Patents

Literature

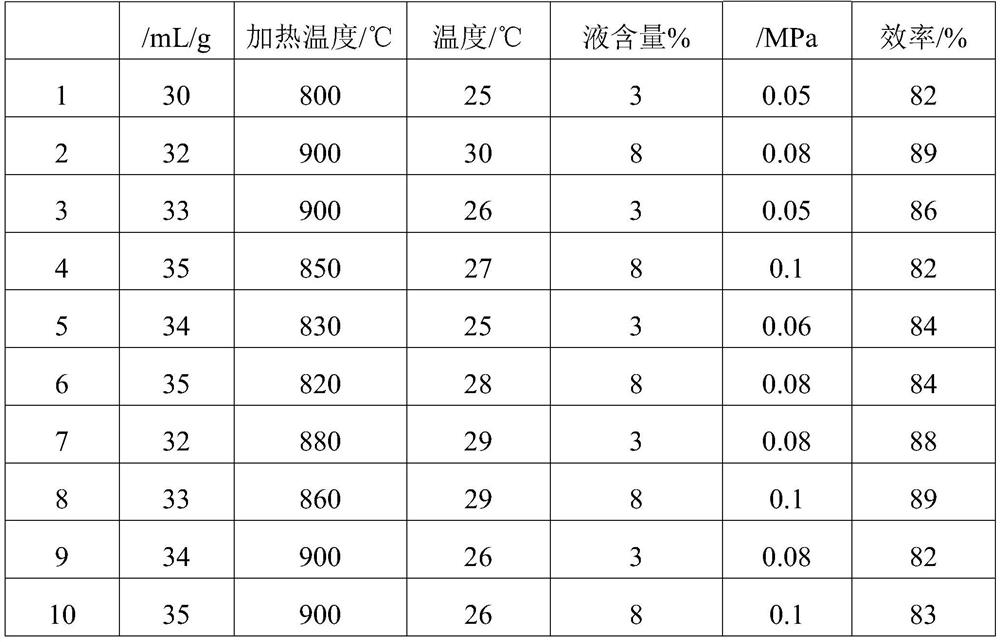

40results about How to "Reduce high temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

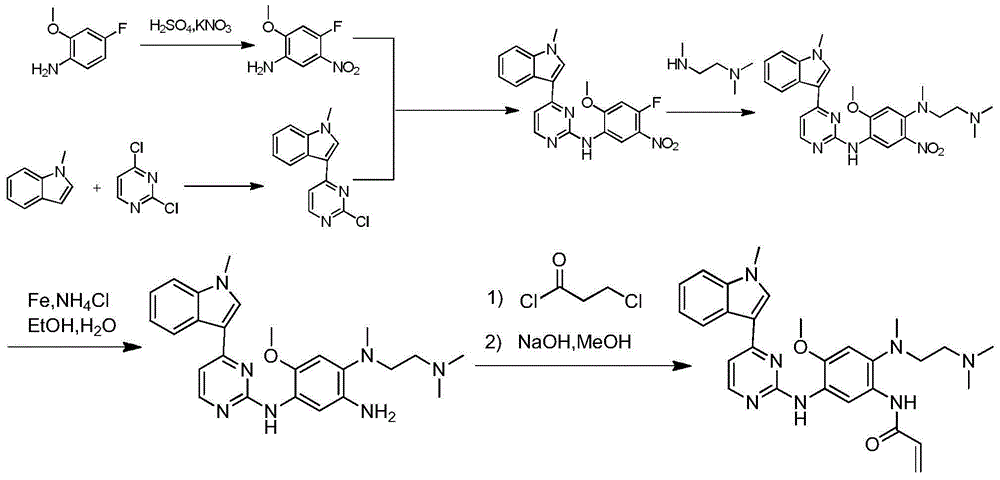

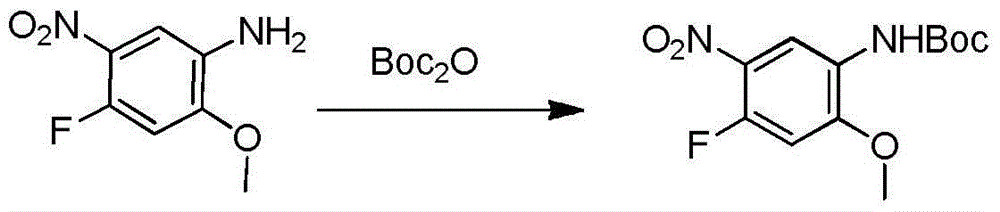

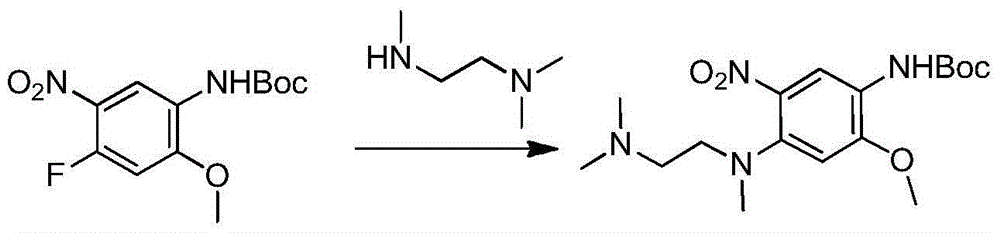

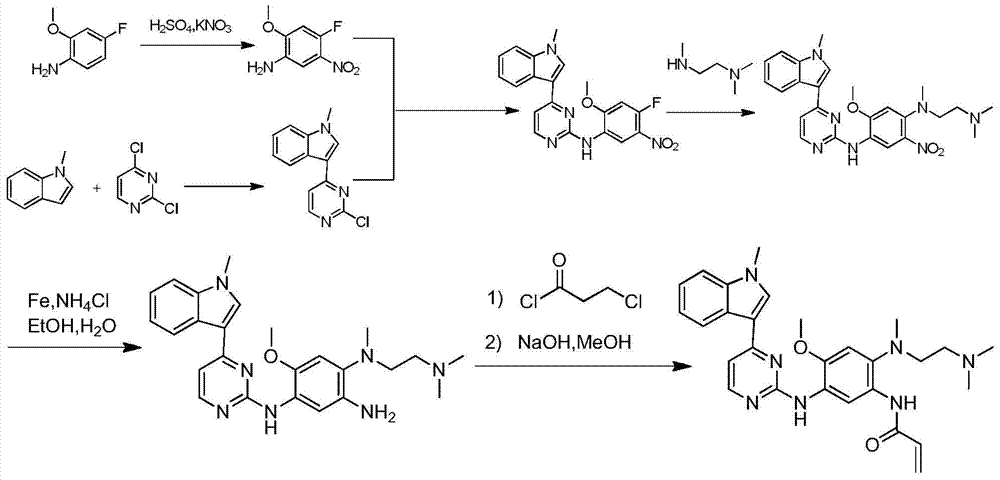

Synthetic method of anti-tumor medicine

ActiveCN104817541AHigh yieldMild reaction conditionsCarbamic acid derivatives preparationOrganic compound preparationCarbamateMethyl-1H-indole

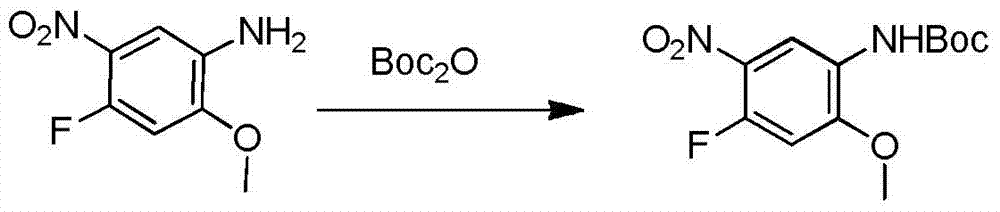

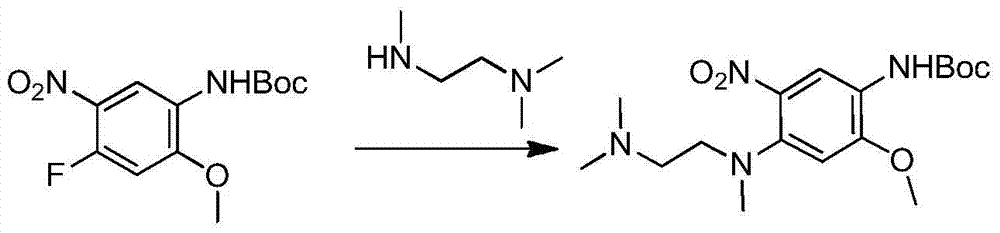

The invention relates to a synthetic method of an anti-tumor medicine, namely N-[2-[[2-(dimethylamino) ethyl] methyl amino]-4-methoxy-5-[[4-(1-methyl-1H-indole-3-yl)-2-pyrimidyl] amino] phenyl]-2-acrylamide (AZD9291) and a key intermediate of the anti-tumor medicine. The synthetic method comprises the following steps: performing Boc acid anhydride protection on 4-fluoro-2-methoxy-5-nitroaniline to obtain 4-fluoro-2-methoxy-5-nitroanilino tert-butyl formate, then reacting with N,N,N'-trimethylethylenediamine to obtain 4-(N,N,N'-trimethylethylenediamino)-2-methoxy-5-nitroanilino tert-butyl formate, then reducing to obtain 2-(N,N,N'-trimethylethylenediamino)-4-methoxy-5-tert-butyl carbamate phenylamine, then completely reacting with acryloyl chloride and directly removing a Boc protecting group to obtain 2-methoxy-4-N,N,N'-trimethylethylenediamino-5-acrylamido phenylamine, and finally reacting with 3-(2-chloropyrimidine-4-yl)-1-methylindole to obtain AZD9291. A process disclosed by the invention is simple in step, relatively high in yield, mild in reaction condition and easy for realization of industrial production.

