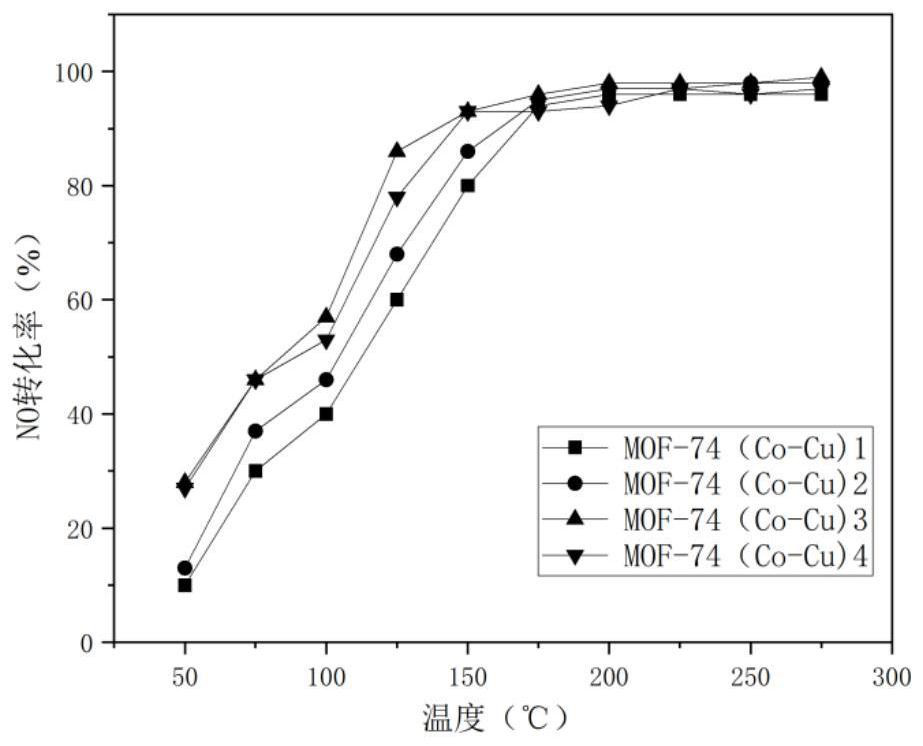

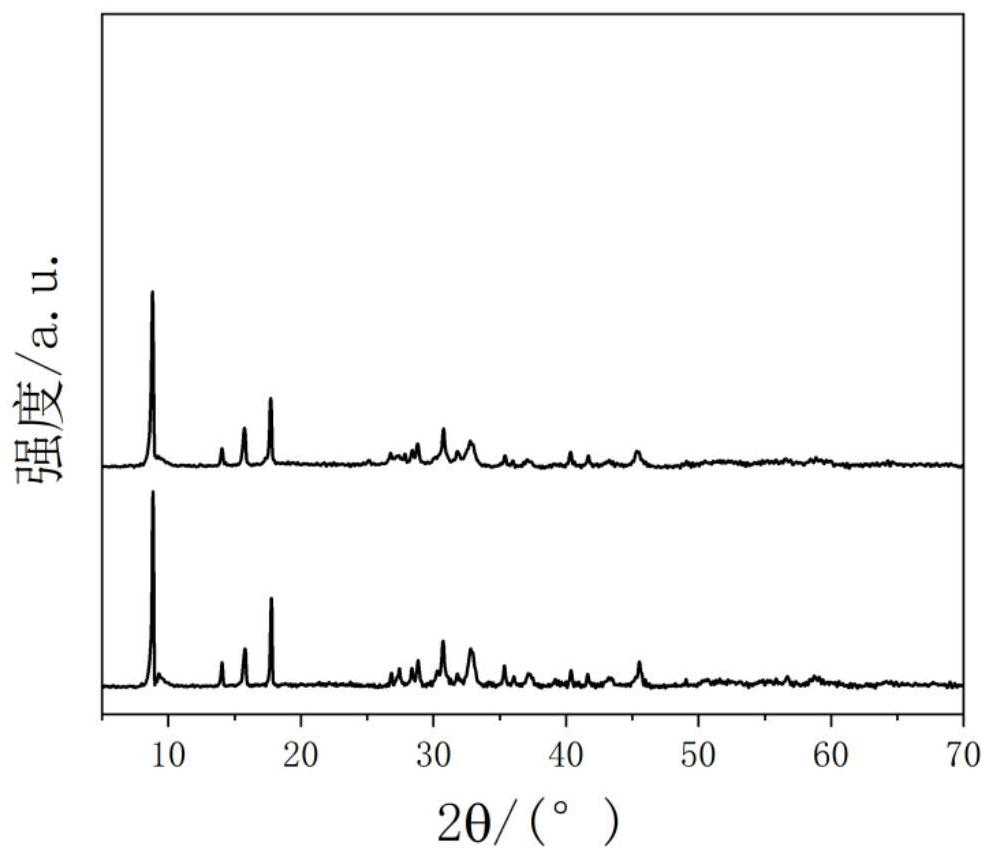

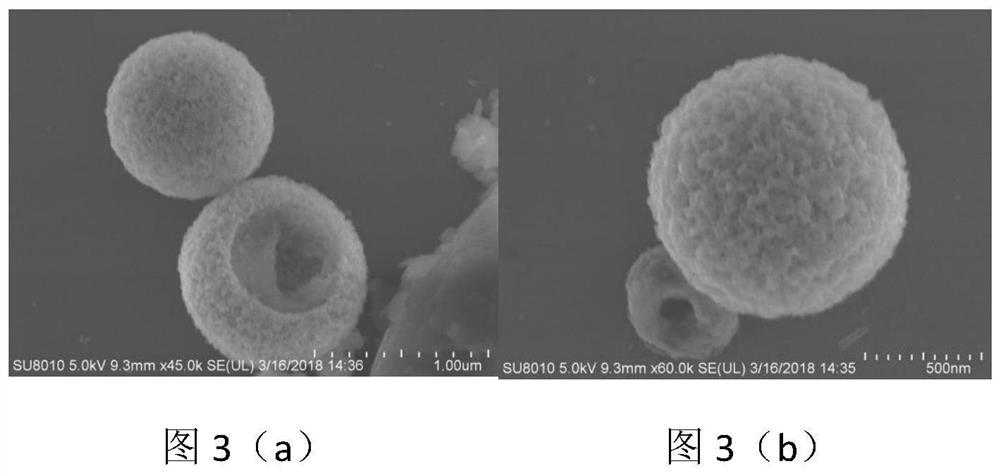

Preparation method and denitration application of bimetal MOF-74(Co-Cu) with meso-scale regulation and control multi-level core-shell structure

A technology of MOF-74 and core-shell structure, which is applied in the field of preparation of multi-level core-shell structure MOF-74 materials, can solve the difficulty in the synthesis of bimetallic MOFs materials, which affects the synthesis rate of Co precursors, the reduction of surface area and active sites and other problems, to achieve the effect of high catalytic activity, good catalyst dispersion and regular pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing mesoscale-controlled multi-level core-shell bimetallic MOF-74 (Co-Cu) specifically includes the following steps:

[0042] (1) Preparation of Co precursor: Dissolve 244mg of 2,5-dihydroxyterephthalic acid in a total volume of 90mL with a volume ratio of (6:3:1) N-2-methylpyrrolidone-isopropanol-ultrapure water In the mixed system, solution A was obtained; 865 mg [5,10,15,20-tetrakis (4-methoxyphenyl) porphyrin] cobalt (II) and 128 mg sodium dodecyl diphenyl ether disulfonate were dissolved In the above solution A, sonicate for 25 minutes, wherein the frequency of ultrasonic treatment is 60KHz, and the power is 180W, to obtain solution B; transfer the above solution B to a 100mL polytetrafluoroethylene reactor, and react at a reaction temperature of 125°C for 4 hours to obtain The suspension of the surface-modified Co precursor was centrifuged at 8000r / min for 24min in a centrifuge, washed three times with N-2-methylpyrrolidone and ultrapure water a...

Embodiment 2

[0047] A method for preparing mesoscale-controlled multi-level core-shell bimetallic MOF-74 (Co-Cu) specifically includes the following steps:

