Method and device for continuously and stably preparing acesulfame potassium crystal

A kind of acesulfame potassium and stable technology, which is applied in the field of preparing acesulfame potassium crystals, can solve the problems of long crystallization time, many equipment crossings, unstable quality, etc., and achieve the effect of high degree of industrialization and uniform crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

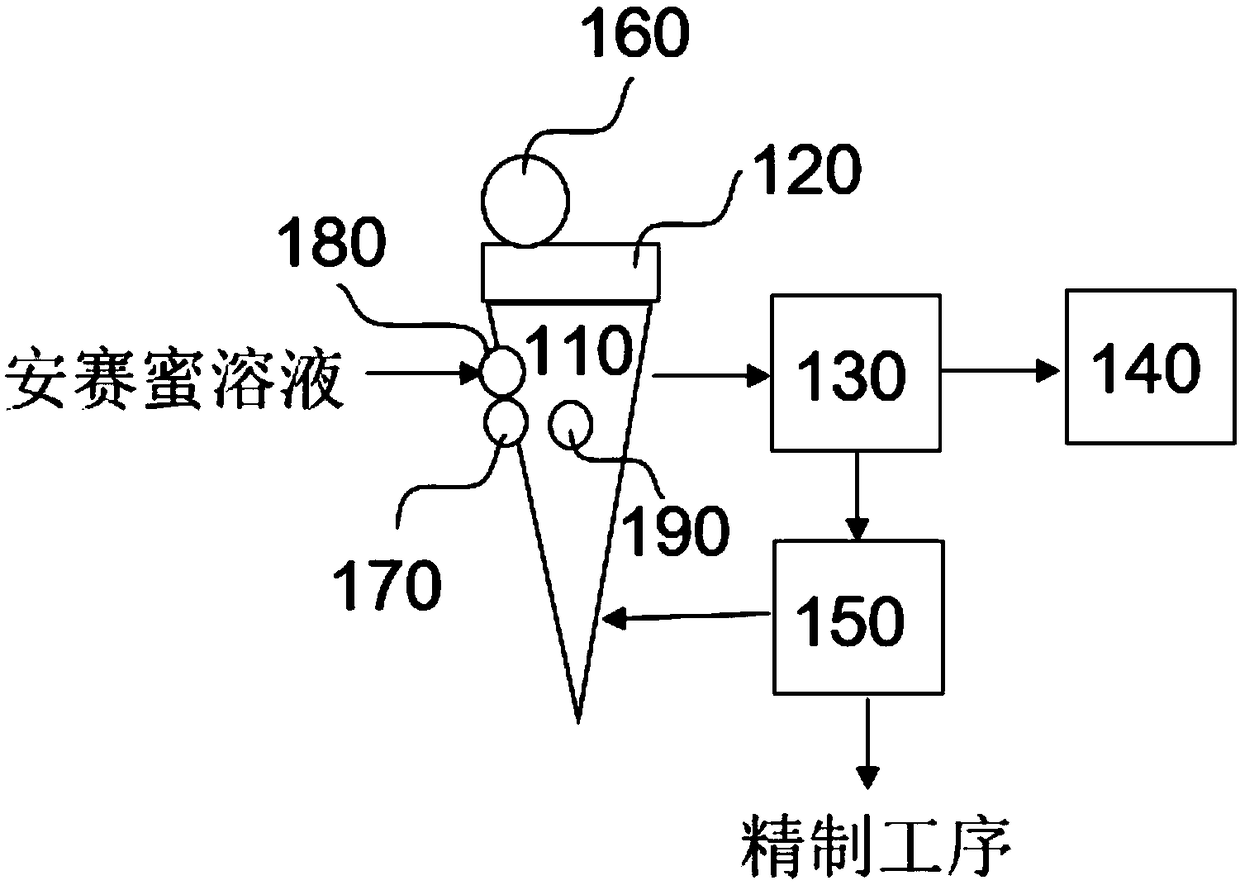

[0028] The acesulfame potassium solution enters the decompression evaporator from the feed pipe, and forms a circulation under the action of the heat exchanger. The temperature of the acesulfame potassium solution is controlled at 80°C, and the flow control valve of the heating medium of the heat exchanger is adjusted by the temperature controller. The moisture in the material is evaporated and removed under vacuum, and the vacuum degree is controlled at -0.075MPa. The level gauge signal in the reduced pressure evaporator controls the feed valve. Set a liquid online density real-time monitor at 2 / 3 of the bottom of the cone in the decompression evaporator, and the density is 1.25g / cm 3 At this time, the signal is sent to the delivery pump motor to start, and the collected concentrated liquid is sent to the crystallization tank. The crystallization tank is composed of agitator, external circulation pump and cooler. The crystallization temperature of the material in the crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com