Owner:苏州东南药业股份有限公司

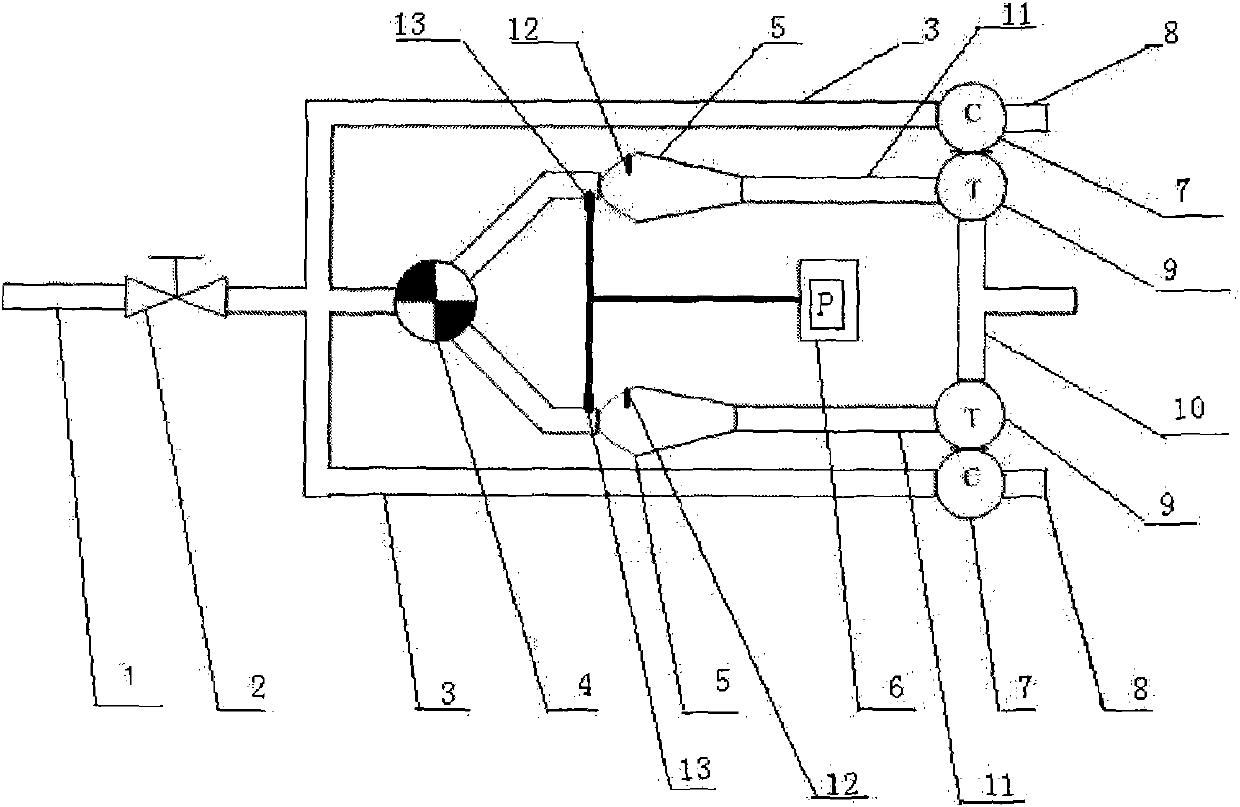

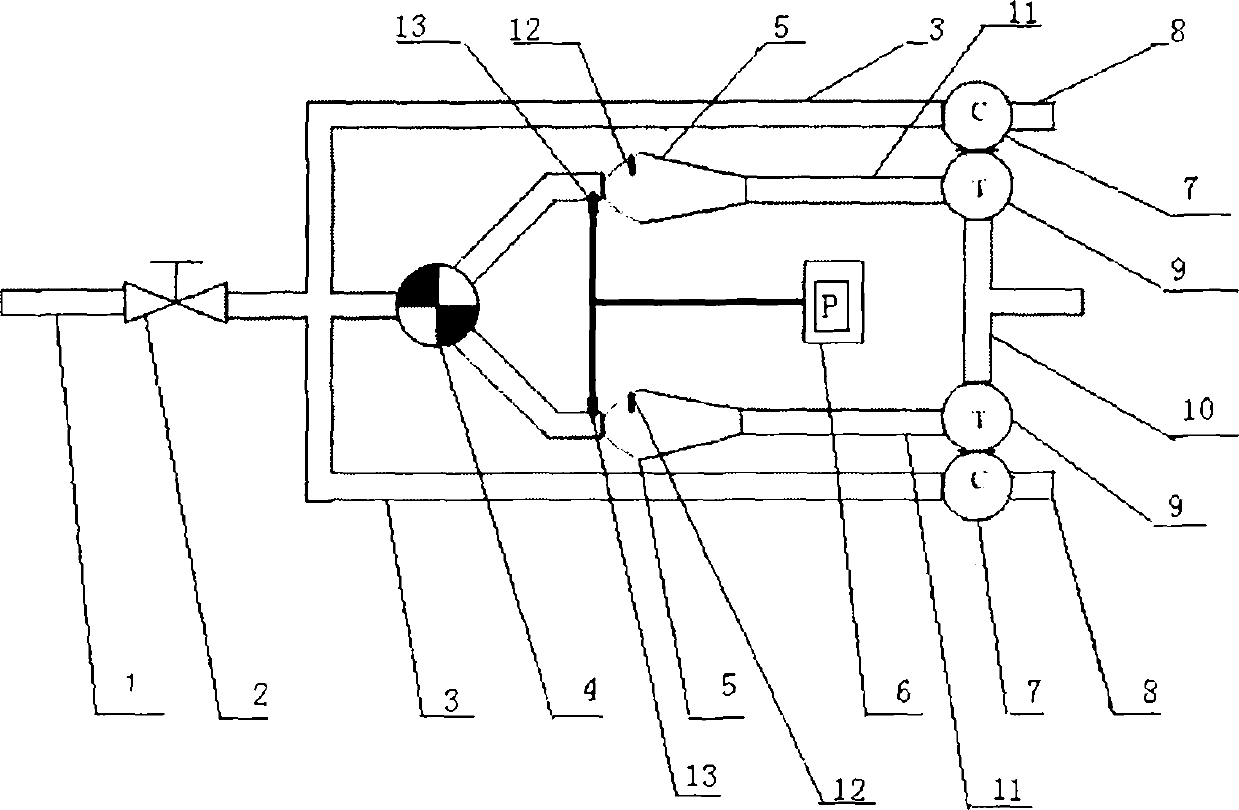

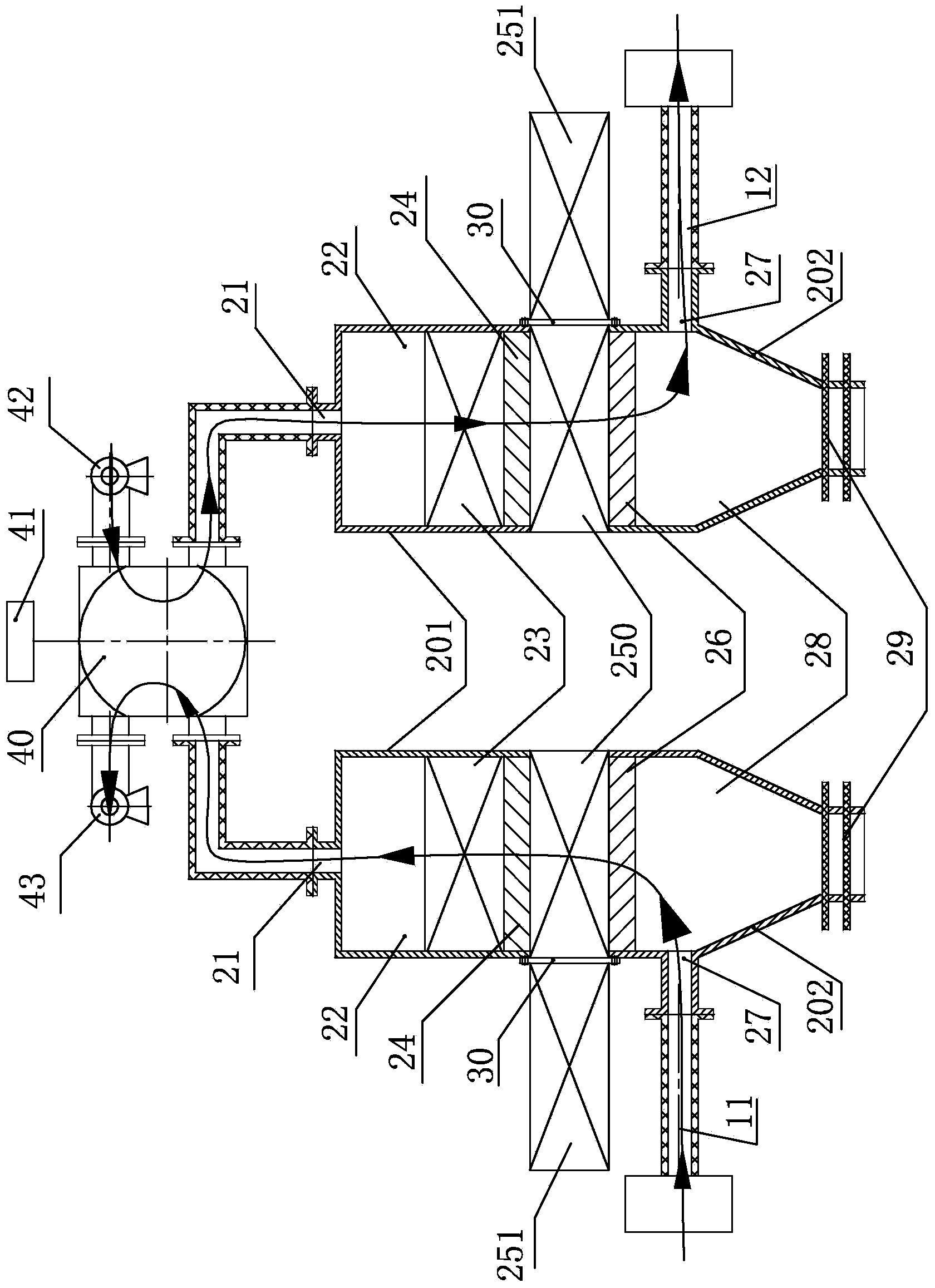

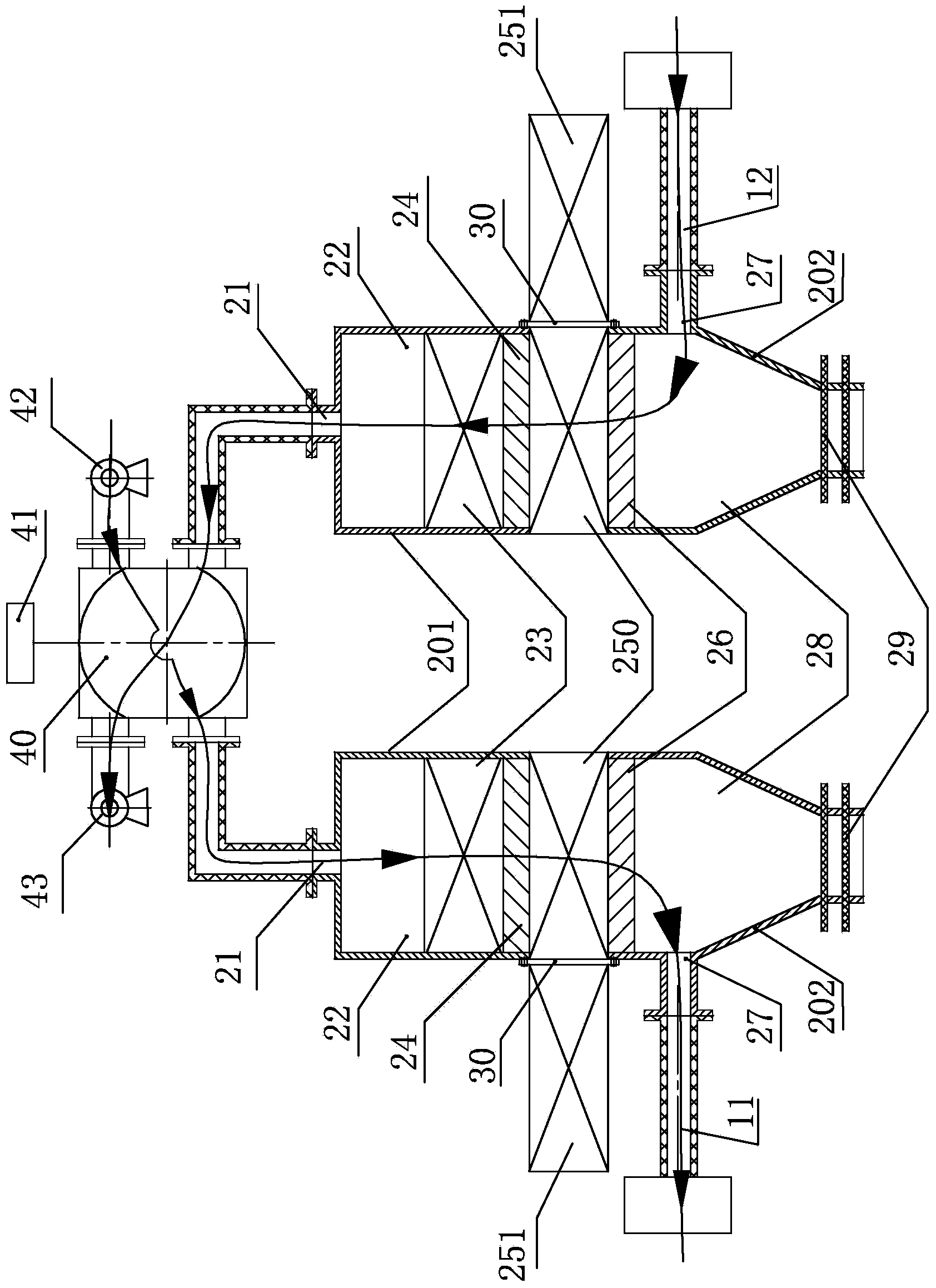

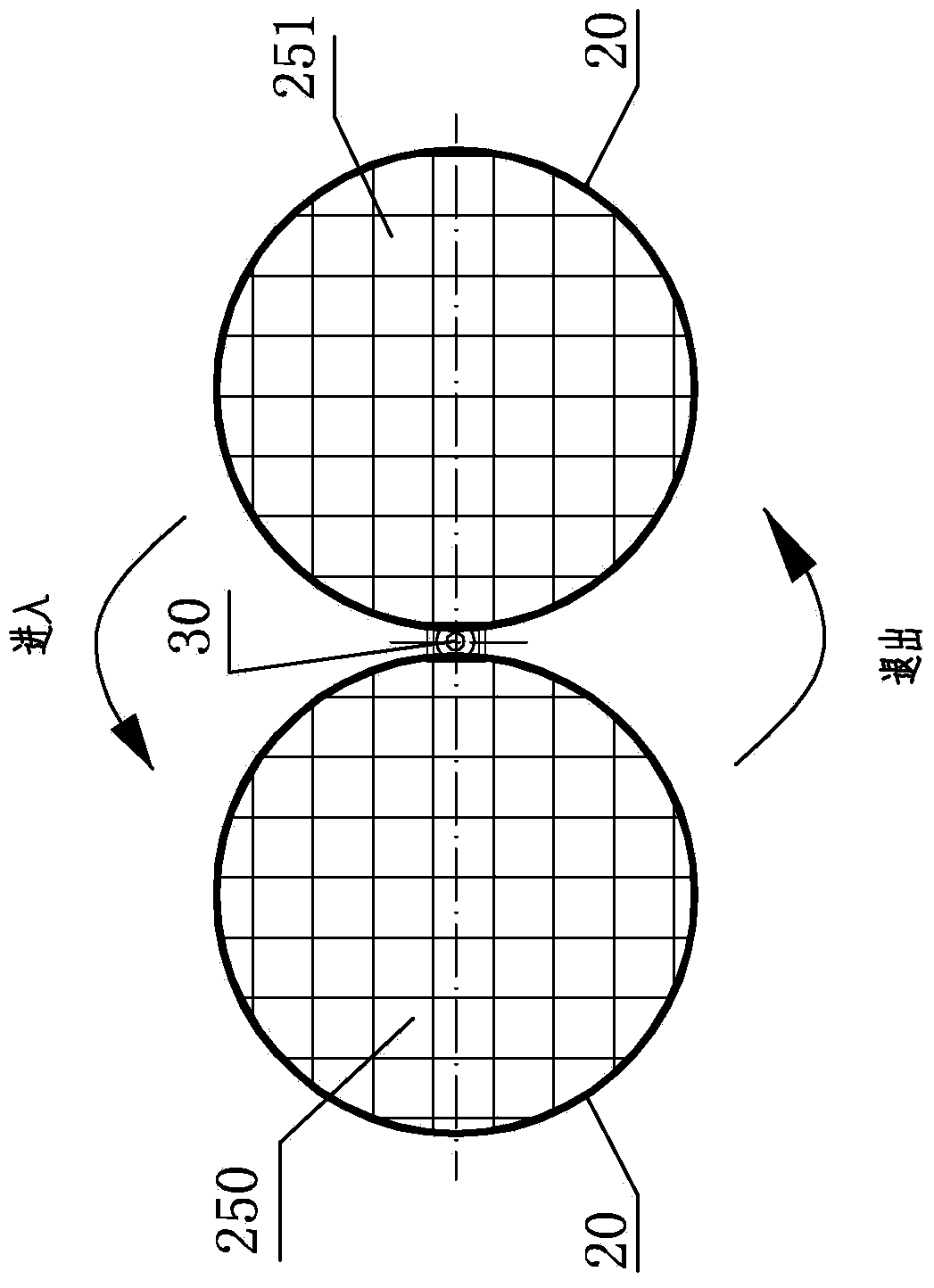

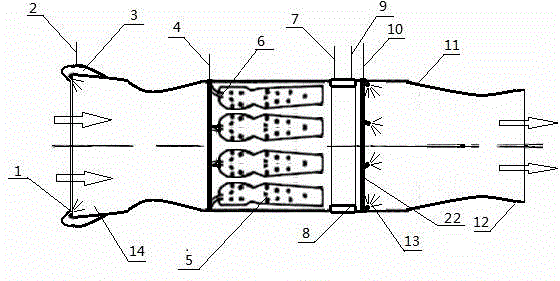

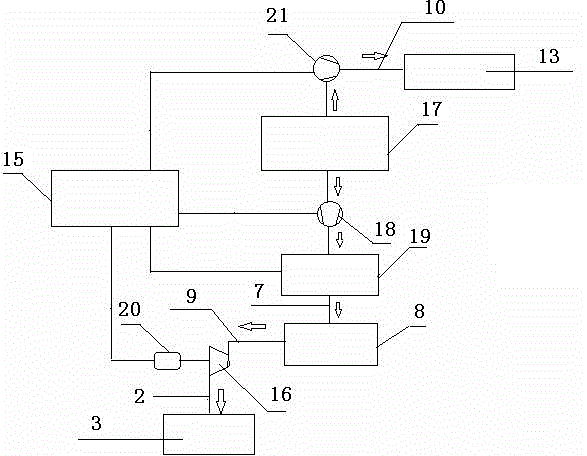

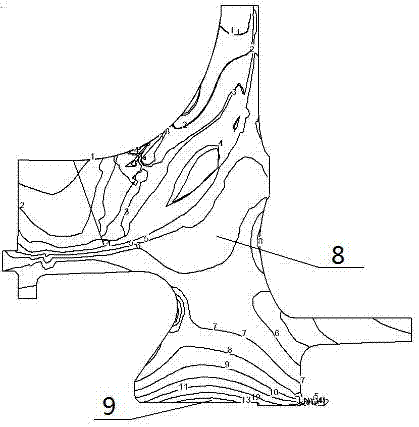

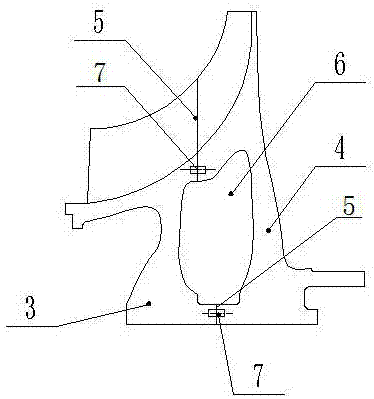

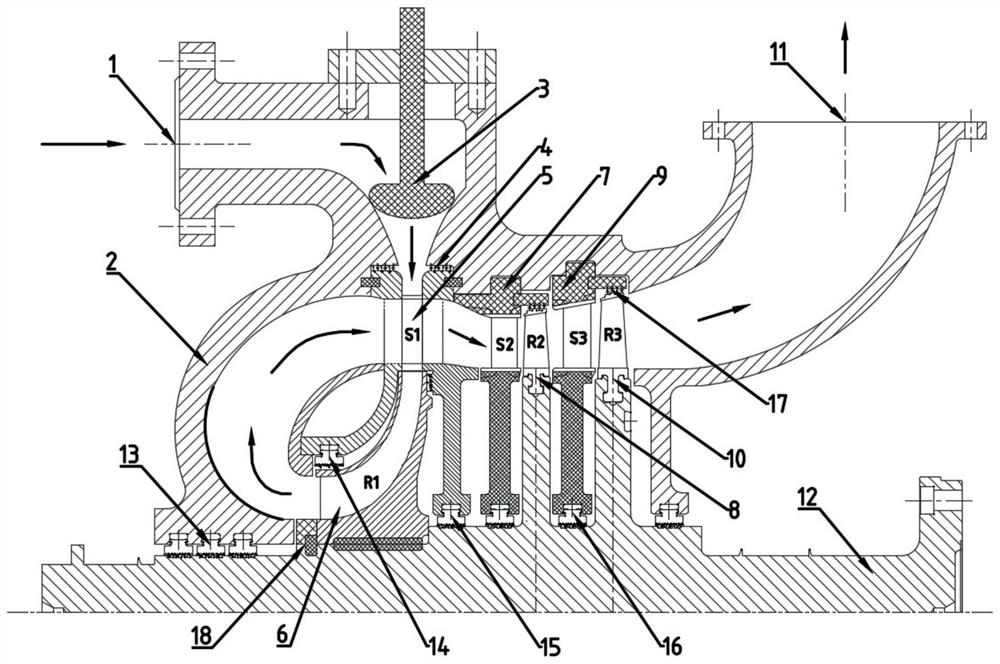

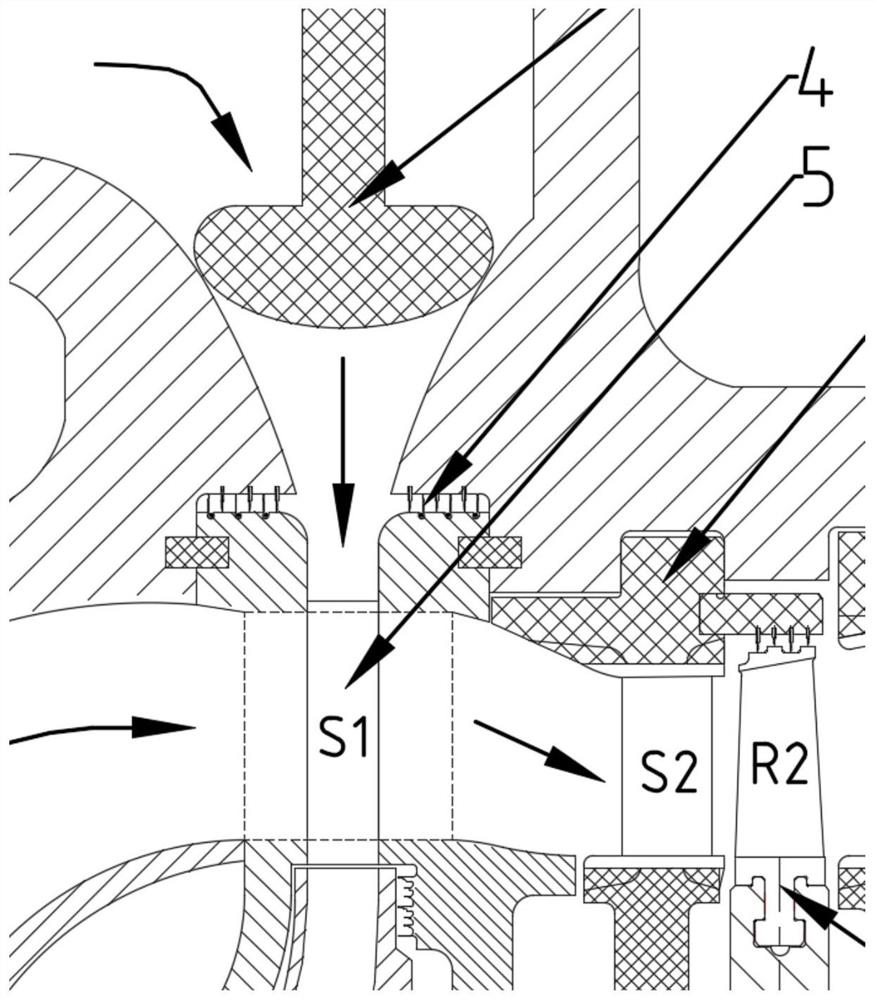

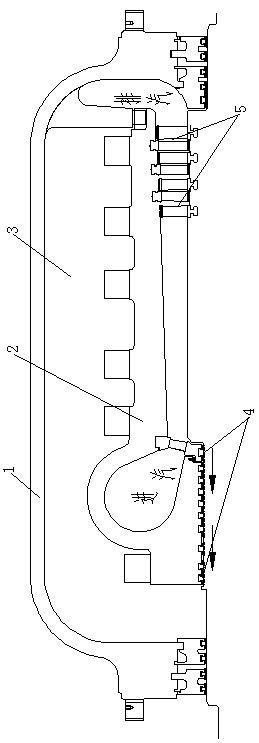

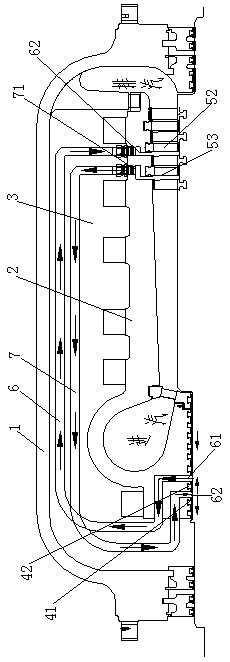

Test bench with double combustion chambers, double superchargers and low cycle fatigue based on self-circulation mode

InactiveCN101793619AReduce dependenceReduce consumptionInternal-combustion engine testingCombustion chamberPrice ratio

The invention relates to a test bench with double combustion chambers, double superchargers and low cycle fatigue based on a self-circulation mode, belonging to the technical field of power machinery. When the test bench with superchargers and low cycle fatigue which adopts a self-circulation principle is started and works, an external gas source firstly supplies gas to the combustion chambers and is closed after the superchargers stably runs, and a turbine and a compressor form self circulation, thereby reducing the dependency to power and the consumption of power, only needing fuel oil with a certain quantity and lowering the requirement of a low cycle fatigue test to compressed air and further reducing the requirement to an air compressor. In the test bench, air flows are respectively supplied to turbines of the two superchargers by adopting the two combustion chambers, and a measure that a flow distribution valve is installed before each combustion chamber enables the test bench with the double combustion chambers, the double superchargers and the low cycle fatigue to realize different gas inlet temperatures of each supercharger, thereby the mechanical load and the heat load needed by the low cycle fatigue test is changed, and the high temperature resistance requirements of materials of the flow distribution valve is reduced with high performance price ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

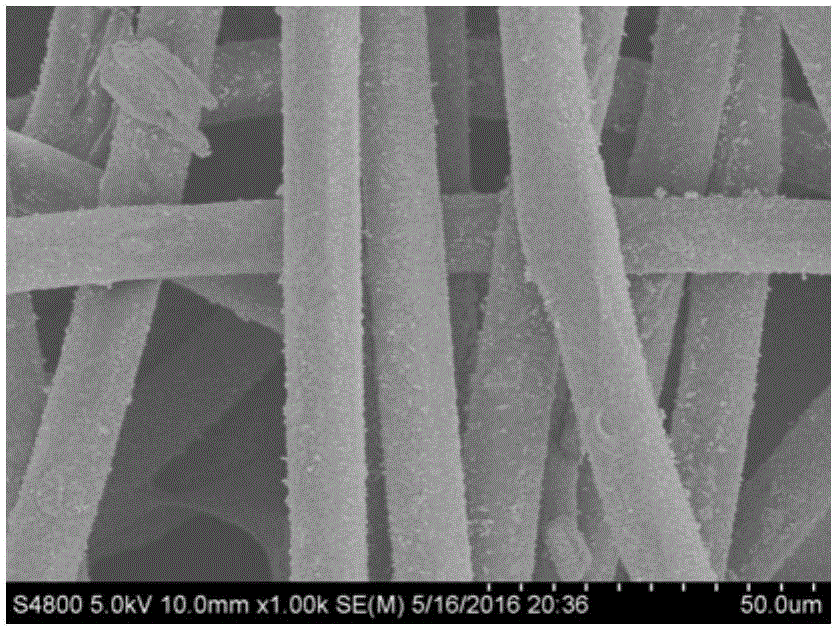

Method for growing titanium dioxide particles on base material

InactiveCN106311204AReduce high temperature requirementsWide selectionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrofluoric acidTithonia longiradiata

The invention discloses a method for growing titanium dioxide particles on a base material. The method includes the steps that 1, acid liquor and a titanium containing compound are mixed and stirred uniformly to obtain hydrothermal reaction liquid; 2, the base material is put in the hydrothermal reaction liquid, hydrothermal reaction is carried out at the temperature of 70-120 DEG C, and the titanium dioxide particles grow on the base material. The acid liquor is at least one of hydrochloric acid solution, nitric acid solution, sulfuric acid solution and hydrofluoric acid solution. The titanium containing compound is tetra-n-butyl titanate and / or isopropyl titanate. The size of the titanium containing compound accounts for 3-14% of the hydrothermal reaction liquid. The preparing method for growing the titanium dioxide particles on the base material is simple, the raw materials are easy to obtain, titanium dioxide firmly grows on the base material, and the crystal form and size of the titanium dioxide particles can be controlled to obtain high photocatalytic efficiency.

Owner:ZHEJIANG UNIV

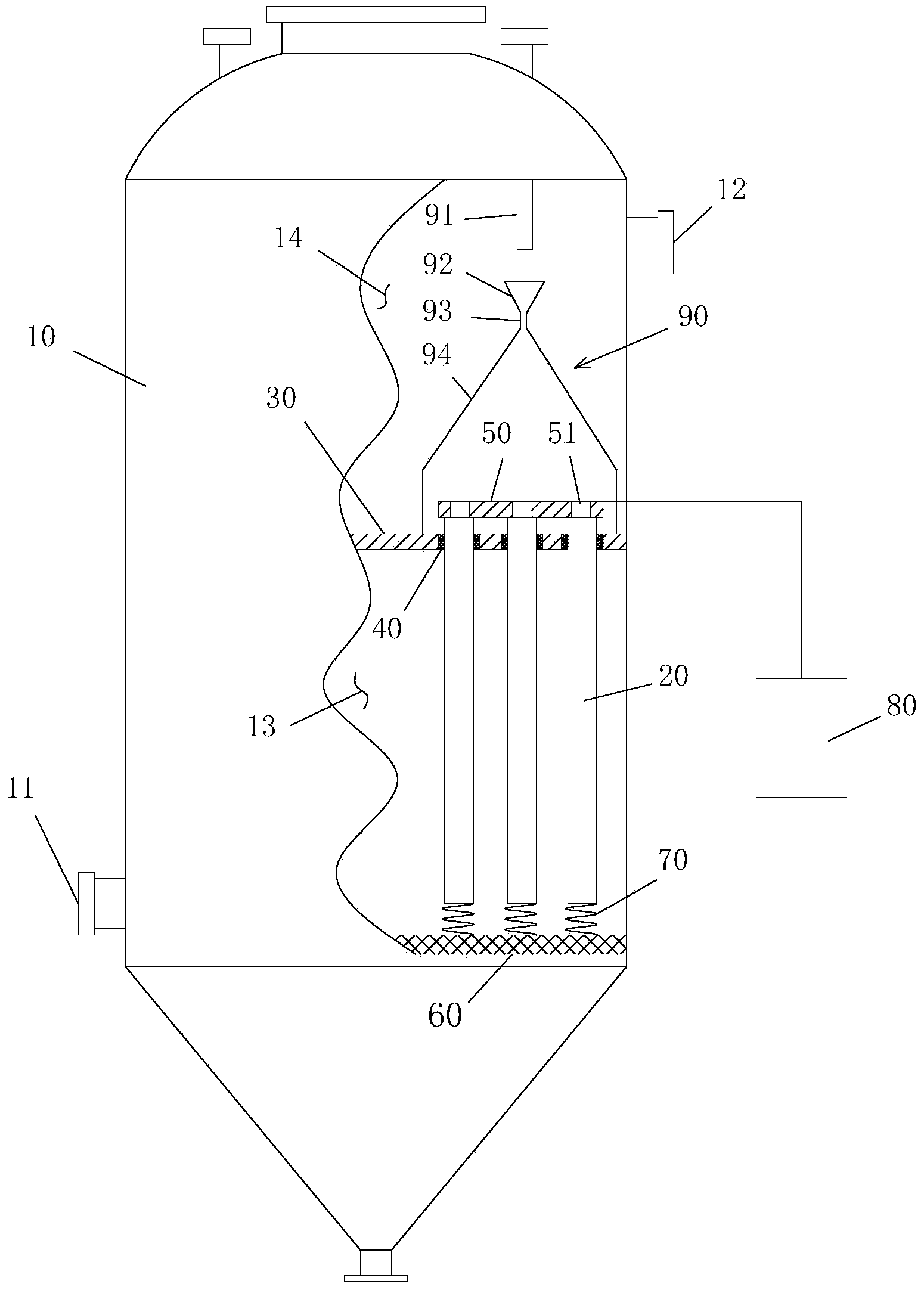

