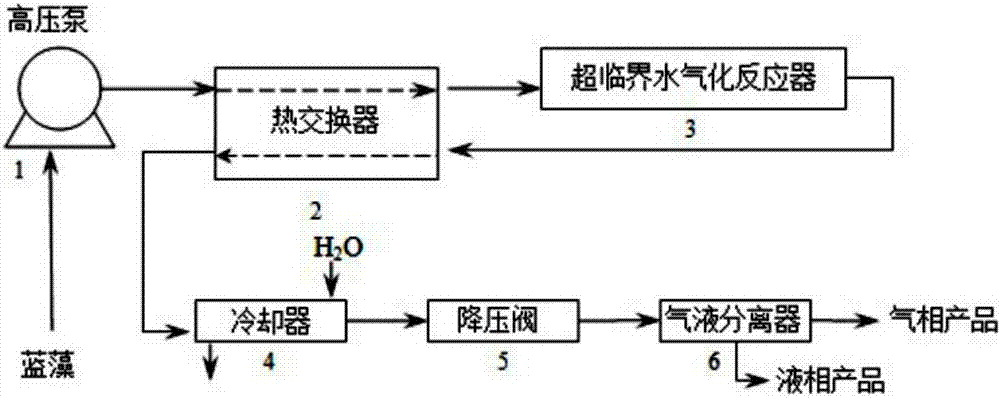

Spherical titanium dioxide catalyst and application thereof to preparation of hydrogen through supercritical water gasification by taking cyanobacteria as raw material

A titanium dioxide and spherical technology, applied in the field of resource engineering, can solve the problems of low hydrogen output, low hydrogen selectivity, and low hydrogen purity, and achieve the effects of efficient utilization, uniform particle size, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: preparation embodiment, the preparation of spherical titanium dioxide of the present invention

[0029] It is prepared by the following steps: first dissolve titanium sulfate and urea in an aqueous solution of isopropanol with a volume concentration of 30%, then place it in a polytetrafluoroethylene liner reactor, and conduct a hydrothermal reaction at 180°C for 15 hours. Cool and centrifuge to collect the precipitate, wash the precipitate with ethanol and water three times respectively, and dry at 70°C for 5 hours after washing. Wherein, the molar concentration of titanium sulfate is 2 mol / L, and the molar concentration of urea is 1.5 times of the molar concentration of titanium sulfate.

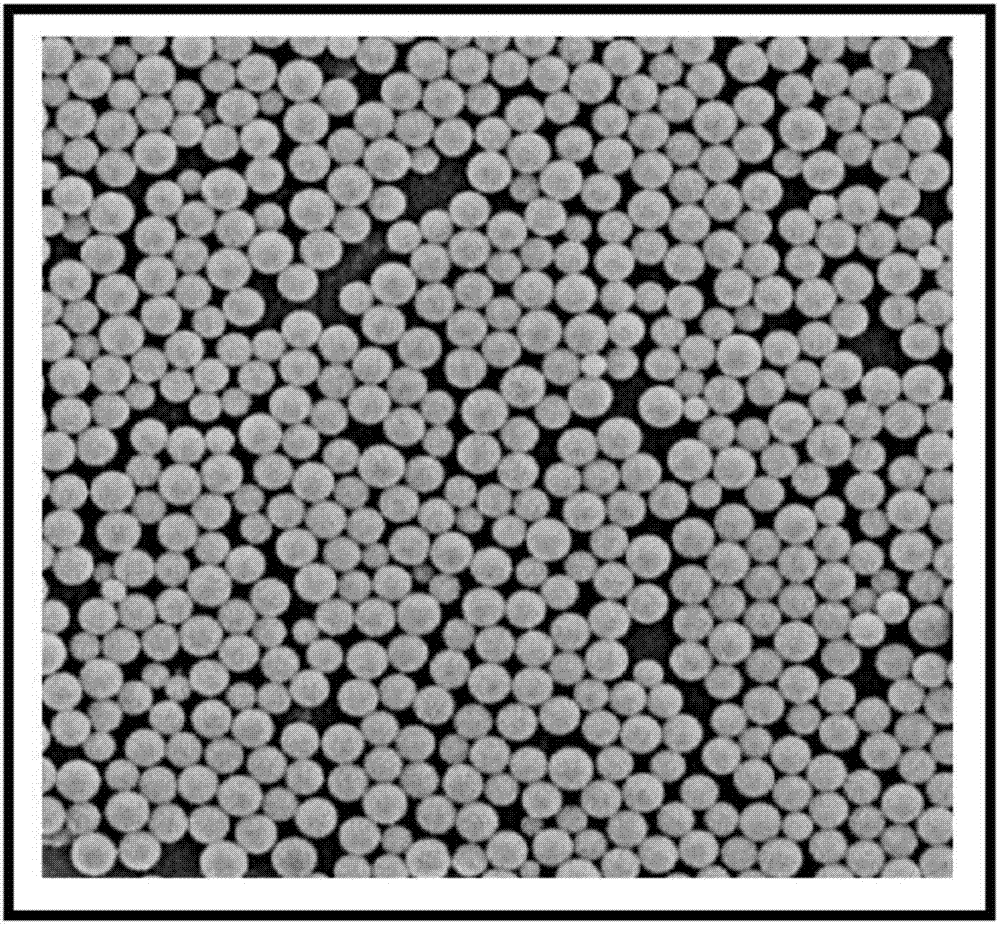

[0030] figure 2 It is the SEM scanning electron microscope picture of titanium dioxide product. It can be seen from the picture that it is a regular spherical shape with high uniformity and the particle size is between 600-800nm.

Embodiment 2

[0031] Embodiment 2: preparation embodiment, the preparation of spherical titanium dioxide of the present invention

[0032] It is prepared by the following steps: first dissolve titanium sulfate and urea in an aqueous solution of isopropanol with a volume concentration of 25%, then place it in a polytetrafluoroethylene-lined reactor, and conduct a hydrothermal reaction at 170°C for 16 hours. Cool and centrifuge to collect the precipitate, wash the precipitate twice with ethanol and water successively, and dry at 60°C for 6 hours after washing. Wherein, the molar concentration of titanium sulfate is 1.8 mol / L, and the molar concentration of urea is 1 time of the molar concentration of titanium sulfate.

[0033] The SEM scanning electron microscope observation result of titanium dioxide product is the same as embodiment 1.

Embodiment 3

[0034] Embodiment 3: preparation embodiment, the preparation of spherical titanium dioxide of the present invention

[0035] It is prepared by the following steps: first dissolve titanium sulfate and urea in an aqueous solution of isopropanol with a volume concentration of 35%, then place it in a polytetrafluoroethylene liner reactor, and conduct a hydrothermal reaction at 190°C for 14 hours. Cool and centrifuge, collect the precipitate, wash the precipitate with ethanol and water three times respectively, and dry at 80°C for 4 hours after washing. Wherein, the molar concentration of titanium sulfate is 2.2 mol / L, and the molar concentration of urea is twice of the molar concentration of titanium sulfate.

[0036] The SEM scanning electron microscope observation result of titanium dioxide product is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com