Method for gasifying unsymmetrical dimethylhydrazine waste liquor through supercritical water

A technology of supercritical water gasification and unsymmetrical dimethyl hydrazine, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of secondary pollution, high toxicity, etc. The effect of large processing capacity and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

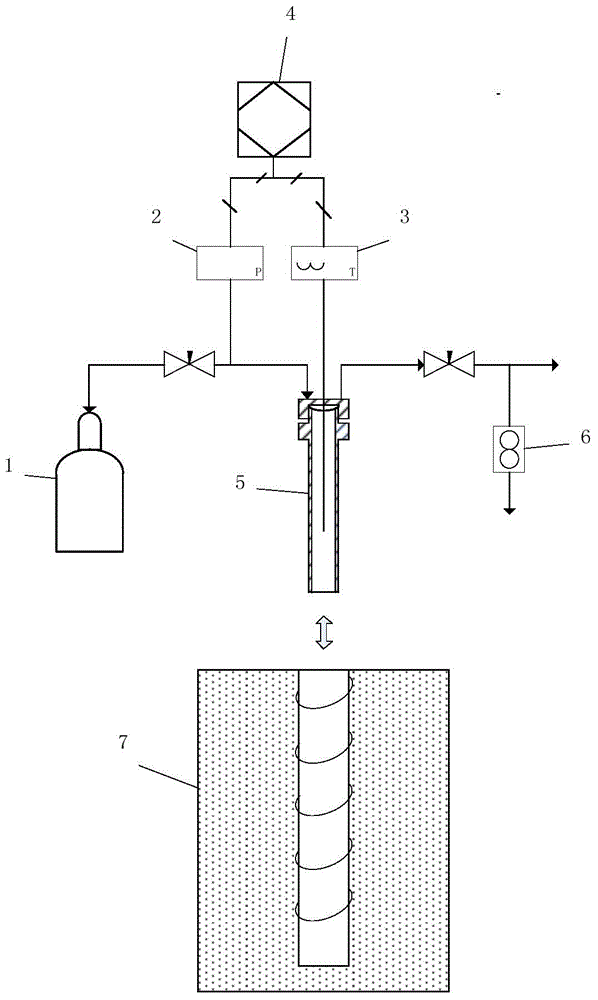

Image

Examples

Embodiment 1

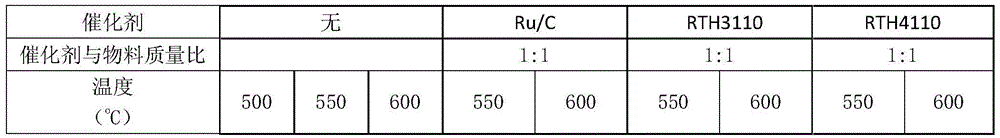

[0036] Example 1 Utilize Ru / C and skeleton nickel in supercritical water to make catalyst gasification unsymmetrical dimethylhydrazine

[0037]In the catalytic gasification experiment of unsymmetrical dimethylhydrazine, the following three catalysts with better catalytic gasification results under supercritical water conditions were selected: carbon-supported ruthenium (Ru / C), Raney nickel 3110 (RTH3110) , Raney Nickel 4110 (RTH4110). It can be seen from Table 1-1 that when no catalyst is added, as the temperature increases from 550°C to 600°C, H 2 The mole fraction of CH gradually increased, CH 4 The mole fraction of gradually decreases, when the catalyst is added, compared with no catalyst, the H 2 The mole fraction of H has been significantly increased. As the temperature increases from 550°C to 600°C, H 2 The mole fraction of CH gradually decreases, CH 4 The mole fraction of the gradually increased. h 2 and CH 4 The output of the same law with the increase of temper...

Embodiment 2

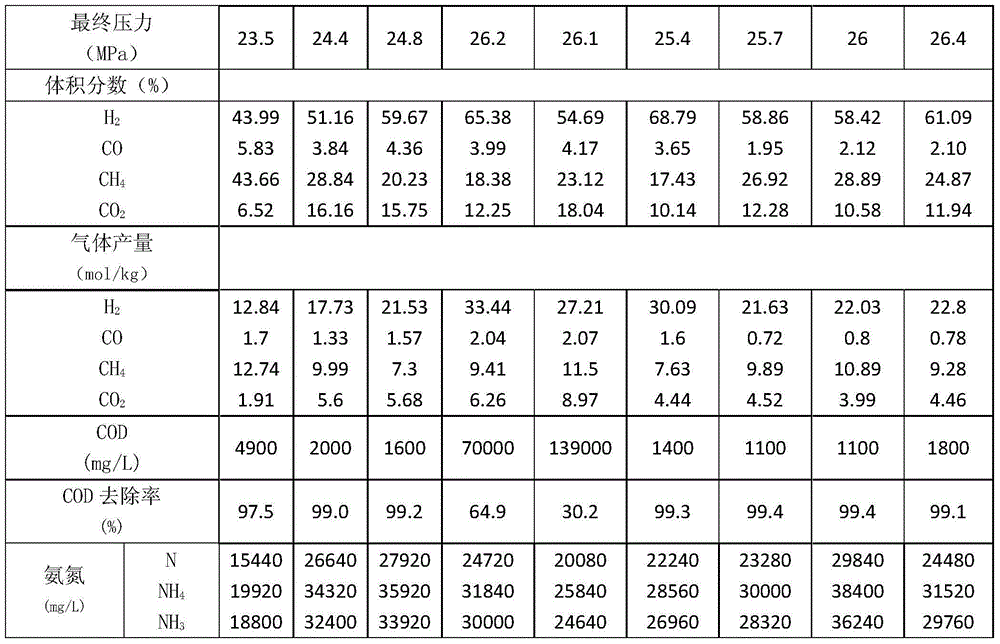

[0042] The impact of different oxidant concentrations in embodiment 2 supercritical water on degrading unsymmetrical dimethylhydrazine

[0043] In the partial oxidation gasification experiment of unsymmetrical dimethylhydrazine, the selected oxidant is H 2 o 2 . It can be seen from Table 1-2 that when no oxidant is added, as the temperature increases from 500°C to 600°C, H 2 The mole fraction of CH gradually increased, CH 4 The mole fraction of H gradually decreases, and as the amount of oxidant increases, H 2 and CH 4 The mole fraction and yield of CO gradually decrease, while the CO 2 The mole fraction and yield gradually increased.

[0044] In terms of COD removal rate, as the amount of oxidant increases, its COD removal rate increases gradually, all above 99%, and its ammonia nitrogen content gradually decreases with the addition of oxidant.

[0045] Table 1-2 Partial oxidation treatment results of unsymmetrical dimethylhydrazine

[0046] (material quality (unsymme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com