High-temperature flue gas waste heat recovery and dust extraction all-in-one device

ActiveCN103673643ALarge heat capacityModerate bulk densityDispersed particle filtrationCombustion processCombustionFiltration

The invention relates to a high-temperature flue gas waste heat recovery and dust extraction all-in-one device. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device comprises furnace connectors, material filtering beds, a left wind passing unit, a right wind passing unit and a four-way reversing valve, wherein the furnace connectors and the material filtering beds are connected with air flues on the two sides of a high-temperature kiln. Each wind passing unit comprises an upper wind opening, the corresponding low-temperature area material filtering bed, a low-temperature area frame, the corresponding high-temperature area material filtering bed, a high-temperature area frame, the corresponding furnace connector, a dust collection box and an ash outlet with movable partition plates from top to bottom. Each material filtering bed comprises accumulated ceramic balls. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device allows filtration and ash removing to be conducted in a mode that the leftward direction and the rightward direction are switched in a timed mode and filtration and ash removing are periodically and alternately conducted, and allows ash removing and heat absorption to be achieved in a mode that high-temperature flue gas from one side passes through the corresponding material filtering beds from bottom to top so that filtration and heat accumulation can be achieved, and air from the other side reversely blows the corresponding material filtering beds from top to bottom so that ash removing and heat absorption can be achieved. The ash-laden gas flue can be unceasingly filtered, waste heat in the high-temperature gas flue can be unceasingly recovered, meanwhile, function regeneration and fresh air preheating can be simultaneously conducted, cooling and dirt removing of the high-temperature flue gas are achieved, and combustion efficiency is improved.

Owner:宝武集团中南钢铁有限公司 +1

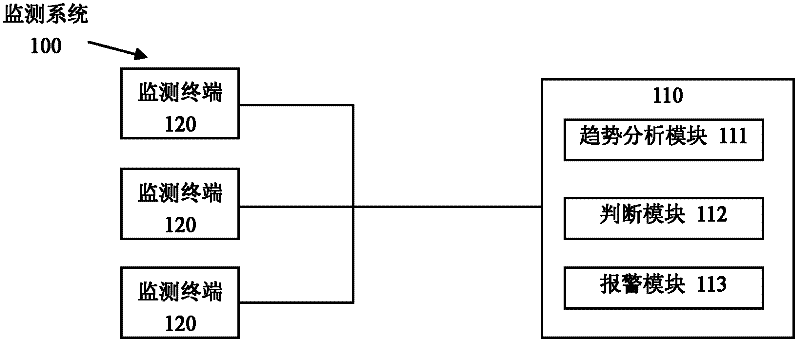

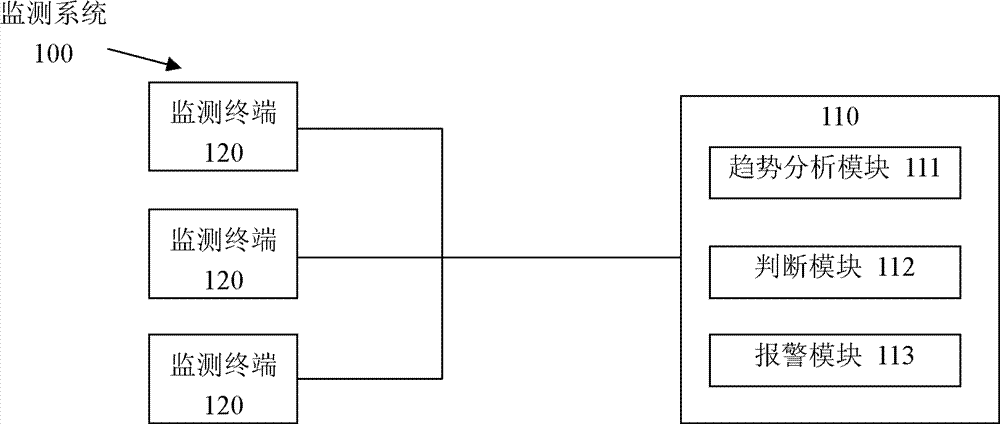

System for monitoring pressure vessel of reactor of nuclear power station and method thereof

ActiveCN102496393ALow costLow cost controlNuclear energy generationNuclear monitoringElectricityContact high

The invention relates to the technical field of nuclear power and discloses a system for monitoring a pressure vessel of a reactor of a nuclear power station and a method thereof. The monitoring system contains a monitoring terminal which is disposed at the monitoring point of the monitored pressure vessel of the reactor and is used to acquire and send temperature information of the pressure vessel of the reactor; and a monitoring device which is electrically connected with the monitoring terminal and is used to receive the temperature information sent from the monitoring terminal and monitor the state of the pressure vessel of the reactor according to the temperature information. According to the invention, as there is no need to contact high temperature melts, the cost of the monitoring terminal can be reduced, its installation position is easy to determine and the acquired temperature information is effective and reliable. Based on the temperature information, the state of the pressure vessel of the reactor can be effectively monitored. The system for monitoring the pressure vessel of the reactor of the nuclear power station has a simple structure and requires low cost. The monitoring method provided by the invention is convenient to carry out and has high accuracy.

