Method for synthesizing hydrotalcite like compound nano particles by room temperature solid phase method

A nanoparticle, room temperature solid phase technology, applied in nanotechnology, oxide/hydroxide preparation and other directions, can solve the problems of uneven agglomeration of crystal forms of hydrotalcite-like products, achieve good monodispersity, simple operation process, Reliable effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Adopt the inventive method to synthesize Mg 3 -Al-CO 3 - LDH nanoparticles, comprising the steps of:

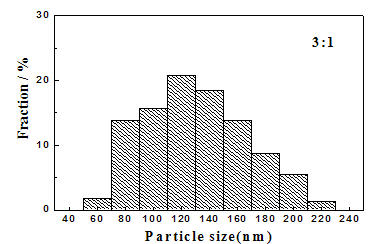

[0035] (1) At room temperature, the Mg(NO 3 ) 2 ?6H 2 O, Al(NO 3 ) 3 ?9H 2 O, Na 2 CO 3 Pre-grind with NaOH for 2min, then weigh 0.7692g Mg(NO 3 ) 2 ?6H 2 O and 0.3751g Al(NO 3 ) 3 ?9H 2 O (the molar ratio of substances is 3:1), add to contain 0.0596g Na 2 CO 3In a mortar mixed with 0.36g NaOH (Na 2 CO 3 The molar ratio of NaOH to NaOH is 1:16), manually grind at a constant speed for 30-100min, until the mixture is dry. Centrifuge and wash with distilled water for 3 to 4 times to obtain the nano-LDH precursor.

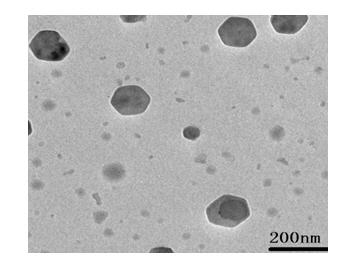

[0036] (2) Disperse the precursor in 20ml double-distilled water, put it in an oven, and peptize it at 80°C for 20 hours, and then get Mg with regular shape and good dispersion 3 -Al-CO 3 - LDH Serum.

[0037] (3) Mg 3 -Al-CO 3 -LDH slurry is vacuum dried to obtain Mg 3 -Al-CO 3 - LDH nanomaterials.

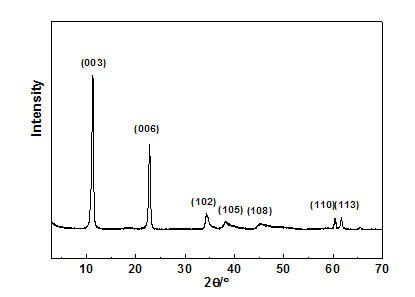

[0038] The resulting Mg 3 -Al-CO...

Embodiment 2

[0041] Synthesize Mg according to the method identical with embodiment 1 2 -Al-CO 3 -LDH nanoparticles, changing Mg(NO 3 ) 2 ?6H 2 O and Al(NO 3 ) 3 ?9H 2 The substance ratio of O is 2:1, and other conditions remain unchanged, and Mg is synthesized 2 -Al-CO 3 - LDH nanoparticles.

[0042] Mg 2 -Al-CO 3 -The TEM image of LDH nanoparticles and the particle size distribution of nanoparticles are shown in Figure 4 , Figure 5 As shown, the results show that the obtained Mg 2 -Al-CO 3 -LDH nanoparticles still maintain good dispersion and regular morphology.

Embodiment 3

[0044] Synthesize Mg according to the method identical with embodiment 1 4 -Al-CO 3 -LDH nanoparticles, changing Mg(NO 3 ) 2 ?6H 2 O and Al(NO 3 ) 3 ?9H 2 The substance ratio of O is 4:1, and other conditions remain unchanged, and Mg is synthesized 4 -Al-CO 3 - LDH nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com