Comprehensive method and system for utilizing carbon-contained organic matter

An integrated method, integrated system technology, applied in microorganism-based methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as high cost and inability to reduce carbon dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Take dry coal powder with a particle size of less than 75 μm, configure it into a 10-30 wt% slurry, then add a potassium carbonate catalyst with a dry coal mass fraction of 10%, and stir evenly;

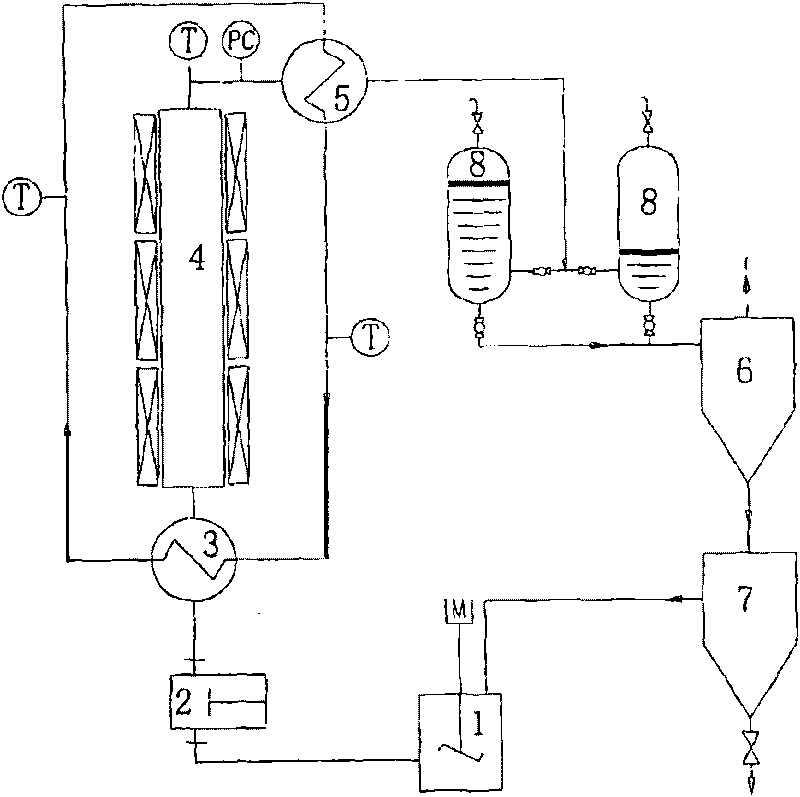

[0133] Turn on the high-pressure pump 2 to pressurize the whole device with water until the pressure in the reactor rises to 25MPa or 30MPa, then pump the slurry into it. After the system pressure is stabilized, turn on the heating power of the reactor and set the central temperature of the reactor to 650°C or 550°C, set the preheating temperature of the coal-water slurry to a maximum of 300°C. The preheated slurry reacts quickly in the reactor, and the residence time is 30 seconds to 1 minute. The reaction product is cooled to 80°C by the cooler 5 and enters one of the buffer tanks 8. After the buffer tank is full, switch to another buffer tank, and then depressurize the full buffer tank. The reaction product after depressurization Enter the first separator 6 for gas / liquid-...

Embodiment 2

[0137] Grind the sunflower stalks and microalgae residues to below 80 meshes, make a slurry with a concentration of 20wt% with water, add it to the slurry storage tank 1, and then add a K-Ni composite catalyst loaded on a carrier with a dry powder mass fraction of 5%, Stir well.