Owner:中广核工程有限公司 +1

Ramjet engine

InactiveCN104832318AAchieve normal startupAddress job stability issuesRam jet enginesRamjetJet engine

The present invention relates to a ramjet engine comprising an air inlet channel (14), a combustion chamber (5) and a tail jetting tube, wherein an air drainage structure is arranged at the inlet end of the air inlet channel (14) and comprises a high-pressure air input pipe (2), high-pressure air cavities (3) and nozzles (1); the high-pressure air cavities (3) are connected onto the air inlet channel (14); the high-pressure air in the high-pressure air input pipe (2) enters the high-pressure air cavities (3) and enters the air inlet channel (14) through the nozzles, thereby implementing the effect of introducing a large amount of air. According to the ramjet engine, the air drainage structure is arranged in the air inlet channel; the high-pressure air generated by gasifying a small amount of liquid air is jetted and is used for driving the surrounding air to output a large amount of low-pressure airflow at one end at a high speed, so that the start of the ramjet engine under the static pressure is implemented; the operation stability of the ramjet engine of an aircraft using the engine in a stall condition is achieved.

Owner:苟仲武

Gas filtration device

ActiveCN103961942AImprove filtering effectSimple structureDispersed particle filtrationElectricityElectrical conductor

The invention discloses a gas filtration device, which can facilitate gas filtration through heating gas entering the device. The gas filtration device comprises a casing and a filter element which is mounted inside the casing and is a conductor, wherein the casing is connected with the filter element in an insulated manner to form a first space and a second space which are separated from each other; the gas to be filtered is conveyed to the first space, the gas after filtration is conveyed to the second space; a positive pole connecting end and a negative pole connecting end are arranged on the filter element; during filtration, the positive pole connecting end and the negative pole connecting end are connected with a positive pole and a negative pole of a power supply respectively to form a closed circuit so as to enable the filter element to form a filtration component serving as an electric heating body; the heating power of the electric heating body can enable the temperature of the gas at the gas inlet lower than or equal to the temperature of the gas at the gas outlet; even the gas to be filtered contains substances which is condensed due to a low temperature, the holes of the filter element are not blocked by the precipitation of the substances during the filtration.

Owner:CHENGDU INTERMENT TECH

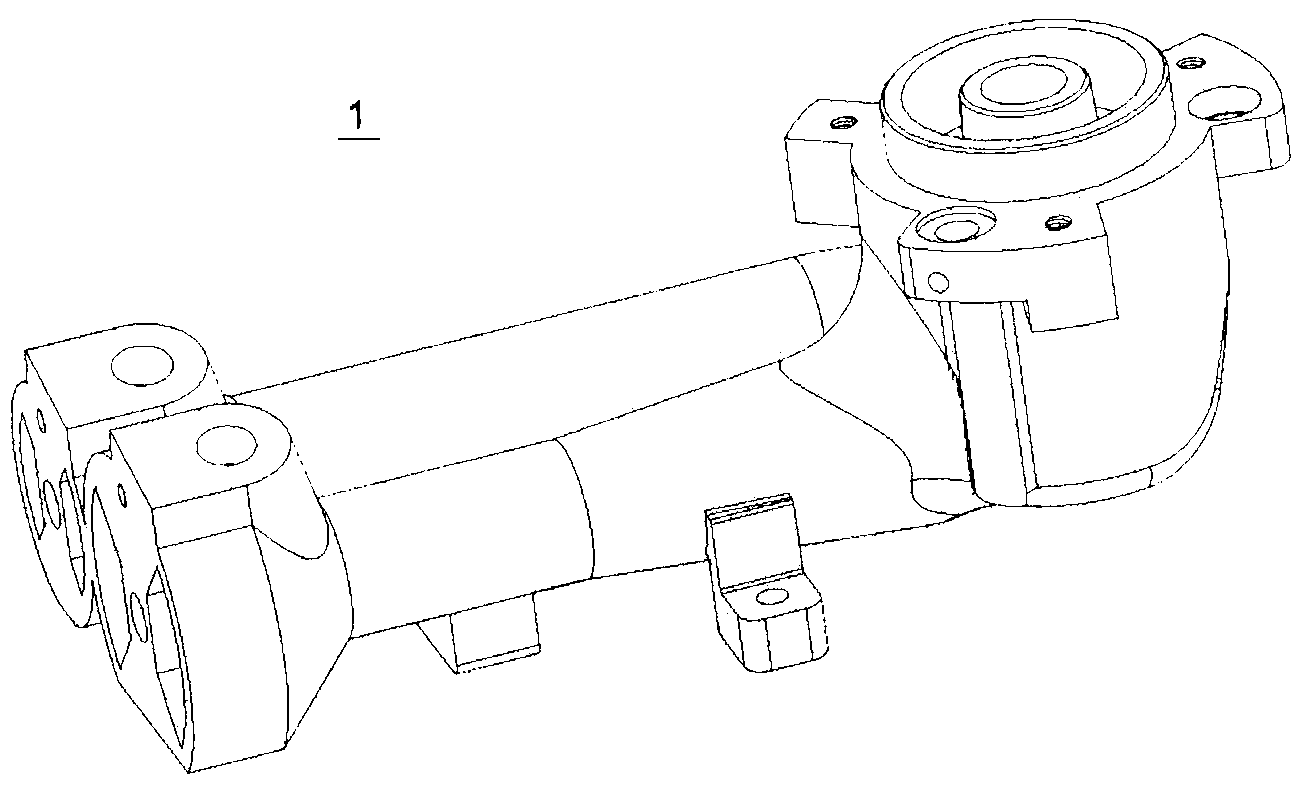

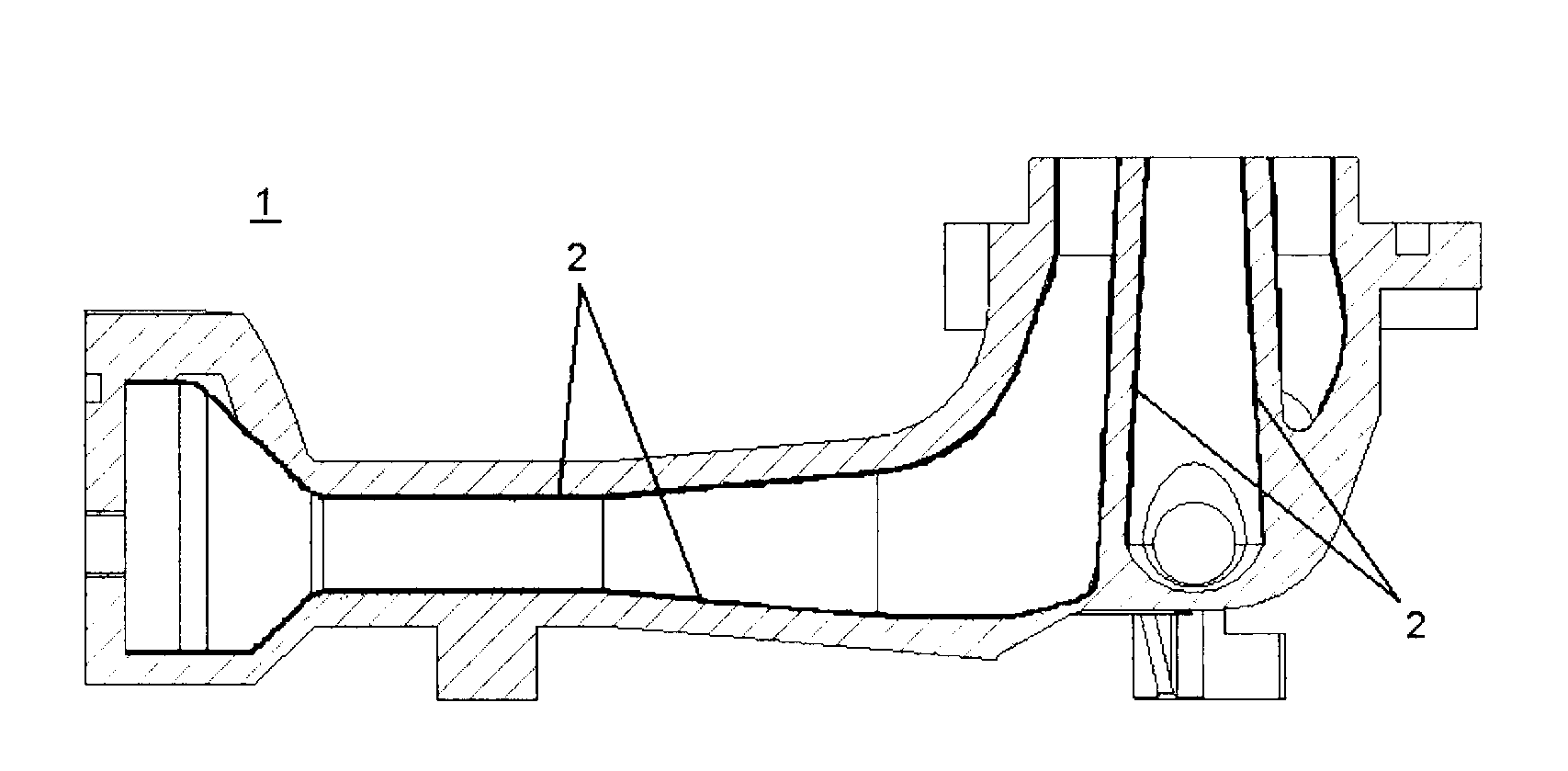

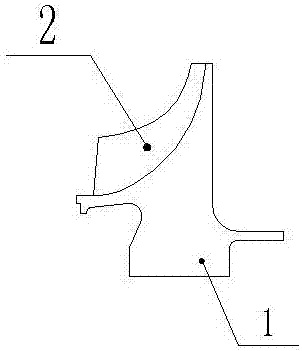

Ejector and gas stove provided with ejector

InactiveCN103162296AGood air conduction effect on the inner wallReduce high temperature requirementsDomestic stoves or rangesGaseous fuel burnerEngineeringProduct gas

The invention provides an ejector and a gas stove provided with the ejector, wherein the inner wall of the ejector is good in gas guiding effect. According to the ejector, a coating is arranged on at least part of the inner wall of the ejector, wherein the coating is high-temperature resisting and the surface of the coating is smooth. The probability of the occurrence of turbulence of gas can be obviously reduced when the gas flow through the ejector, and then the gas is enabled to flow smoothly.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

