Biomass supercritical water gasification hydrogen production system and method thermally driven by focusing solar energy

A supercritical water gasification, solar thermal technology, applied in chemical instruments and methods, hydrogen production, hydrogen, etc., to achieve the effects of enhanced stability, simplified system, and increased heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

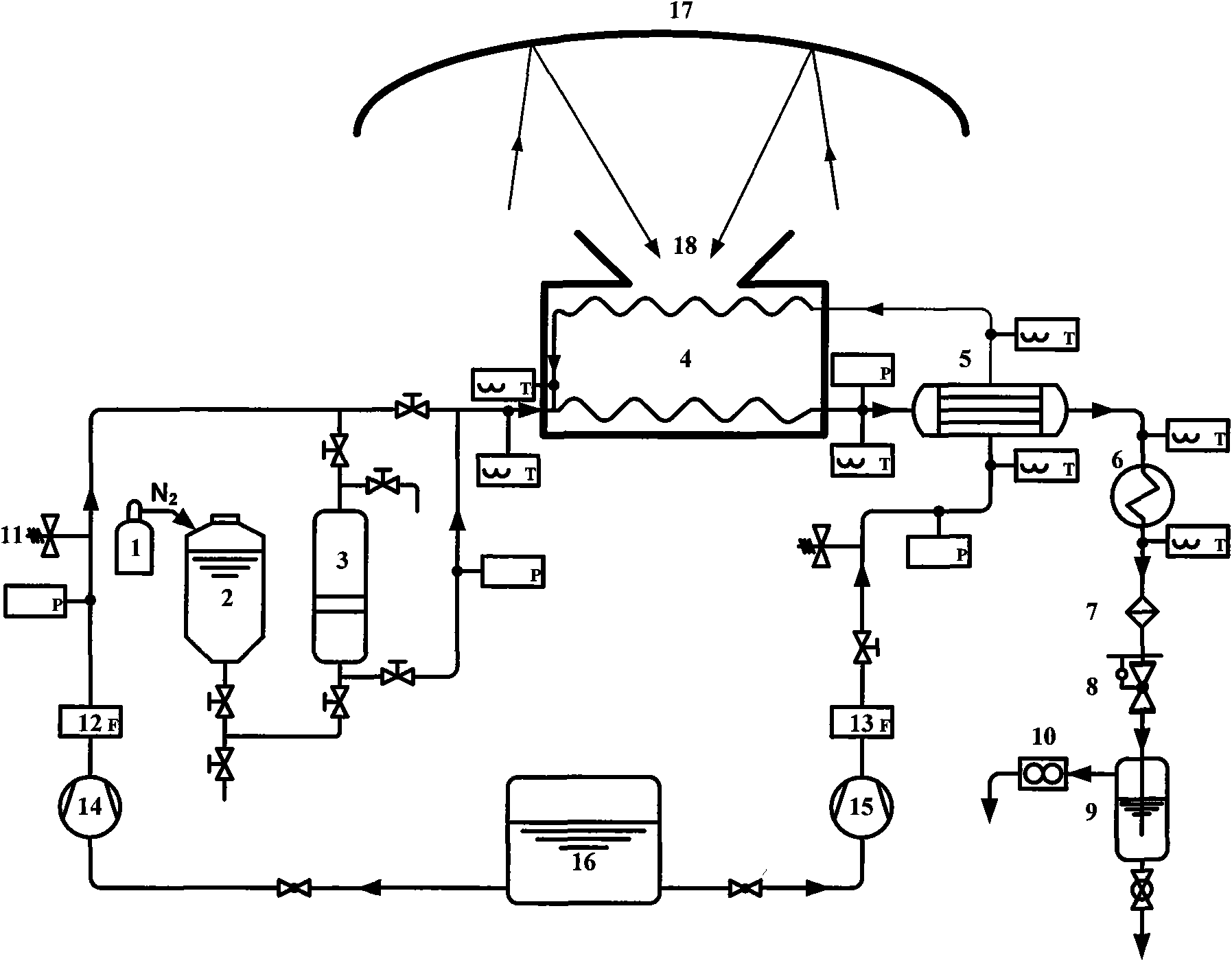

Method used

Image

Examples

Embodiment

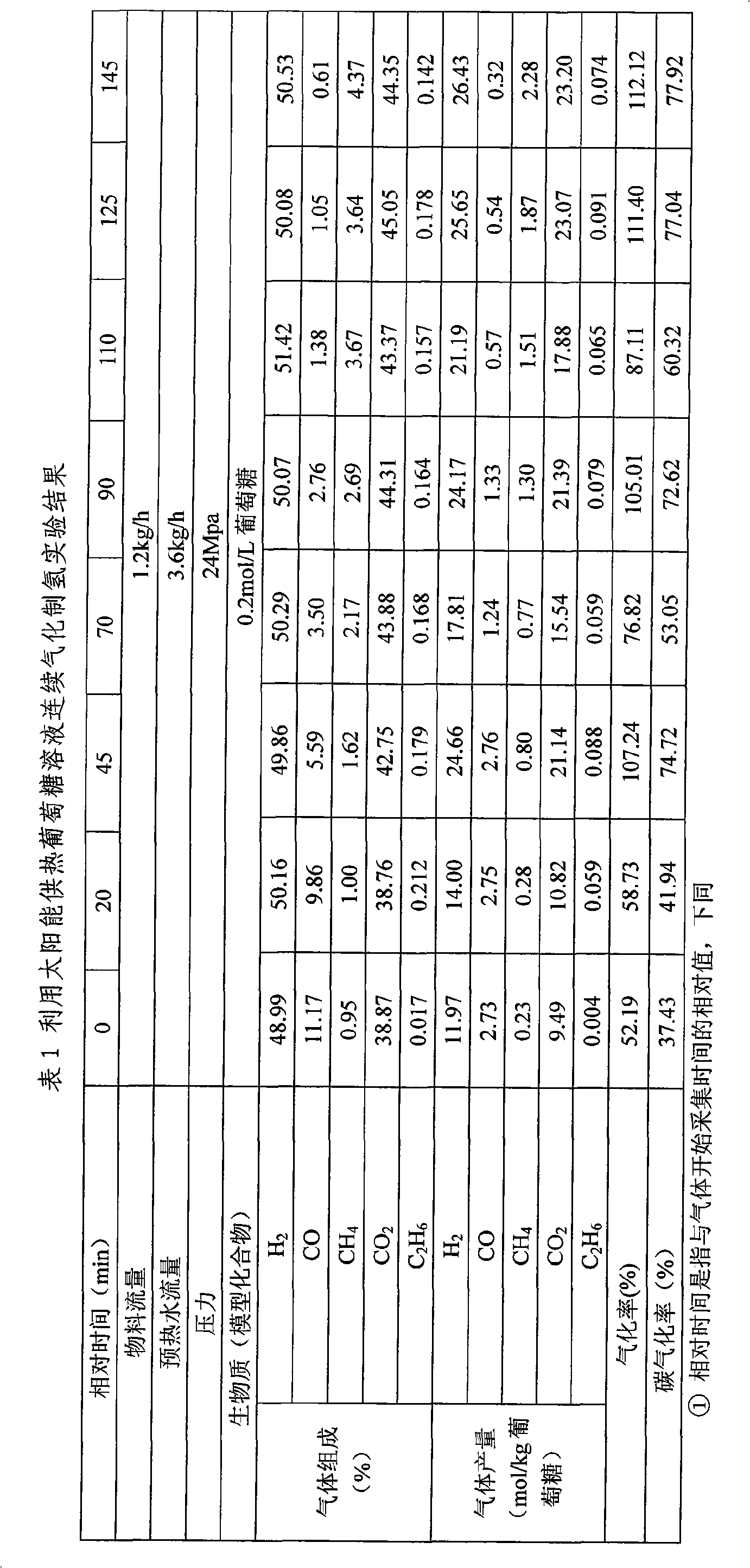

[0044] Table 1 shows the experimental results of continuous gasification of glucose solution for hydrogen production using solar energy heating

