Aerogel material composed of fibers and adhesive, and preparation method and application thereof

A binder and airgel technology, applied in the field of airgel materials and its preparation, can solve the problems of fiber-based airgel preparation methods and performance limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

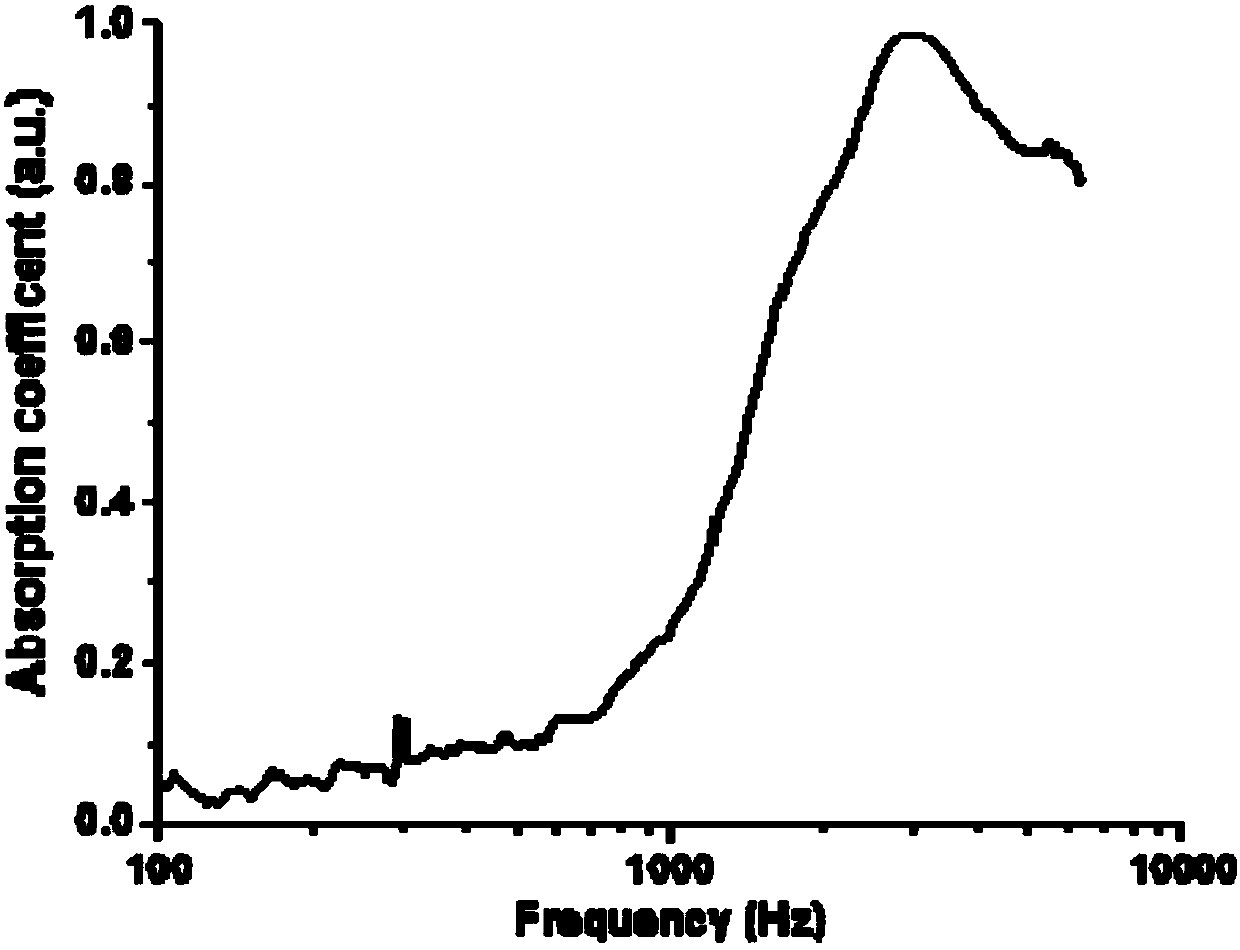

[0048] Dissolve the binder starch in water to form a homogeneous solution; disperse cotton fibers with an average diameter of 5 μm and an aspect ratio of 10,000 in the above solution to form a suspension; the mass fraction of cotton fibers in the suspension is 10 %, the mass fraction of binder starch is 2%. The suspension is aged at room temperature for 10 hours to obtain a solidified body; the solid water in the solidified body is removed by freeze-drying to obtain an adhesive / fiber aerogel. The apparent density of the airgel material is 0.1g / cm 3 , the average pore size is 100μm, and the sound absorption coefficient is as image 3 shown.

Embodiment 2

[0050] The binder precursor benzoxazine is dissolved in dioxane to form a homogeneous solution; the polyimide fiber with an average diameter of 200nm and an aspect ratio of 5000 is dispersed in the above solution to form a suspension; the The mass fraction of the polyimide fiber in the suspension is 1%, and the mass fraction of the binder precursor benzoxazine is 0.2%. Freeze the suspension at -4°C for 2 hours to obtain a solidified body; use freeze-drying to remove the solid dioxane in the solidified body to obtain a binder precursor fiber aerogel; thermally polymerize at 200°C Treat for 2h to polymerize the binder precursor to obtain the binder / fiber aerogel. The apparent density of the airgel material is 10mg / cm 3 , with an average pore size of 50 μm and good tensile properties (such as Figure 4 shown), excellent twisting performance and bending performance, and its microscopic morphology is as follows Figure 7-9 shown.

Embodiment 3

[0052] Dissolve the adhesive polyurethane in tert-butanol to form a homogeneous solution; disperse silica fibers with an average diameter of 300nm and an aspect ratio of 8000 in the above solution to form a suspension; The mass fraction of silicon fiber is 20%, and the mass fraction of adhesive polyurethane is 5%. The suspension was subjected to sol-gelation treatment at 50° C. for 24 hours to obtain a solidified body; the solid tert-butanol in the solidified body was removed by vacuum drying to obtain an adhesive / fiber airgel. The apparent density of the airgel material is 0.2g / cm 3 , with an average pore size of 5 μm and good tensile properties (such as Figure 5 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com