Two-step organic waste treatment system and method based on supercritical/subcritical water technology

A technology for organic waste and subcritical water, applied in the field of organic waste treatment systems, can solve the problems of inability to control liquefaction reaction products alone, low conversion rate of gasified organic matter, difficult gasification of organic matter, etc. The effect of conversion efficiency, improving gasification rate and reducing waste disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

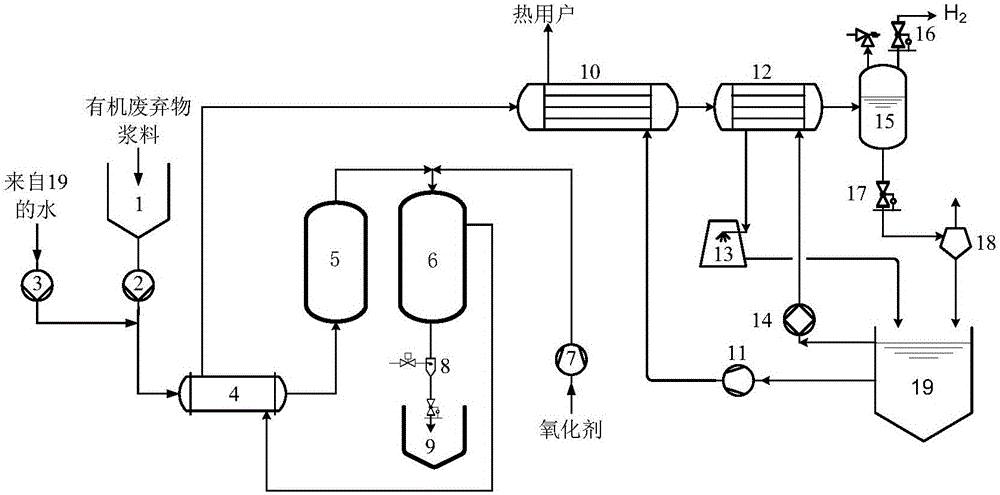

[0043] Using a two-step treatment method for organic waste based on super / subcritical water technology, using 20wt% food waste slurry as the material, the specific process is as follows:

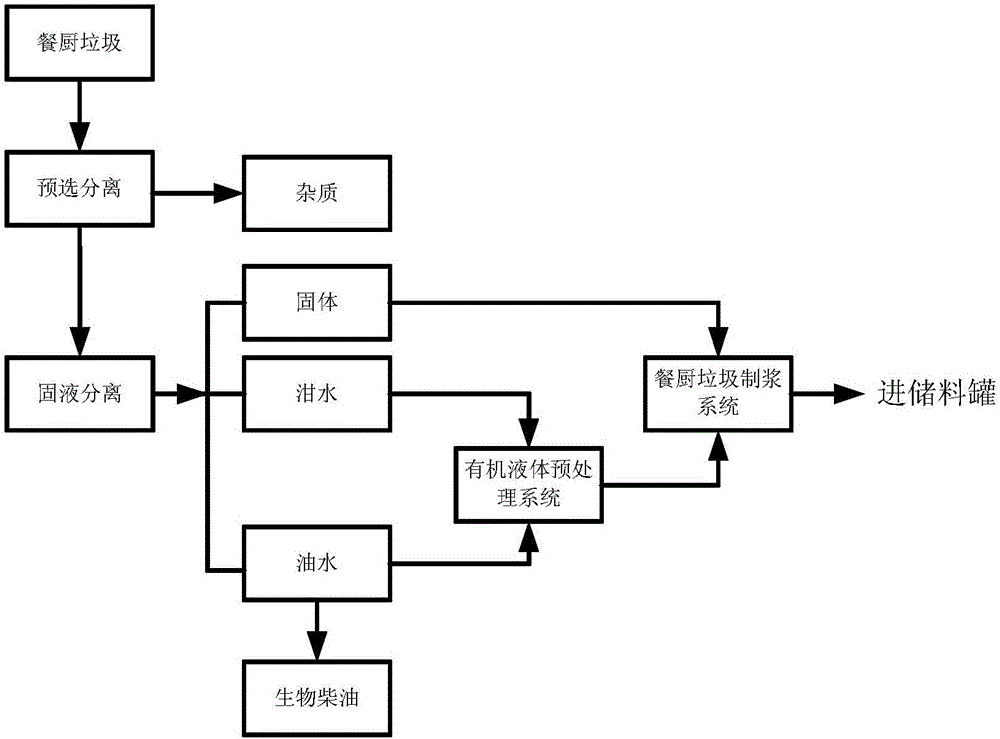

[0044] 1) pre-treating the kitchen waste, performing pre-selection and separation, and after solid-liquid separation, making the organic waste into a slurry with a certain fluidity and a concentration of 20 wt%, and sending the slurry into the storage mixing tank 1;

[0045] 2) Open the bypass water pump 3, adjust the first back pressure valve 16 and the second back pressure valve 17, make the system pressure reach the preset value; open the starting heating device in the subcritical hydrolysis reactor 5 and the supercritical water reactor 6 , so that the temperature in the subcritical hydrolysis reactor 5 and the supercritical water gasification reactor 6 reaches a preset value; open the slurry pump 2 and close the bypass water pump 3, and adjust the slurry flow to reach a preset value;

[...

Embodiment 2

[0051] Using a two-step treatment method for organic waste based on super / subcritical water technology, using 15wt% alkali lignin as a material, the specific process is as follows:

[0052] 1) mixing the alkali lignin raw material with water and an ionic liquid catalyst to make a slurry with a certain fluidity and a mass concentration of 15 wt%, and sending the slurry into the storage mixing tank 1;

[0053]2) Open the bypass water pump 3, adjust the first back pressure valve 16 and the second back pressure valve 17, make the system pressure reach the preset value; open the starting heating device in the subcritical hydrolysis reactor 5 and the supercritical water reactor 6 , so that the temperature in the subcritical hydrolysis reactor 5 and the supercritical water gasification reactor 6 reaches a preset value; open the slurry pump 2 and close the bypass water pump 3, and adjust the slurry flow to reach a preset value;

[0054] 3) The slurry passes through the material heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com