Process for preparing high dispersivity square blocky superfine magnesium hydroxide by one-step method

A high-dispersion, magnesium hydroxide technology, applied in the direction of magnesium hydroxide, etc., can solve the problems of reduced processing performance and product quality, poor compatibility with high polymers, and uneven particle size distribution, achieving narrow and uniform distribution range Dispersion, the effect that the equipment is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

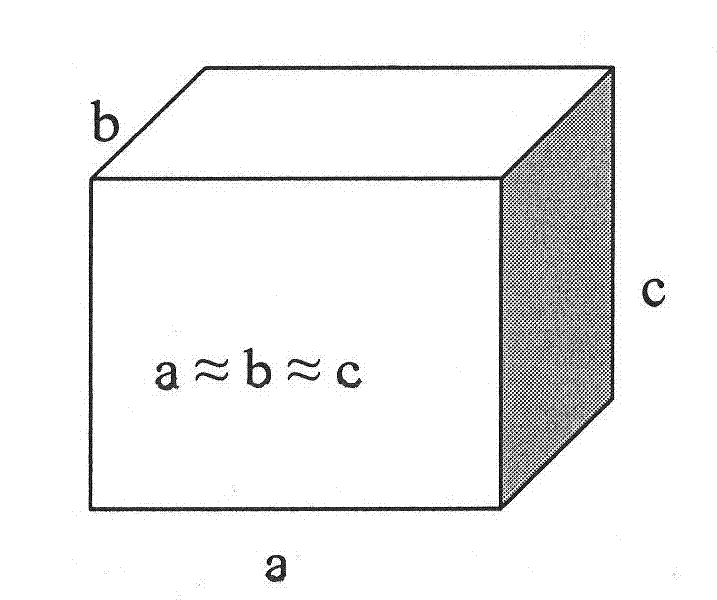

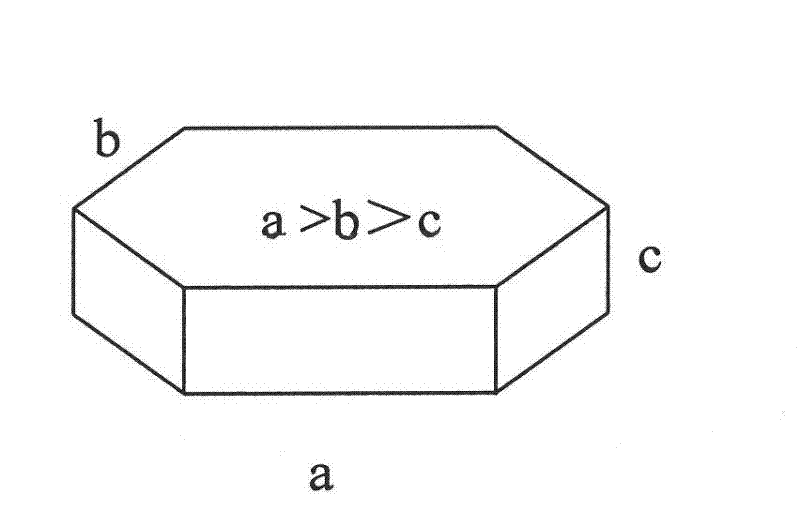

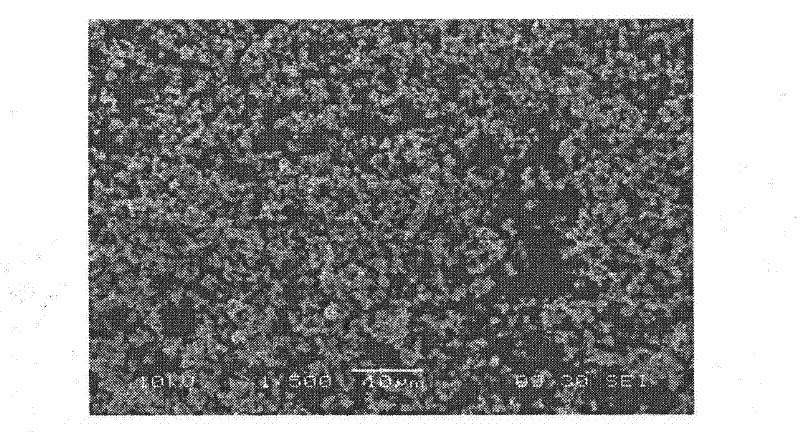

[0030] Prepare a 1.0mol / L refined magnesium chloride solution, take 500mL of this solution and add it to a bubbling reactor with a volume of 2000mL, stir the solution in the reactor and control its temperature at 70°C, and directly pass ammonia gas into the reaction in the form of bubbling The solution was subjected to magnesium precipitation reaction, the flow rate of ammonia gas was 0.20g / min, the pH value of the reaction solution was about 9.5 at 70°C for 2 hours at a constant temperature, and a milky white suspension of magnesium hydroxide and ammonium salt was obtained. The product solution was aged at a constant temperature of 70°C for 2 hours, and the aged product solution was vacuum filtered. The filter cake was washed with deionized water for 3 times and then vacuum-dried at 80°C for 12 hours to obtain loose tetragonal fine hydrogen Magnesium oxide powder. The filtrate is returned to the ammonia distillation device, and an appropriate amount of magnesium source is sup...

Embodiment 2

[0032] Prepare 2.0mol / L refined magnesium chloride solution, take 500mL of this solution and add it to a bubbling reactor with a volume of 2000mL, stir the solution in the reactor and control its temperature at 90°C, and directly pass ammonia gas into the reaction in the form of bubbling The solution was subjected to magnesium precipitation reaction, the flow rate of ammonia gas was 0.50g / min, and the pH value of the reaction solution was about 9.5 at a constant temperature of 90°C for 3 hours to obtain a milky white suspension of magnesium hydroxide and ammonium salt. The product solution was aged at 70°C for 1 hour, vacuum filtered the aged product solution, and the filter cake was washed with deionized water for 3 times and then vacuum-dried at 80°C for 12 hours to obtain loose tetragonal fine hydrogen Magnesium oxide powder, particle average diameter D 50 About 0.7μm, the largest particle size (secondary particle) is less than 5.0μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com