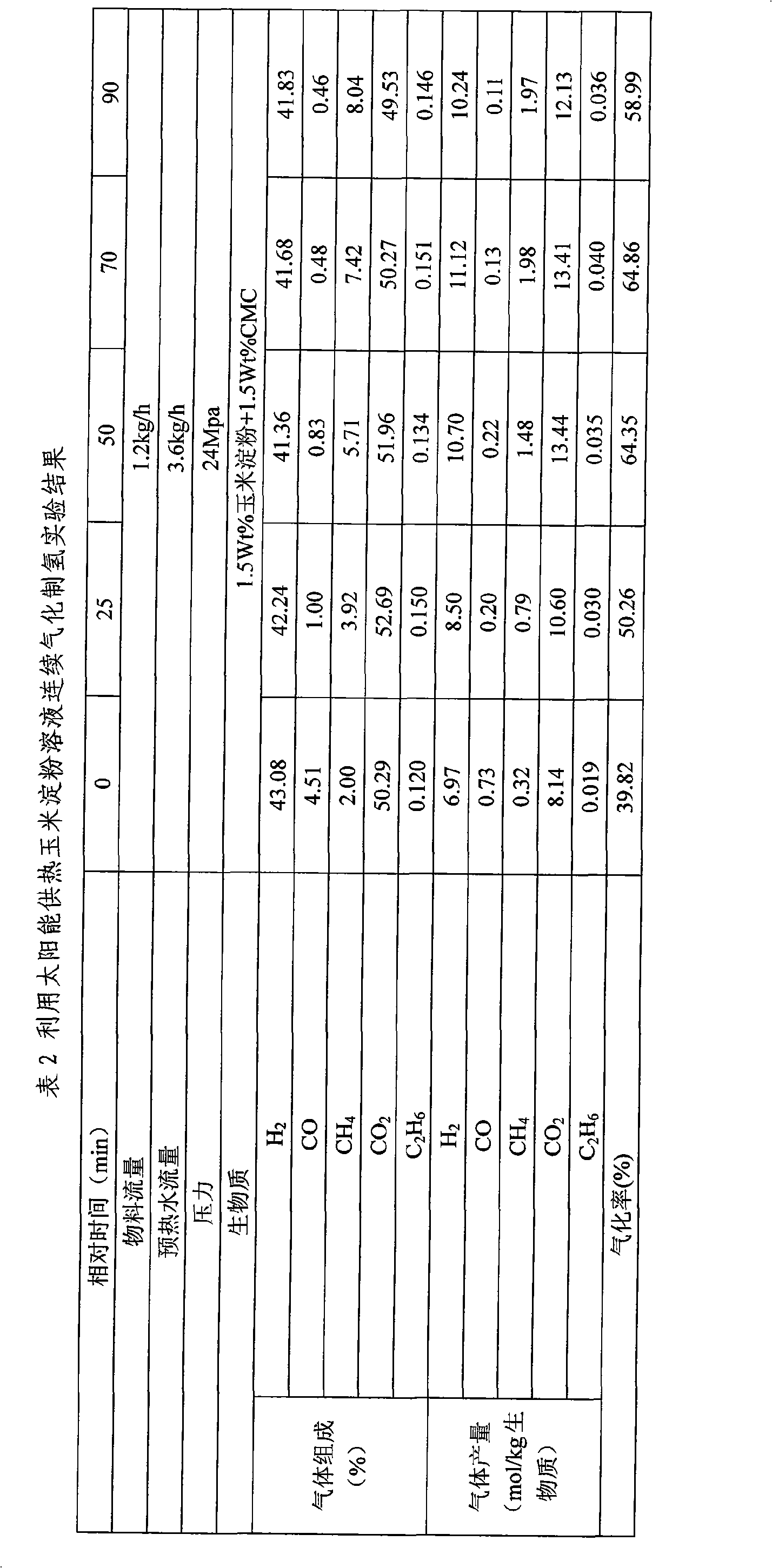

[0045] Table 2 shows the experimental results of continuous gasification of cornstarch solution for hydrogen production using solar energy heating

[0046] In the table: gasification rate = mass of gas product / mass of biomass participating in the reaction × 100%

[0047] Carbon gasification rate = carbon element mass of gasification product / mass carbon element of biomass participating in the reaction × 100%

[0048] Table 1 shows the experimental results of hydrogen production by continuous gasification of glucose solution using solar energy. The experimental conditions are: the average direct solar radiation intensity in Xi'an on that day is 710w / m 2 , the focal area of the heliostat is 16m 2 , the pressure is 24Mpa, the biomass model compound is a glucose solution with a concentration of 0.2mol / L, and continuous gas collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com