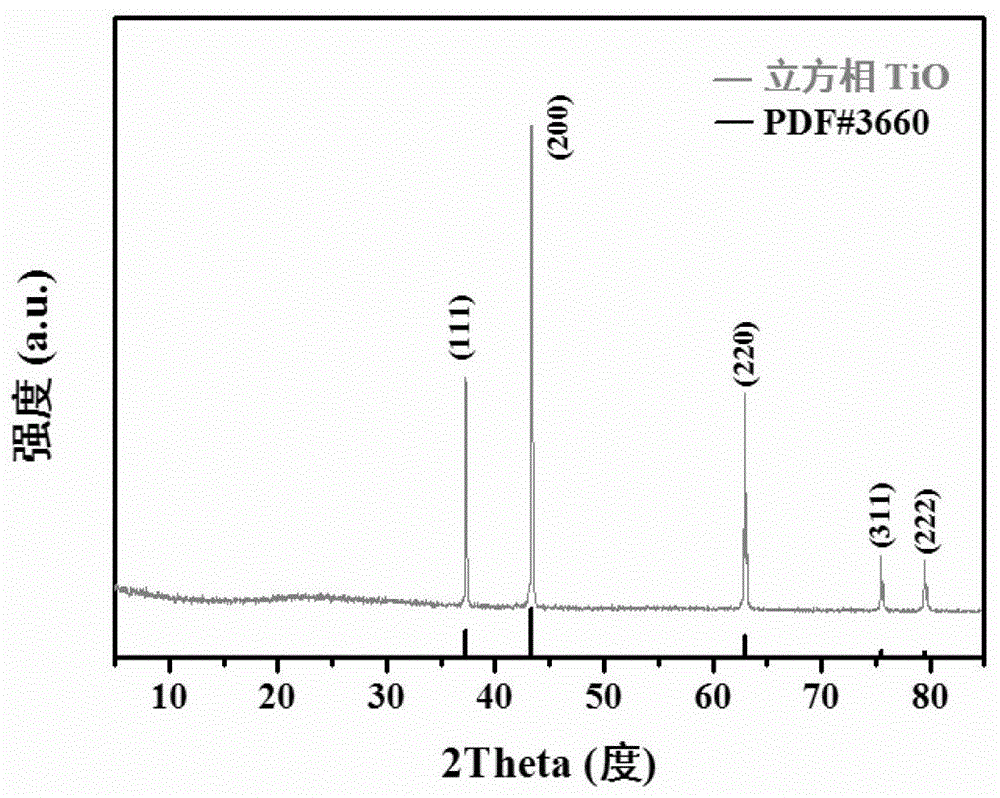

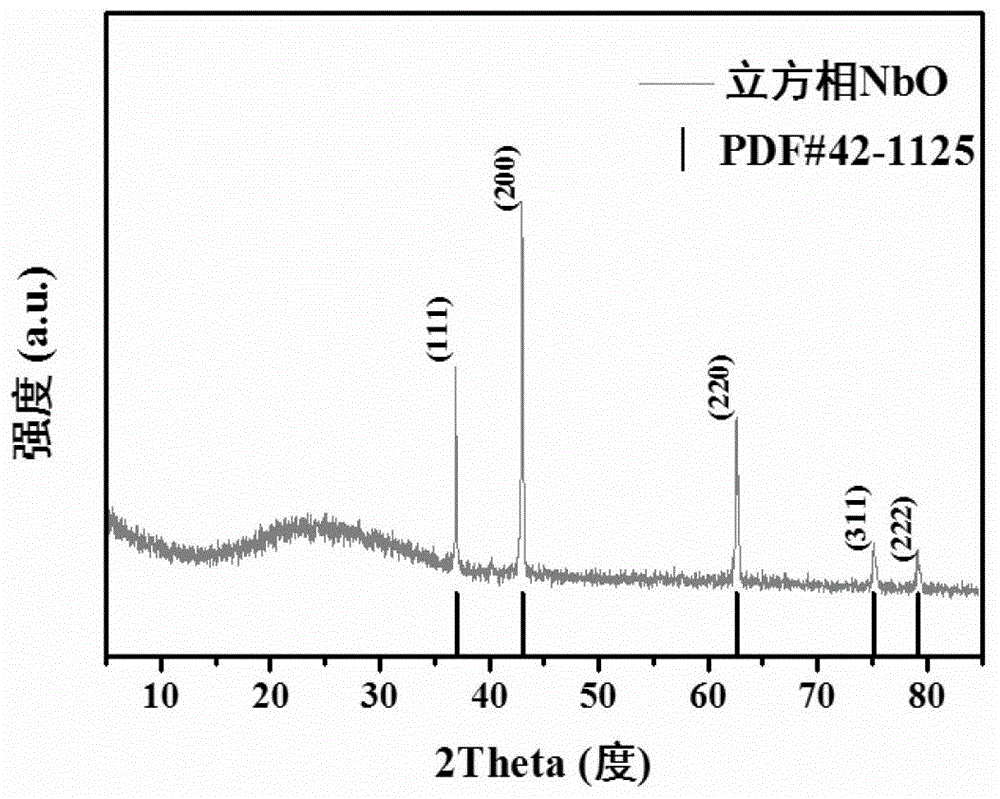

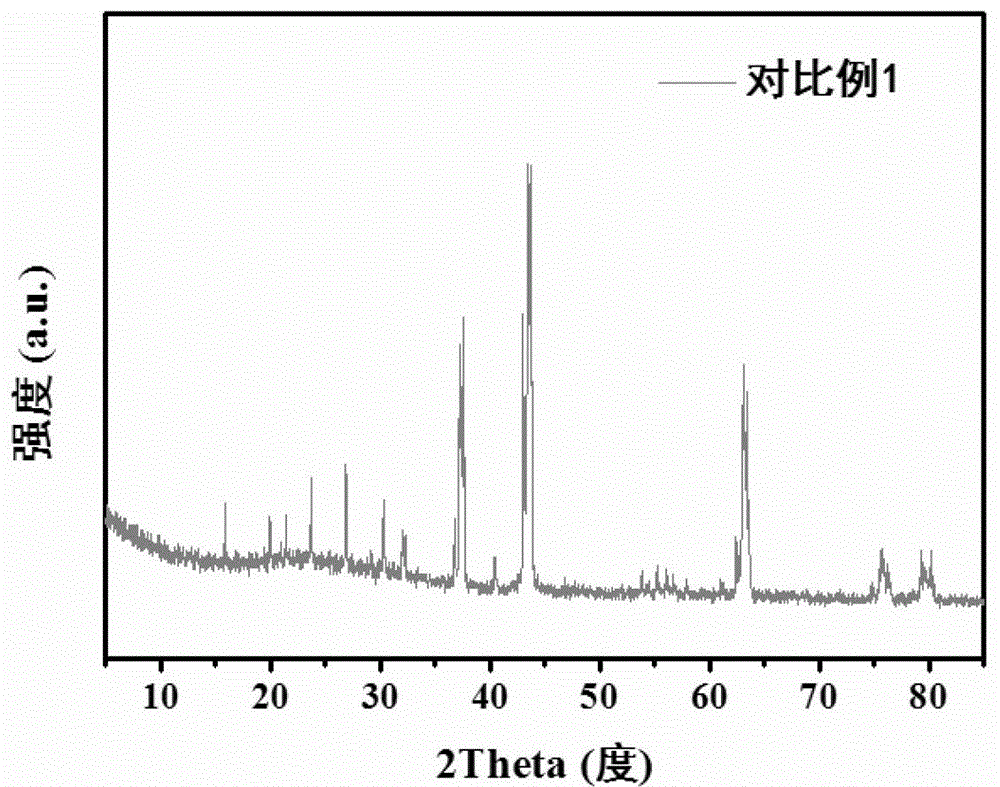

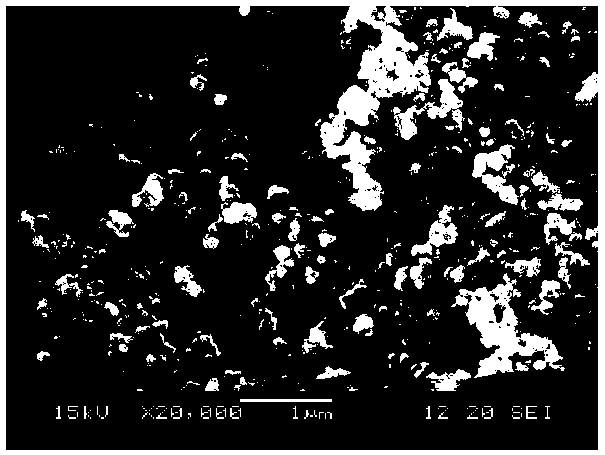

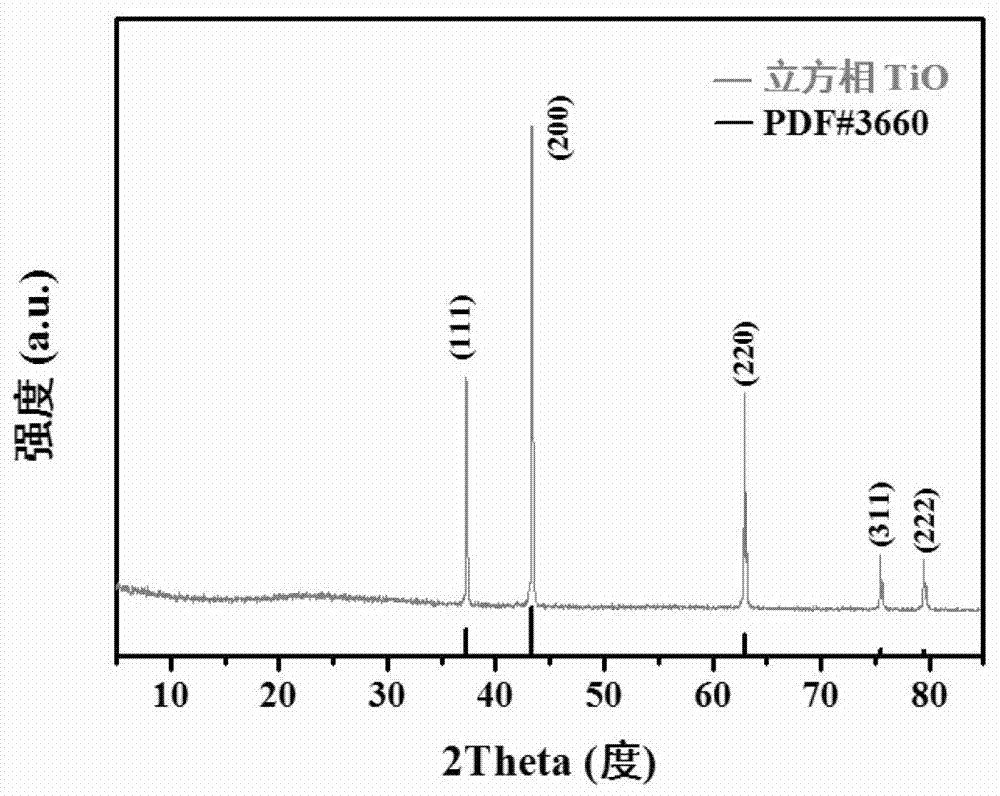

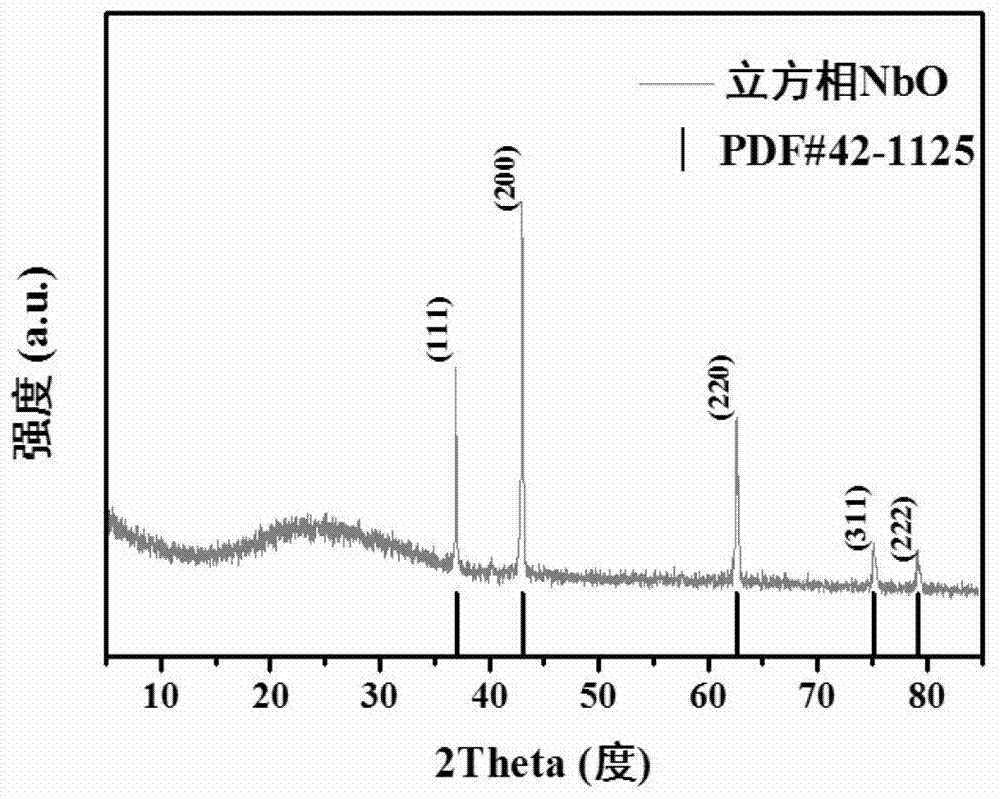

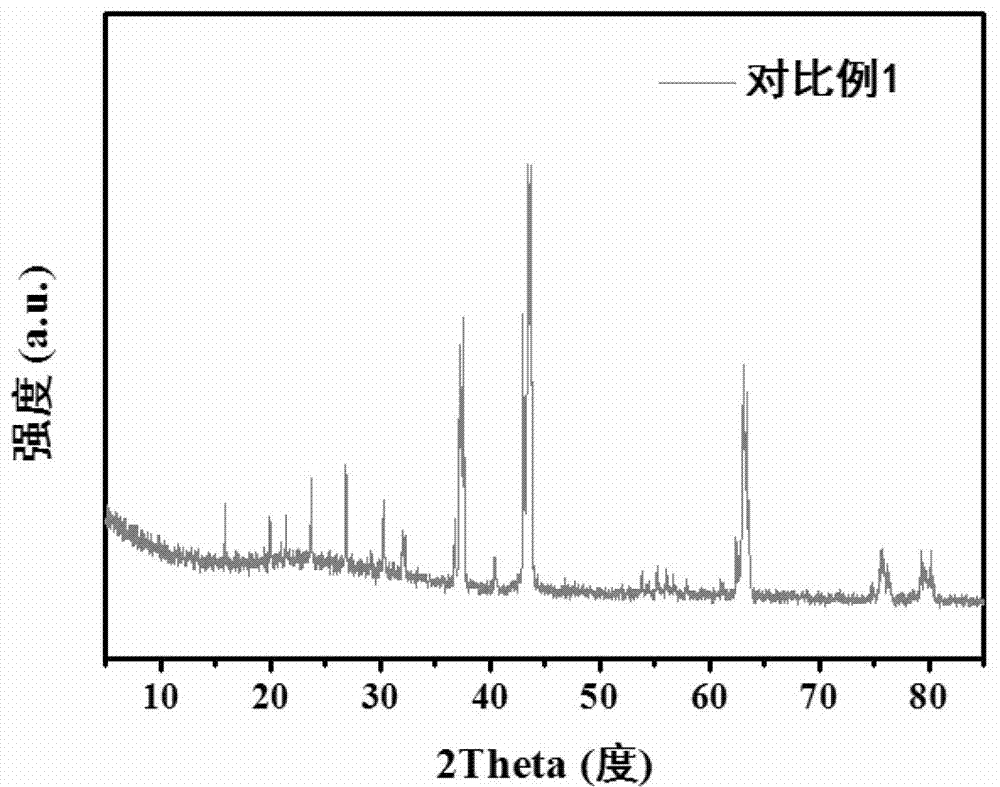

Methods for preparing transition metal monoxide powder, target material and film

The invention provides methods for preparing transition metal monoxide powder, target material and film. The methods comprise the following steps: transition metal M powder and transition metal M oxide powder in a mole ratio being 1:1-1.2:1 are taken as reaction raw materials and sufficiently mixed with alkali halide with mass being 0.5-2.5 times, preferably, 0.5-2 times of the total mass of the reaction raw materials, the mixture is packaged in a reactor in a vacuum manner and reacts at 900-1,100 DEG C for 5-10 h, and the transition metal monoxide powder is obtained; the transition metal monoxide powder is subjected to spark plasma sintering, and the transition metal monoxide target material is obtained; a film grows on the transition metal monoxide target material, and the transition metal monoxide film is obtained. The transition metal monoxide powder, target material and film can be prepared rapidly at low temperature with the methods.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of synthetic method of antitumor drug

ActiveCN104817541BHigh yieldMild reaction conditionsCarbamic acid derivatives preparationOrganic compound preparationCarbamateMethyl-1H-indole

The invention relates to a synthetic method of an anti-tumor medicine, namely N-[2-[[2-(dimethylamino) ethyl] methyl amino]-4-methoxy-5-[[4-(1-methyl-1H-indole-3-yl)-2-pyrimidyl] amino] phenyl]-2-acrylamide (AZD9291) and a key intermediate of the anti-tumor medicine. The synthetic method comprises the following steps: performing Boc acid anhydride protection on 4-fluoro-2-methoxy-5-nitroaniline to obtain 4-fluoro-2-methoxy-5-nitroanilino tert-butyl formate, then reacting with N,N,N'-trimethylethylenediamine to obtain 4-(N,N,N'-trimethylethylenediamino)-2-methoxy-5-nitroanilino tert-butyl formate, then reducing to obtain 2-(N,N,N'-trimethylethylenediamino)-4-methoxy-5-tert-butyl carbamate phenylamine, then completely reacting with acryloyl chloride and directly removing a Boc protecting group to obtain 2-methoxy-4-N,N,N'-trimethylethylenediamino-5-acrylamido phenylamine, and finally reacting with 3-(2-chloropyrimidine-4-yl)-1-methylindole to obtain AZD9291. A process disclosed by the invention is simple in step, relatively high in yield, mild in reaction condition and easy for realization of industrial production.

Owner:苏州东南药业股份有限公司

Yttrium cathode for magnetron tungsten of microwave oven and preparation process thereof

ActiveCN102800542ASolve the radiationReduce high temperature requirementsTransit-tube cathodesManufacturing cost reductionWorking temperature

The invention discloses a tungsten yttrium cathode for a magnetron of a microwave oven. The tungsten yttrium cathode is characterized by comprising the following components in percentage by weight: 0.3 to 3 percent of yttrium, and the balance of tungsten. The invention also discloses a preparation process for the tungsten yttrium cathode for the magnetron of the microwave oven. The tungsten yttrium cathode has brittleness and high temperature performance of products, enhances the plasticity of the products, has good working performance, high plasticity, low production cost and no radiation, reaches the same working effect and greatly reduces the working temperature, so that the tungsten yttrium cathode can greatly reduce the requirements of high temperature resistance of electrode metal materials, meets the requirements on environmental protection, and obviously reduces the manufacturing cost at the same time.

Owner:佛山宁宇科技股份有限公司

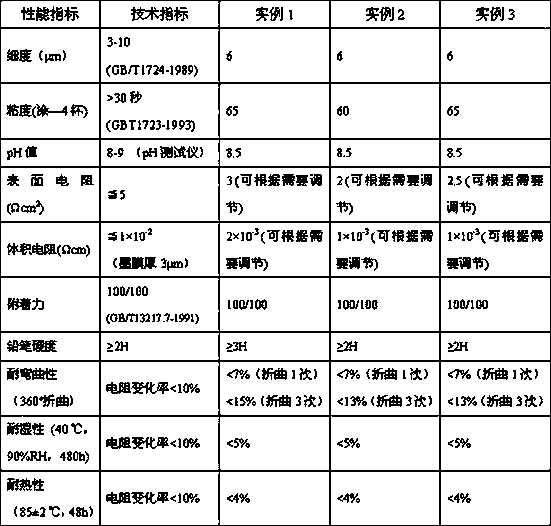

Water-soluble graphene electric-conduction ink and preparation method thereof

The invention provides a water-soluble graphene electric-conduction ink and a preparation method thereof, wherein the water-based graphene electric-conduction ink composite material comprises water-soluble graphene powder, a linking resin material, an auxiliary agent and a solvent. According to the present invention, the large-batch water-soluble graphene electric-conduction ink can be prepared according to the experimental method of the present invention; deionized water is used as the solvent to replace the traditional organic solvent, the linking resin is selected, and the ratio is used, such that the water-soluble graphene electric-conduction ink having characteristics of good electric conductivity, good toughness, good compression molding and good impact resistance and meeting the adhesion requirement is blended; based on the excellent electric conductivity of the graphene component, the electric conduction stability of the product is increased, and the resistivity is reduced; andthe disadvantages of environment pollution and high cost of the traditional electric-conduction ink are overcome, and the water-soluble graphene electric-conduction ink is expected to be mass-produced.