[0048] (1) Preparation of Co precursor: Dissolve 232mg of 2,5-dihydroxyterephthalic acid in a total volume of 80mL with a volume ratio of (6:2:1) N-2-methylpyrrolidone-isopropanol-ultrapure water In the mixed system, solution A was obtained; 576mg [5,10,15,20-tetrakis(4-methoxyphenyl) porphyrin]cobalt(II) and 132mg sodium dodecyl diphenyl ether disulfonate were dissolved In the above solution A, sonicate for 32 minutes, wherein the frequency of ultrasonic treatment is 60KHz, and the power is 180W, to obtain solution B; transfer the above solution B to a 100mL polytetrafluoroethylene reactor, and react at a reaction temperature of 100°C for 4 hours to obtain The suspension of the surface-modified Co precursor was centrifuged at 8000r / min for 24min in a centrifuge, washed three times with N-2-methylpyrrolidone and ultrapure water and dr...

Embodiment 3

[0053] A method for preparing mesoscale-controlled multi-level core-shell bimetallic MOF-74 (Co-Cu) specifically includes the following steps:

[0054](1) Preparation of Co precursor: Dissolve 252mg of 2,5-dihydroxyterephthalic acid in a total volume of 100mL with a volume ratio of (6:3:1) N-2-methylpyrrolidone-isopropanol-ultrapure water In the mixed system, solution A was obtained; 934 mg [5,10,15,20-tetrakis (4-methoxyphenyl) porphyrin] cobalt (II) and 31 mg sodium dodecyl diphenyl ether disulfonate were dissolved In the above solution A, sonicate for 32 minutes, wherein the frequency of ultrasonic treatment is 60KHz, and the power is 180W, to obtain solution B; transfer the above solution B to a 100mL polytetrafluoroethylene reactor, and react at a reaction temperature of 135°C for 6 hours to obtain The suspension of the surface-modified Co precursor was centrifuged at 8000r / min for 30min in a centrifuge, washed three times with N-2-methylpyrrolidone and ultrapure water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com