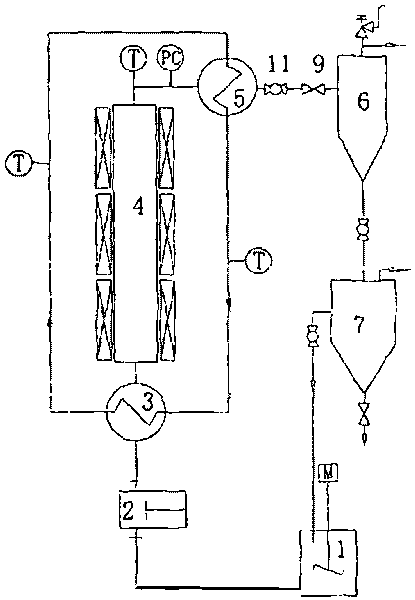

[0138] Turn on the high-pressure pump 2 to pressurize the system with water until the system pressure rises to 25MPa, then pump the slurry in. After the system pressure is stable, turn on the heating power of the reactor 4 and set the central temperature of the reactor to 350°C or 400°C , set the pulp preheating temperature up to 200°C. The preheated slurry reacts rapidly in the reactor, and the residence time is 1-10 minutes. The reaction product is cooled to 80°C by the cooler 5 and then enters the first separator 6 for gas / liquid-solid separation, and the gas product obtained is discharged from the top opening of the separator, and a safety valve can be set on the gas pipeline according to the ne...

Embodiment 3

[0142] The residual oil obtained by crude oil distillation under reduced pressure, together with water and surfactants, is formulated into a slurry with a concentration of 30-40wt%, which is added to the slurry storage tank 1, and then 15% of the weight of the residual oil is added to be loaded on the carrier K-Ni composite catalyst, stir evenly.

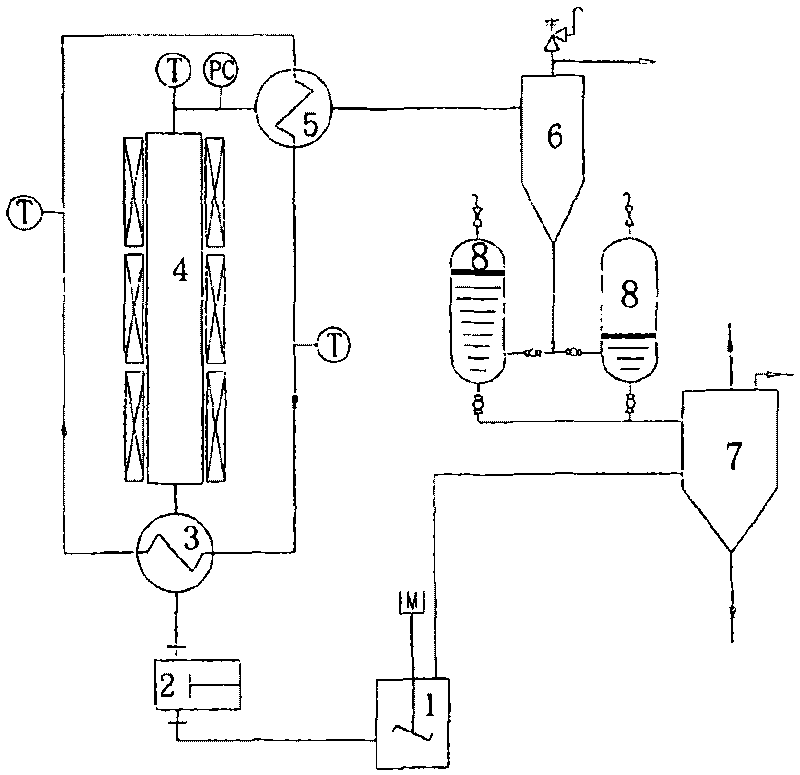

[0143] Turn on the high-pressure pump 2 to pressurize the system with water until the system pressure rises to 28MPa, then pump the slurry in. After the system pressure is stabilized, turn on the heating power of the reactor 4, set the central temperature of the reactor to 600°C, and set The maximum pulp preheating temperature is 200°C. The preheated slurry reacts rapidly in the reactor, and the residence time is 2 minutes. The reaction product is cooled to 80°C by the cooler 5 and then enters the first separator 6 for gas / liquid-solid separation, and the gas product obtained is discharged from the top opening of the separator, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com