Owner:厦门泰启力飞科技有限公司

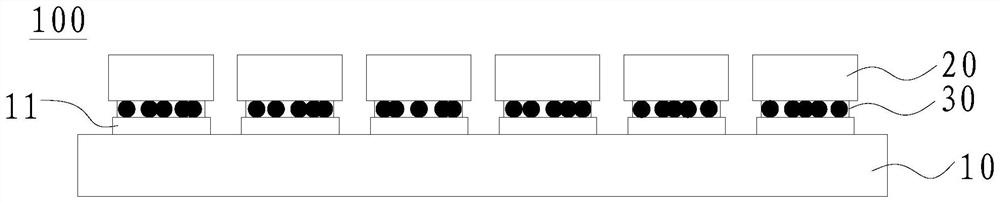

LED chip die bonding method and LED panel

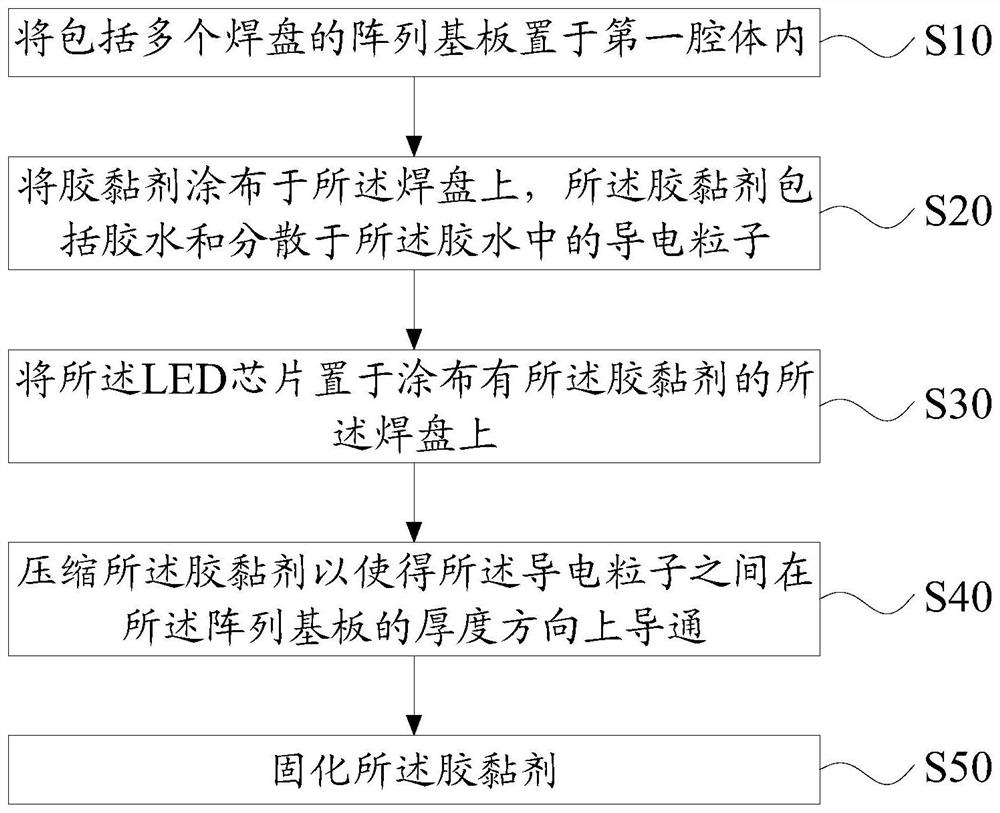

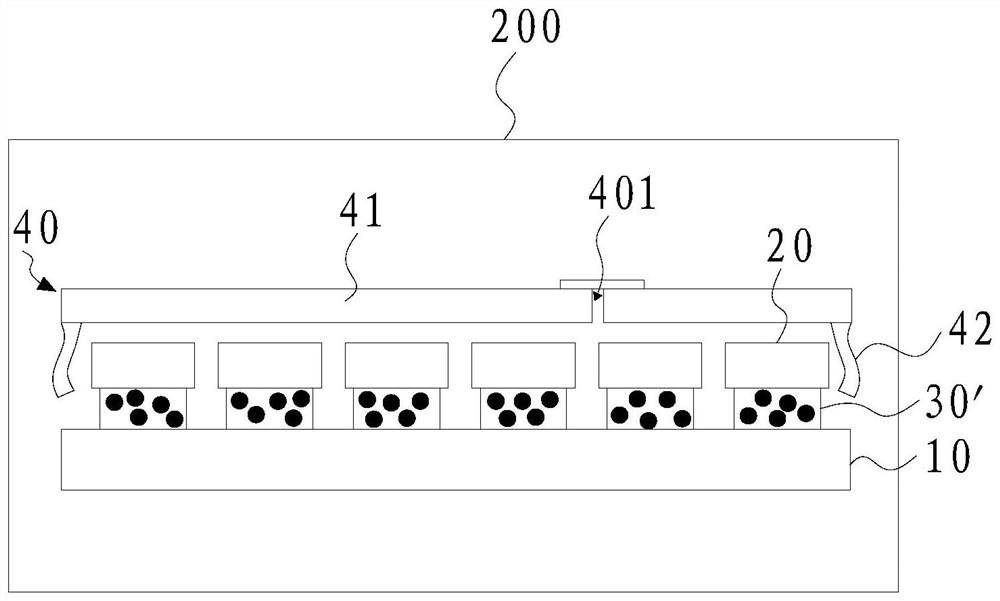

PendingCN114420717AAvoid high temperature processReduce high temperature requirementsSolid-state devicesSemiconductor devicesAdhesive glueElectrically conductive

The embodiment of the invention discloses a die bonding method of an LED chip and an LED panel. The die bonding method comprises the following steps: S10, placing an array substrate comprising a plurality of bonding pads in a first cavity; s20, coating the bonding pad with an adhesive, wherein the adhesive comprises glue and conductive particles dispersed in the glue; s30, the LED chip is placed on the bonding pad coated with the adhesive; s40, compressing the adhesive to enable the conductive particles to be conducted in the thickness direction of the array substrate; and S50, curing the adhesive. According to the LED chip die bonding method provided by the embodiment of the invention, the conductive particles are dispersed in the glue to replace solder paste in the prior art to realize die bonding of the LED chip, so that on one hand, the high-temperature process of solder paste reflow soldering can be avoided, the high-temperature-resistant requirement on the LED chip and an array substrate selected material can be reduced, and the residual thermal stress influence of the high-temperature process can be reduced; on the other hand, different glue materials can be selected according to different application requirements, the material selection is diversified, and the flexible application degree of the process is high.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

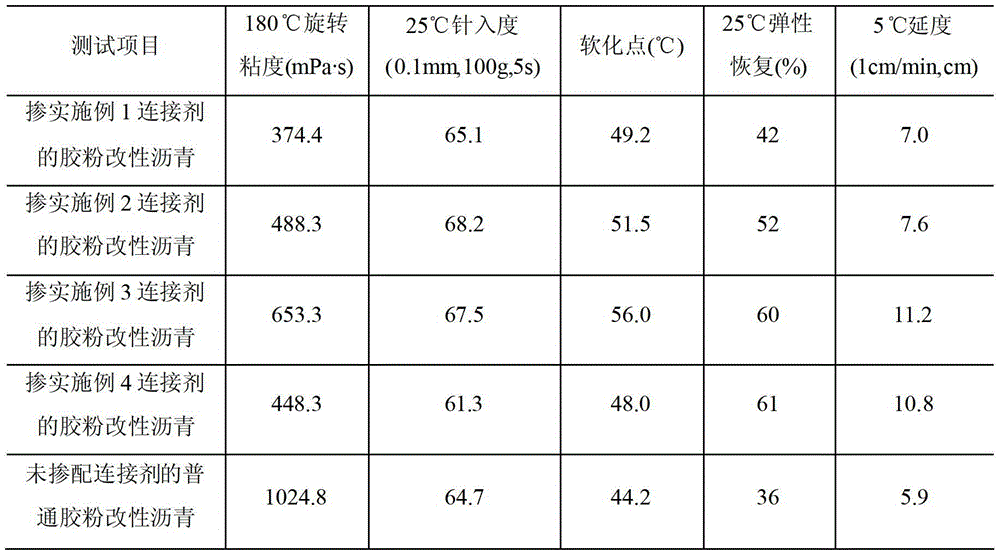

A kind of rubber powder modified asphalt linking agent and preparation method thereof

ActiveCN103232709BReduce high temperature requirementsImprove road performanceBuilding insulationsWater bathsCrack resistance

The invention belongs to the technical field of modified bitumen auxiliaries, and in particular relates to a rubber powder modified bitumen bridging agent and a preparation method thereof. The bridging agent is prepared form the following raw materials in parts by mass: 70-90 parts of deionized water, 10-30 parts of styrene, 2-30 parts of amide functional monomers, 0.75-2 parts of an initiator and 0-2 parts of an emulsifier through the emulsion polymerization. The method specifically comprises steps of: sequentially taking and putting the deionized water, the emulsifier, the amide functional monomers, the styrene and the initiator into a reactor; uniformly stirring, heating to react for 5-7 hours through a water bath, and thus obtaining the uniform polymer emulsion; and removing water and unreacted monomers in the polymer emulsion, and drying to obtain the rubber powder modified bitumen bridging agent. Compared with the prior art, the bridging agent prepared by the method can be used for lowering the high-temperature requirements of a rubber powder modified bituminous mixture in producing, laying and grinding processes, so that pollution is reduced, the performances such as high-temperature track resistance, low-temperature crack resistance, durability and aging resistance of the rubber powder modified bitumen can be obviously improved.

Owner:山西省交通新技术发展有限公司

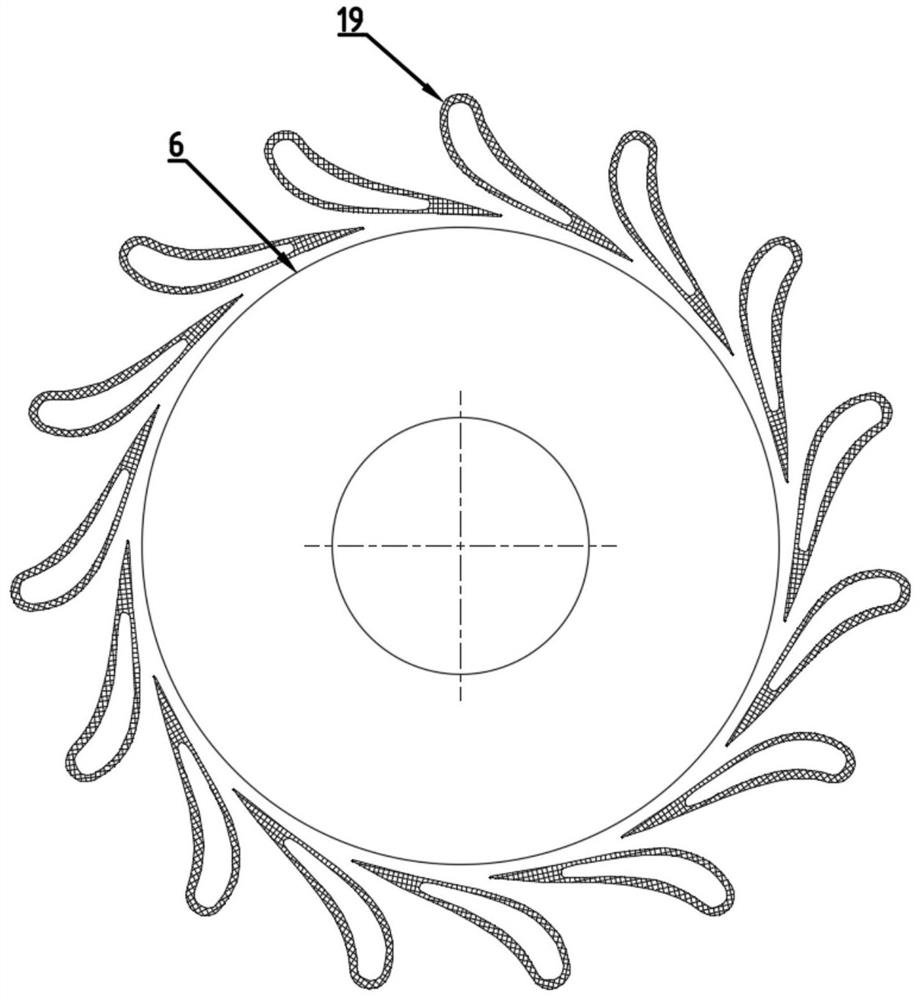

hollow centrifugal impeller

ActiveCN105298911BImprove carrying capacityReduce high temperature requirementsPump componentsPumpsAxial displacementImpeller

The invention provides a hollow centrifugal impeller. According to the hollow centrifugal impeller, the centrifugal impeller is divided into n divisions; the divided divisions are all vertical to the axis of the centrifugal impeller; the materials used by the divisions are determined according to the working conditions of different parts of the centrifugal impeller on which the divisions are located; a cavity is formed in the centrifugal impeller; the cavity is located in an area, which is low in stress according to measurement, of a conventional monometallic solid impeller; and the number n of the divisions is larger than or equal to 2. Compared with the conventional monometallic solid impeller, the hollow centrifugal impeller is advantaged in that the weight of the impeller can be effectively reduced; the stress of the impeller is lowered; the service life of the impeller is prolonged; the axial displacement of the outlet of the centrifugal impeller is greatly reduced, so that blade tip clearance design is facilitated; and the economy and practical application performance are improved.

