A kind of use of cyanobacteria and algae mud of algae water separation station to prepare biomass activated carbon and use it for the adsorption of algal toxins in tail water

A technology of activated carbon adsorption and algae water separation, which is applied in the field of resources and environment, can solve problems such as health hazards of residents in the surrounding ecological environment, and achieve the effects of good adsorption selectivity, good application prospects and uniform appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

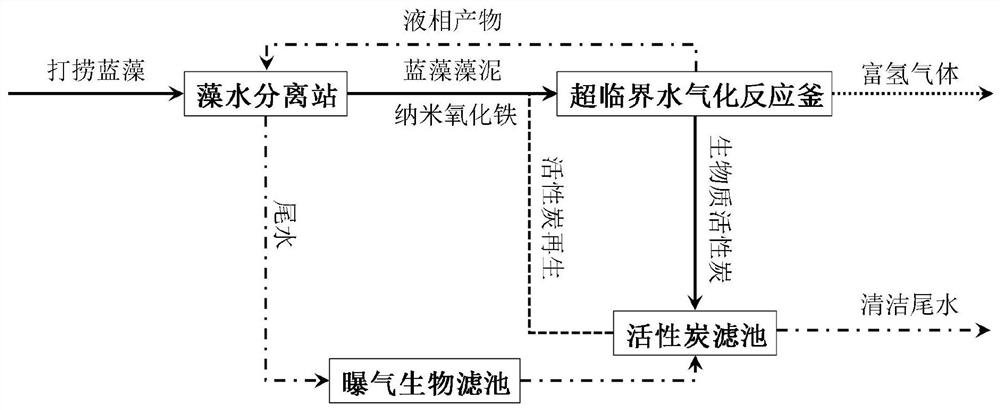

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of nano iron oxide

[0023] Under the stirring state of rotating speed, weigh 0.015g (0.0004mol) sodium tripolyphosphate and 0.074g (0.00042mol) potassium sulfate solution and add 0.432g (0.002mol) iron trichloride hexahydrate, after fully dissolving, add 3.6g ( 0.060mol) urea, control the pH value to 10, and obtain the precursor solution; then transfer 80mL of the above mixed solution to a 100mL hydrothermal reaction kettle, and after hydrothermal reaction at 180°C for 25h, the reaction is completed to obtain a brick red precipitate, which is cooled and centrifuged , washing and drying to obtain nanometer iron oxide.

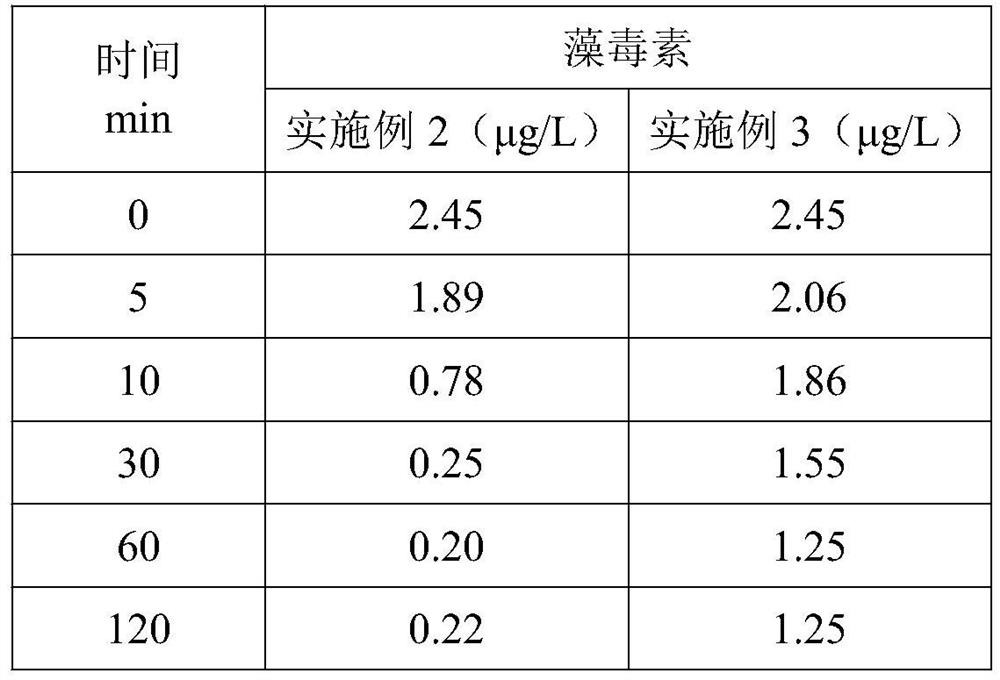

Embodiment 2

[0024] Embodiment 2: preparation of biomass activated carbon, the additive is the nano iron oxide prepared in embodiment 1

[0025] Step S1, uniformly dispersing the nano-ferric oxide in the cyanobacteria-algae mud produced by the algae-water separation station to obtain the algae mud to be treated, the moisture content of the algae mud is controlled at 90.5%, and the addition ratio of nano-iron oxide to the algae mud is 2wt%;

[0026] Step S2, the algae mud to be treated is transported to the continuous supercritical water gasification reactor through a high-pressure plunger pump, and the supercritical water gasification reaction is carried out at a rate of 15 °C / min to 450 °C and 22.5 MPa for 10 minutes, and the reaction Fe(III)-biomass activated carbon was obtained after the product was cooled, gas-liquid-solid separation, solvent washing and drying.

Embodiment 3

[0027] Example 3: Preparation of Biomass Activated Carbon, Without Adding Nano Iron Oxide

[0028] Step S1, controlling the moisture content of the cyanobacteria algae mud produced by the algae water separation station to 90.5%

[0029] Step S2, the algae mud to be treated is transported to the continuous supercritical water gasification reactor through a high-pressure plunger pump, and the supercritical water gasification reaction is carried out at a rate of 15 °C / min to 450 °C and 22.5 MPa for 10 minutes, and the reaction The product is cooled, gas-liquid-solid separation, solvent cleaning, and drying to obtain biomass activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com