Adsorbent for removing chromate ions from water, and preparation method thereof

A chromate and water removal technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problem of low chromate ion removal efficiency, etc., and achieve high dechromate efficiency and optimization. Removal efficiency, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

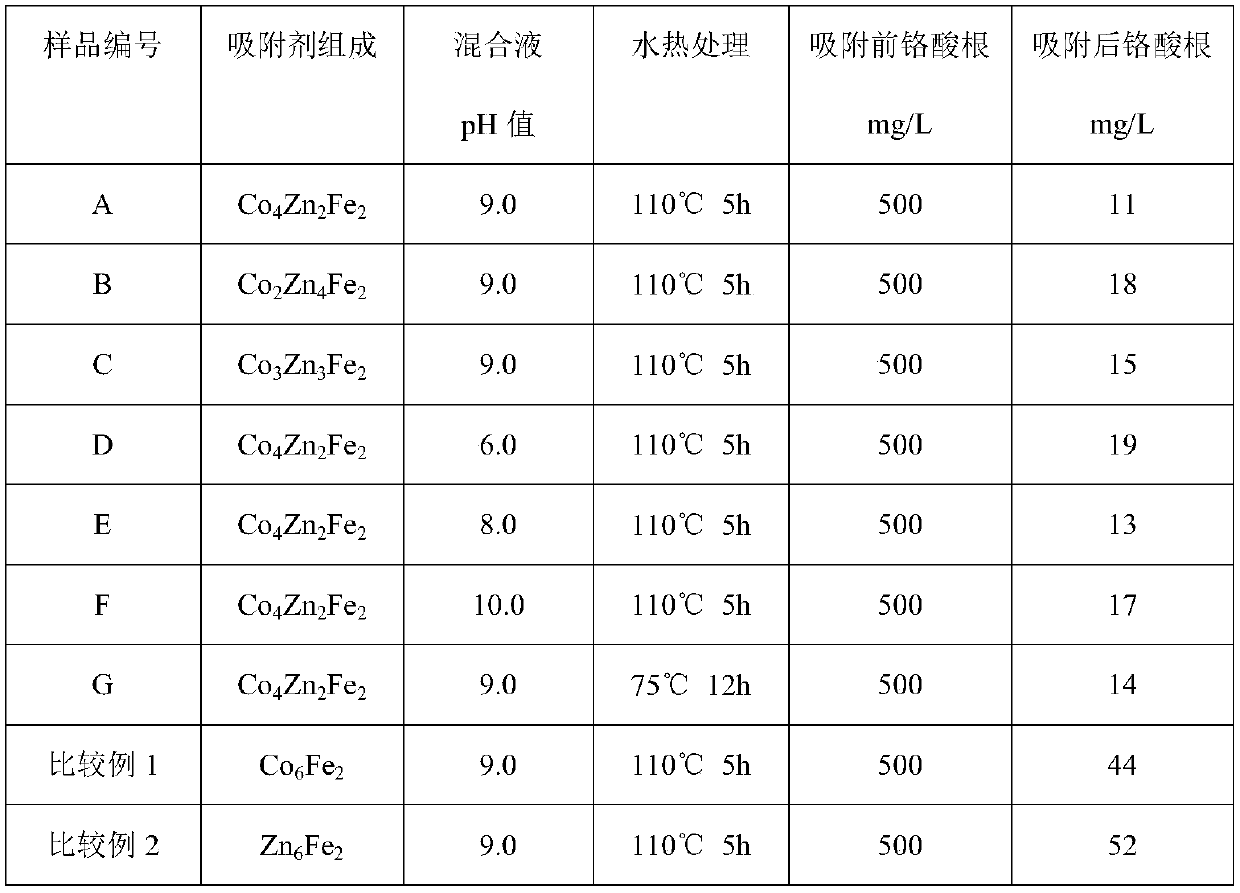

[0034] Dissolve cobalt nitrate, zinc nitrate and ferric nitrate in deionized water at a molar ratio of 4:2:2, stir at room temperature until clear, and record it as solution A; dissolve sodium hydroxide in deionized water, stir at room temperature until clear , recorded as solution B; quickly drop solution B into solution A, stop when the pH value of the solution reaches 9.0, continue to stir for 2 hours, pour the solution into a crystallization kettle and treat it with hydrothermal treatment at 110°C for 5 hours, filter, wash, and dry at 110 ℃ drying for 10h to obtain the adsorbent product A.

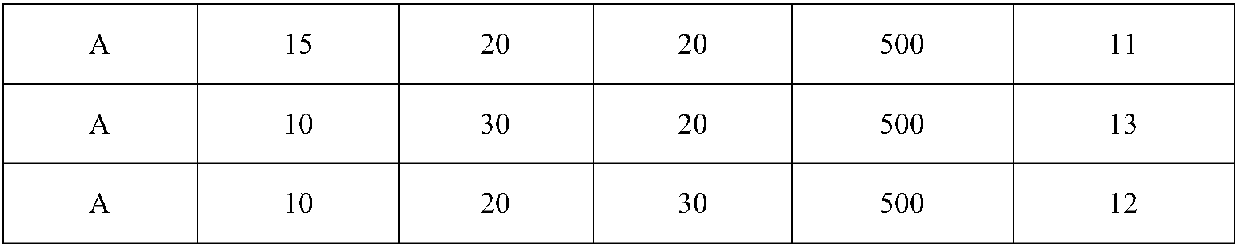

[0035] Add 10 g of adsorbent A to 1 L of aqueous solution containing 500 mg of chromate ions at 20° C., stir for 20 minutes and then detect the content of chromate ions in the water. The results are listed in Table 1.

Embodiment 2

[0037]Dissolve cobalt nitrate, zinc nitrate and ferric nitrate in deionized water at a molar ratio of 2:4:2, stir at room temperature until clear, and record it as solution A; dissolve sodium hydroxide in deionized water, stir at room temperature until clear , recorded as solution B; quickly drop solution B into solution A, stop when the pH value of the solution reaches 9.0, continue to stir for 2 hours, pour the solution into a crystallization kettle and treat it with hydrothermal treatment at 110°C for 5 hours, filter, wash, and dry at 110 ℃ drying for 10h to obtain the adsorbent product B.

[0038] Add 10 g of adsorbent B to 1 L of aqueous solution containing 500 mg of chromate ions at 20° C., stir for 20 minutes and then detect the content of chromate ions in the water. The results are listed in Table 1.

Embodiment 3

[0040] Dissolve cobalt nitrate, zinc nitrate and ferric nitrate in deionized water at a molar ratio of 3:3:2, stir at room temperature until clear, and record it as solution A; dissolve sodium hydroxide in deionized water, stir at room temperature until clear , recorded as solution B; quickly drop solution B into solution A, stop when the pH value of the solution reaches 9.0, continue to stir for 2 hours, pour the solution into a crystallization kettle and treat it with hydrothermal treatment at 110°C for 5 hours, filter, wash, and dry at 110 C and dried for 10 hours to obtain the adsorbent product C.

[0041] Add 10 g of Adsorbent C to 1 L of aqueous solution containing 500 mg of chromate ions at 20°C, stir for 20 minutes and then detect the content of chromate ions in the water. The results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com