Owner:CHINA AVIATION POWER MACHINE INST

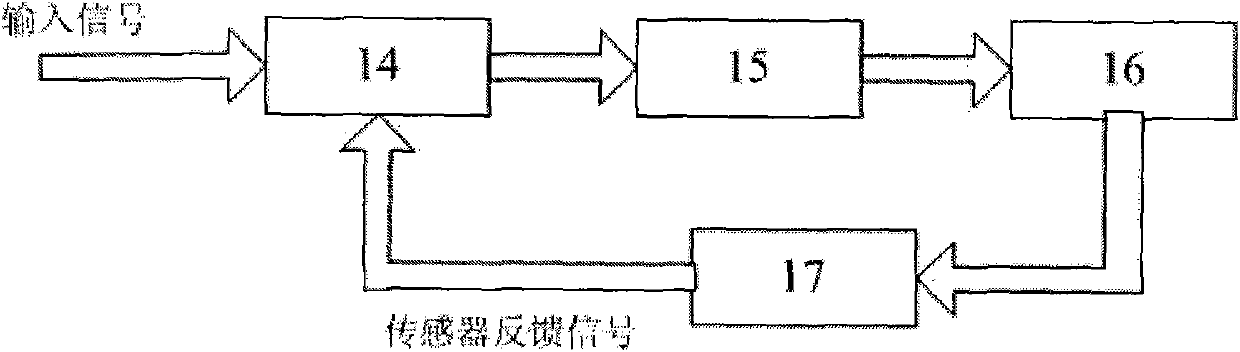

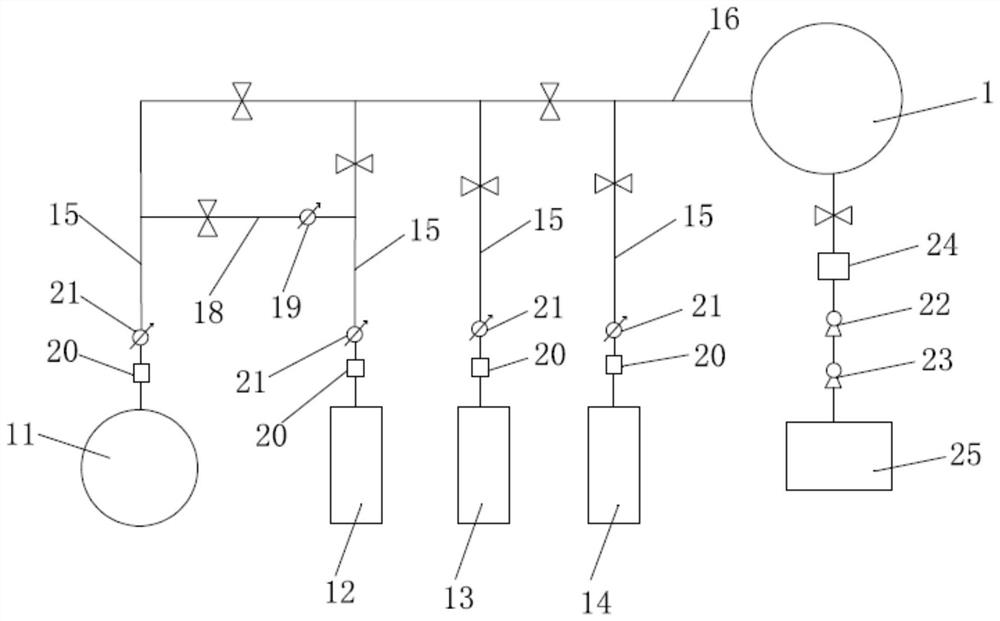

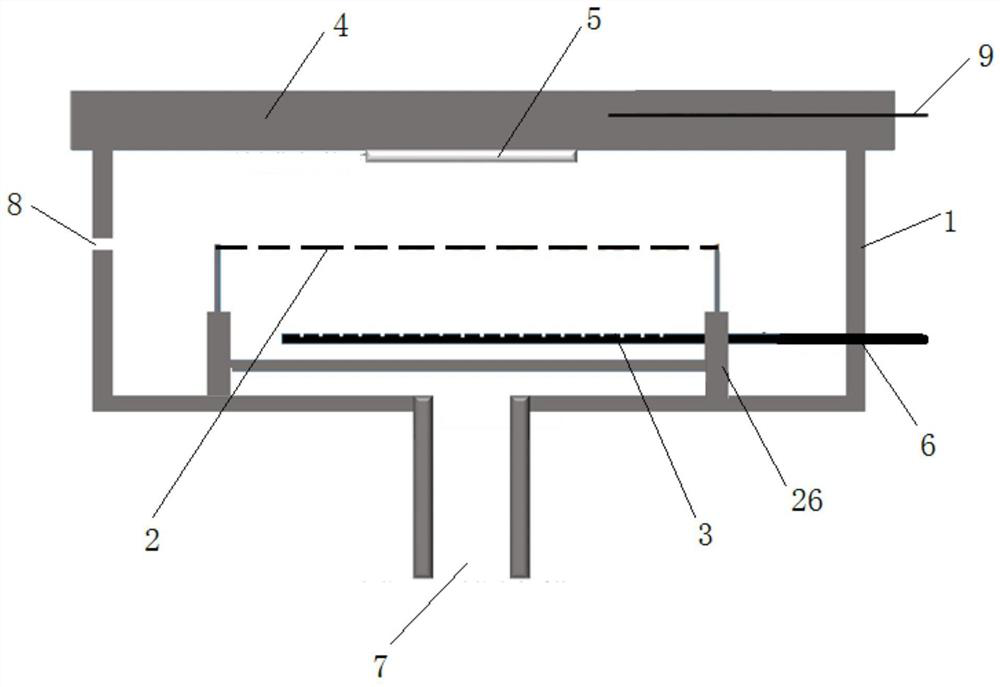

Flexible quasi-SIOx thin film growth device

PendingCN111793791AReduce high temperature requirementsMultiple choiceChemical vapor deposition coatingCarbon monofluorideSilicon oxide

The invention discloses a flexible quasi-SIOx thin film growth device. The device comprises a reaction cavity, a gas path system, a control system, a vacuum system and a tail gas treatment system, wherein the gas path system, the control system, the vacuum system and the tail gas treatment system are connected with the reaction cavity. A radio-frequency electrode is horizontally arranged in the reaction cavity in a suspended manner and is connected with the positive pole of a radio-frequency power source, and the reaction cavity is connected with the negative pole of the radio-frequency powersource. A gas even mixer is arranged below the radio-frequency electrode. A substrate used for thin film deposition is fixedly to the inner side of a top cover of the reaction cavity. The gas even mixer is connected with the gas path system. A first gas outlet is formed on the reaction cavity to be connected with the vacuum system. The gas path system comprises a hexamethyldisiloxane storage tank,a nitrogen storage tank, an oxygen storage tank and a carbon tetrafluoride storage tank, each storage tank is connected with a main pipeline at the front end of the reaction cavity through a branch pipeline, and the main pipeline is connected with the gas even mixer. By means of the device, a flexible quasi-SIOx thin film can be prepared under the room temperature, good packaging performance is achieved, and the flexible quasi-SIOx thin film can be used as a good flexible insulation medium material.

Owner:SHANDONG UNIV

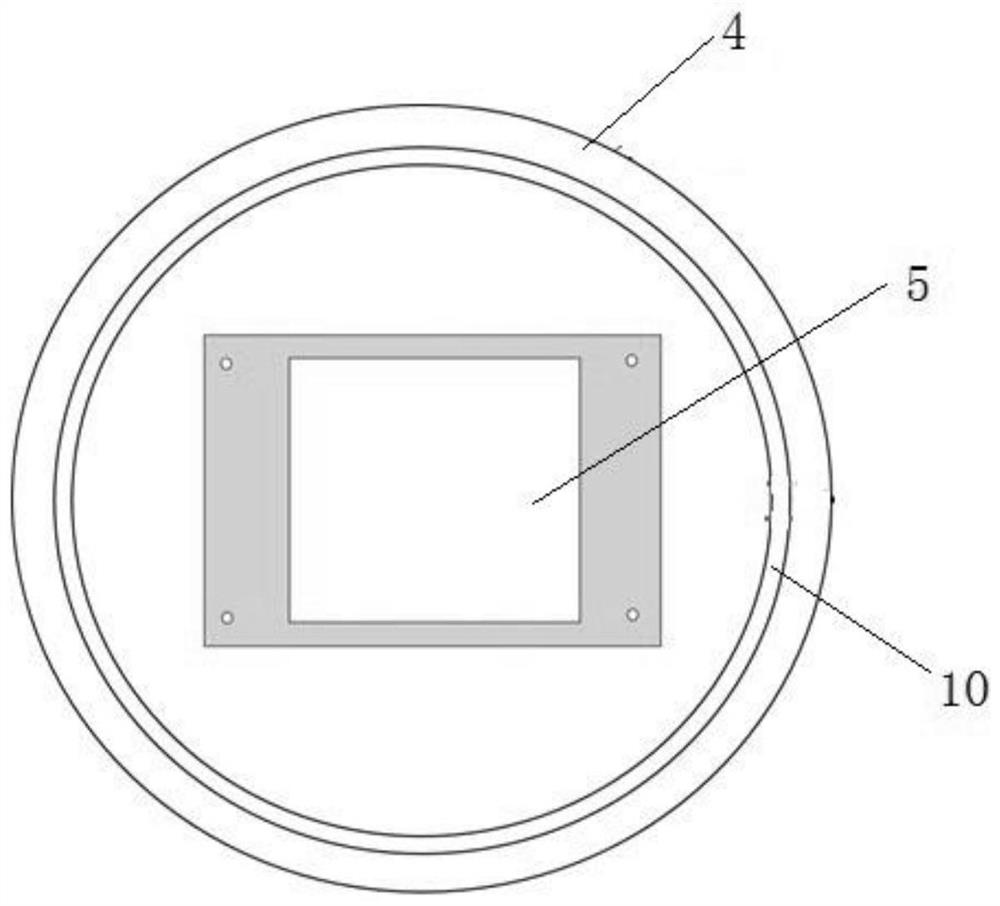

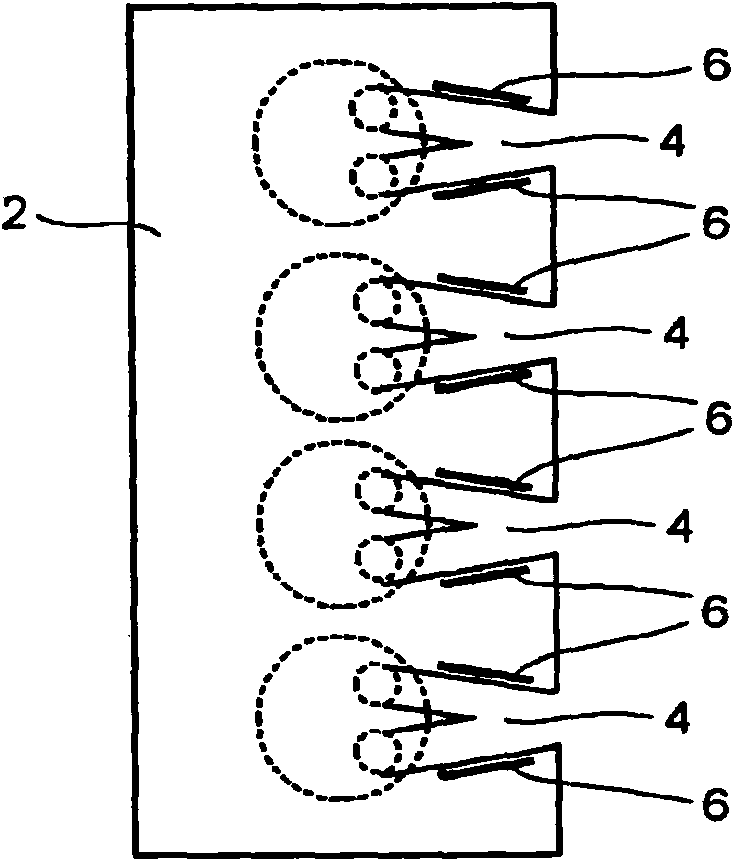

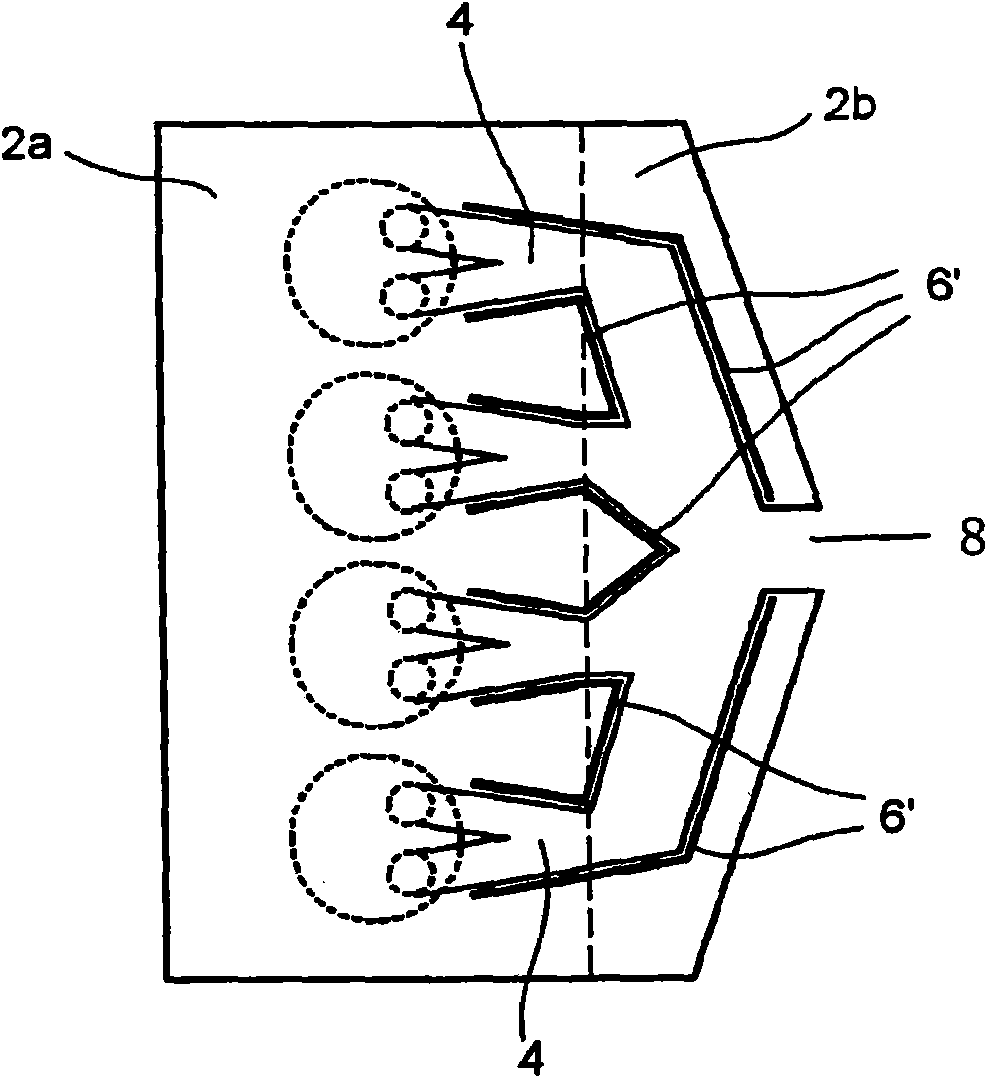

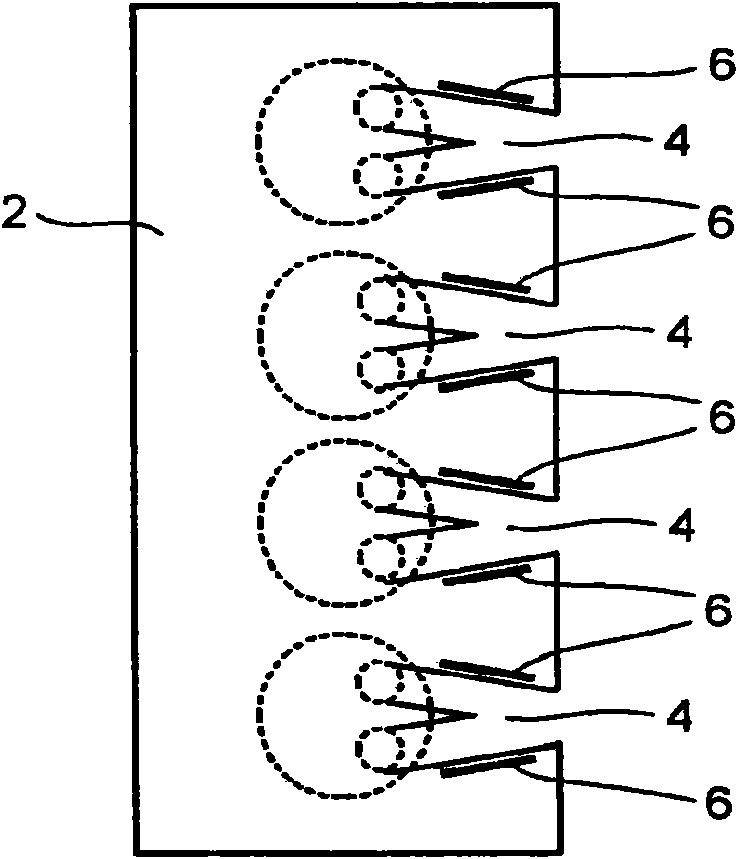

Internal combustion engine with thermoelectric generator

InactiveCN102213128AImprove cooling effectSmall sizeInternal combustion piston enginesHeat recovery systemsExternal combustion engineCylinder head

The invention relates to an internal combustion engine with one or more thermoelectric generators (6). The thermoelectric generator generates the current by a temperature difference between the exhaust of the internal combustion engine and a coolant. According to the invention, at least a thermoelectric generator is in thermal contact with an exhaust duct section (4) of the internal combustion engine near a combustion chamber at a heat supply side and is in thermal contact with the coolant for cooling the internal combustion engine and / or a heat conductive member of a cylinder cover (2) at a heat radiation side.

