Method for preparing hydrogen by utilizing waste biomass

A waste biomass and biomass technology, applied in the manufacture of combustible gas, chemical instruments and methods, and catalytic treatment of combustible gas, can solve the problems of high energy consumption, high reaction temperature, and high pressure in the process, and reduce the reaction temperature , Simple preparation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

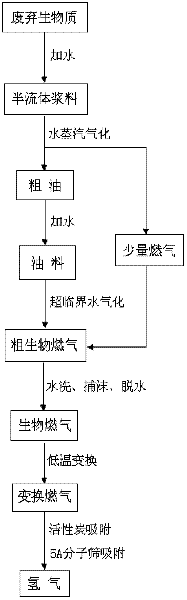

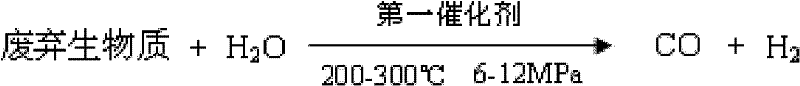

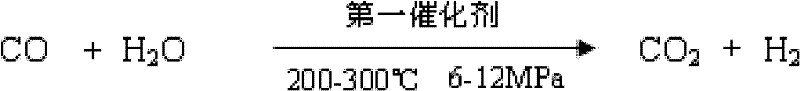

Method used

Image

Examples

Embodiment 1

[0052] 1. Preparation of catalyst

[0053] 1) Preparation of the first catalyst

[0054] Sodium carbonate and lanthanum nitrate are mechanically mixed to obtain the first catalyst, and the molar ratio of sodium carbonate and lanthanum nitrate in the first catalyst is 16:1;

[0055] 2) Preparation of the second catalyst

[0056] Sodium carbonate, nickel nitrate, and lanthanum nitrate are mechanically mixed to obtain a second catalyst, and the molar ratio between sodium carbonate, nickel nitrate and lanthanum nitrate in the second catalyst is 16:10:1;

[0057] 3) Preparation of copper-zinc-aluminum-precious metal rare earth composite catalyst

[0058] 181.2kg copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 125.6kg zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 18.4 aluminum nitrate (Al(NO 3 ) 3 9H 2 O) be dissolved in distilled water, make mixed nitrate solution; Under room temperature and stirring condition, mix nitrate solution and the sodium carbonate solution of 1mol / L and flow dro...

Embodiment 2

[0097] 1. Preparation of catalyst

[0098] 1) Preparation of the first catalyst

[0099] Potassium carbonate and cerium nitrate are mechanically mixed to obtain the first catalyst, and the molar ratio of potassium carbonate and cerium nitrate in the first catalyst is 10:1;

[0100] 2) Preparation of the second catalyst

[0101] Potassium carbonate, nickel nitrate, and cerium nitrate are mechanically mixed to obtain a second catalyst, and the molar ratio between potassium carbonate, nickel nitrate and cerium nitrate in the second catalyst is 10:8:1;

[0102] 3) Preparation of copper-zinc-aluminum-rare earth precious metal composite catalyst

[0103] 151kg copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 128.5kg zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 51.5 aluminum nitrate (Al(NO 3 ) 3 9H 2 O) be dissolved in distilled water, make mixed nitrate solution; Under room temperature and stirring condition, mix nitrate solution and the sodium carbonate solution of 1mol / L and flow drop i...

Embodiment 3

[0130] 1. Preparation of catalyst

[0131] 1) Preparation of the first catalyst

[0132] Mechanically mixing calcium carbonate and cerium nitrate to obtain a first catalyst, the molar ratio of calcium carbonate and cerium nitrate in the first catalyst is 18:1;

[0133] 2) Preparation of the second catalyst

[0134] Sodium carbonate, nickel nitrate, and cerium nitrate are mechanically mixed to obtain a second catalyst, and the molar ratio between sodium carbonate, nickel nitrate and cerium nitrate in the second catalyst is 18:12:1;

[0135] 3) Preparation of copper-zinc-aluminum-rare earth composite catalyst

[0136] 181.2kg copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 91.8kg zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 52.9 aluminum nitrate (Al(NO 3 ) 3 9H 2O) be dissolved in distilled water, make mixed nitrate solution; Under room temperature and stirring condition, mix nitrate solution and the sodium carbonate solution of 1mol / L and flow drop in the container that distilled wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com