Owner:FORD GLOBAL TECH LLC

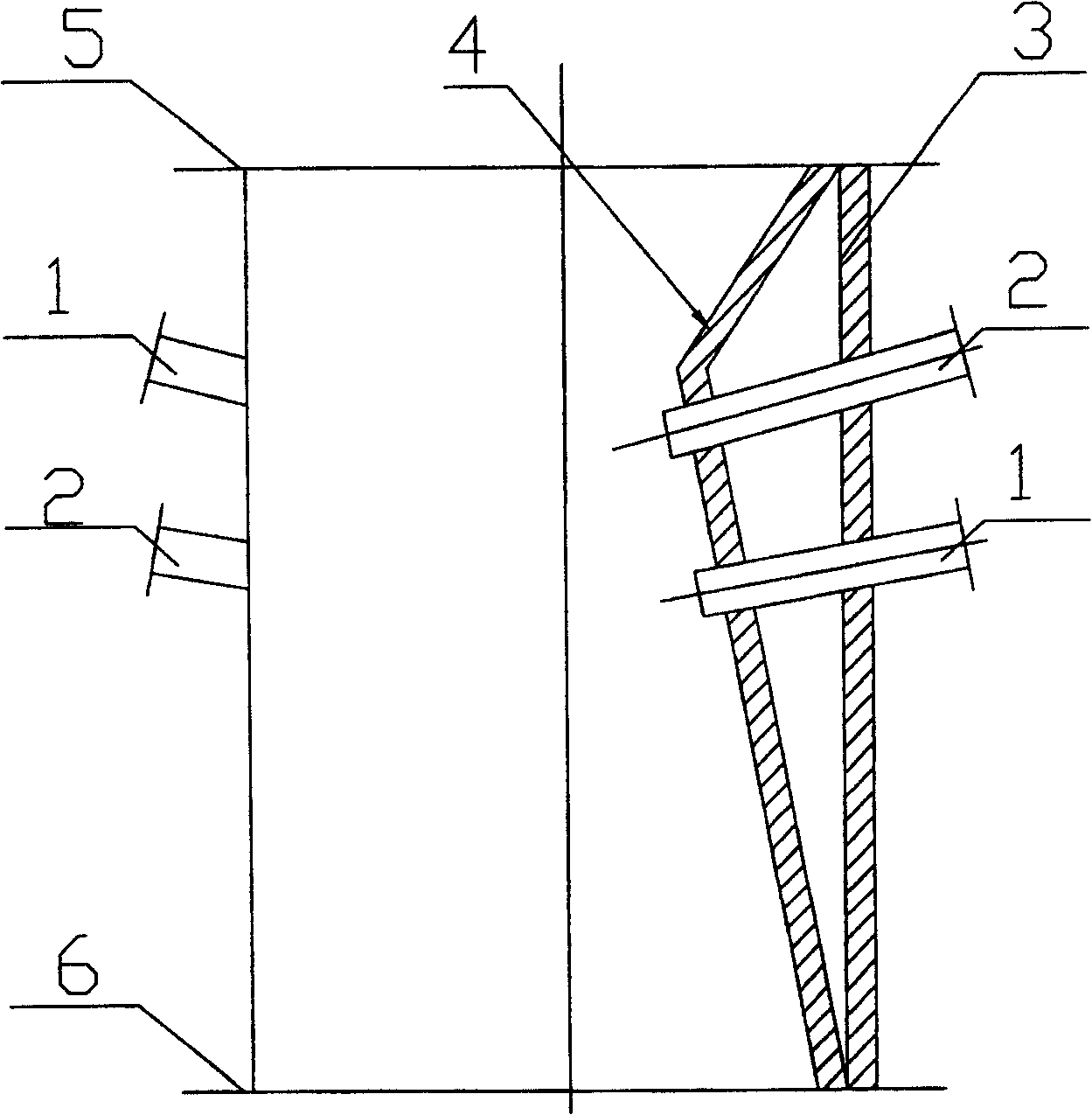

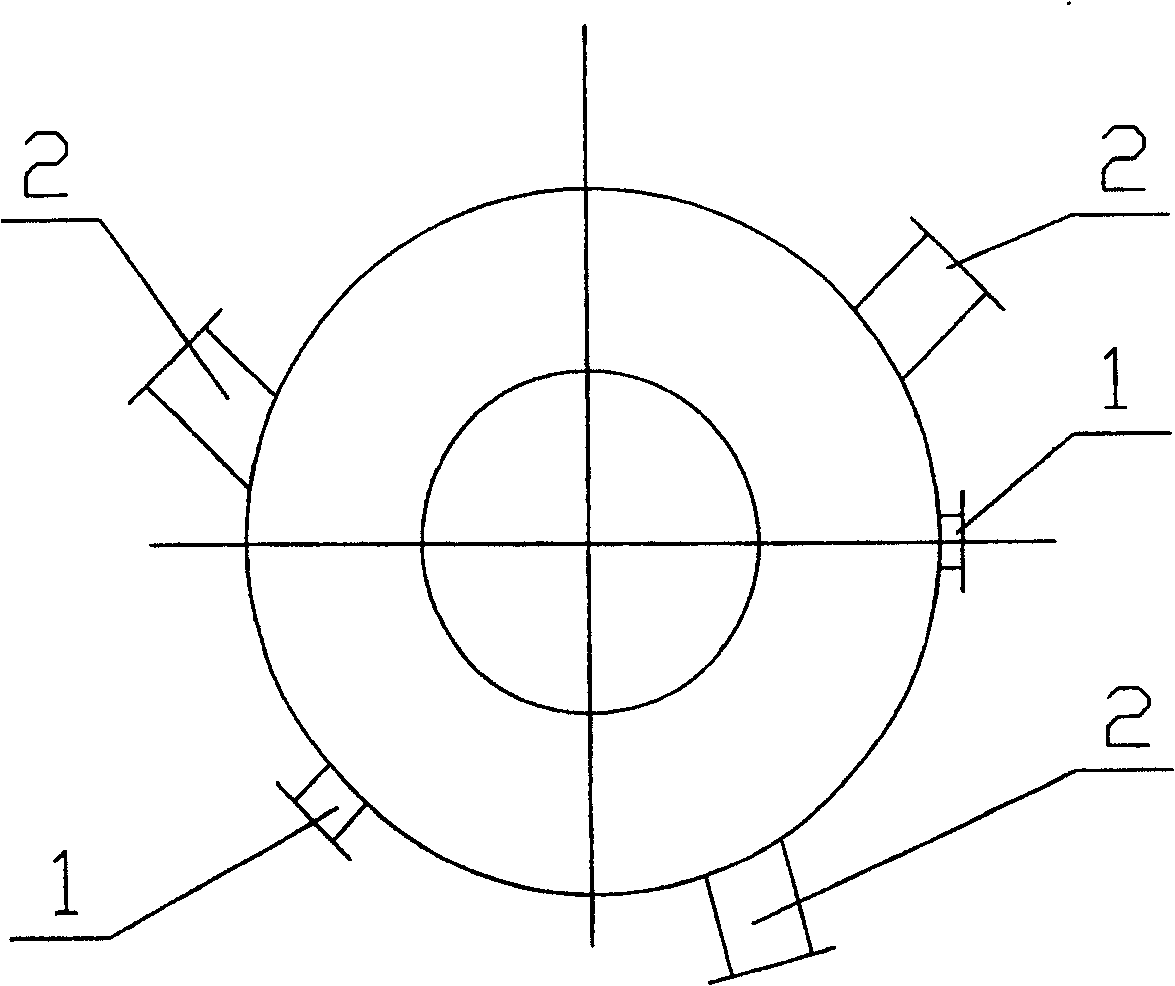

Device for preventing generation of dioxin in refuse burning device

InactiveCN100458286CPrevent regenerationReduce chance of recombinationIncinerator apparatusEngineeringSpray tower

Aiming to prevent his production of dioxins in waste burning, the invention comprises an extendable pipe that speeds up the air flow and connects in series with the exhaust pipe of the No.2 burning chamber, with top and bottom ends of the extendable pipe connecting with the exhaust pipe and the spray tower flange. The double layer structure extendable pipe has inner layer with extendable pipe 4, and the outside layer with a cylindrical tube 3 of same caliber with that of the exhaust pipe of the No.2 burning chamber. At the extendable neck, there are 2-4 fountain heads going through the cylindrical pipe 3 and the extendable pipe 4. It can spray cooling water when the smoke goes to the extendable neck speeding up dramatically, reducing temperature of the 1100DEG C high smoke to that below 200DEG C, effectively avoiding the regeneration of dioxins and protecting the environment.

Owner:龚德明

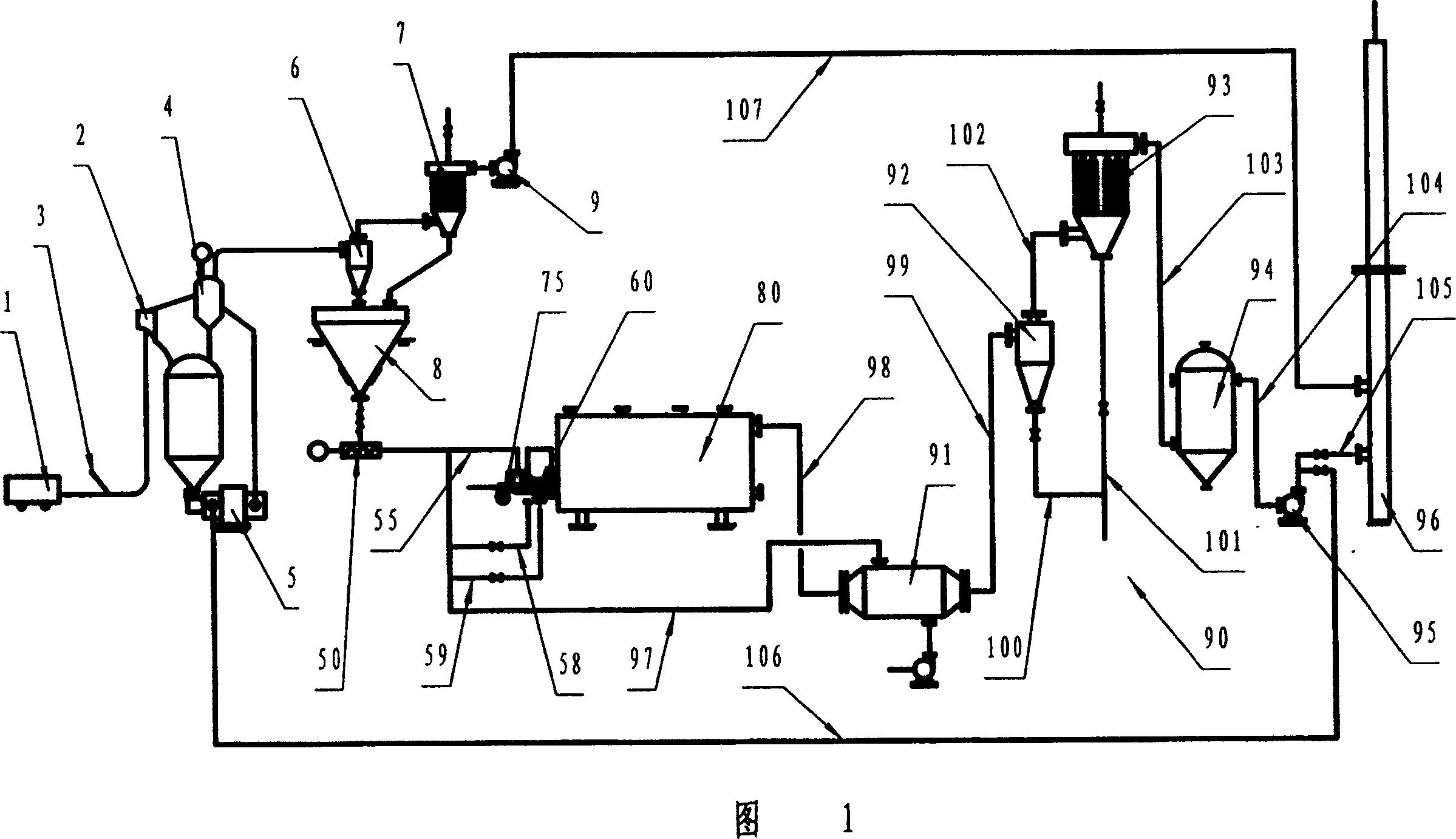

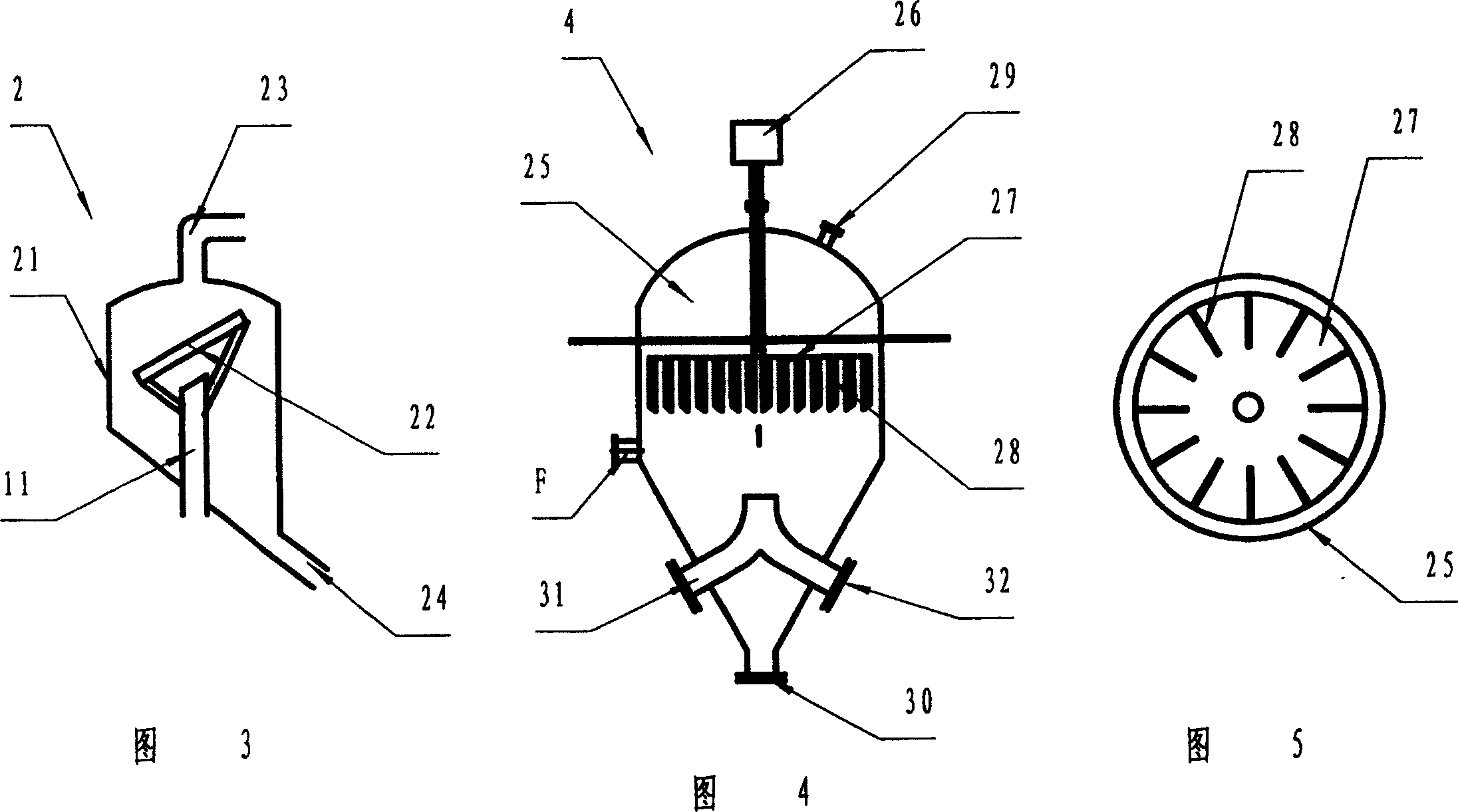

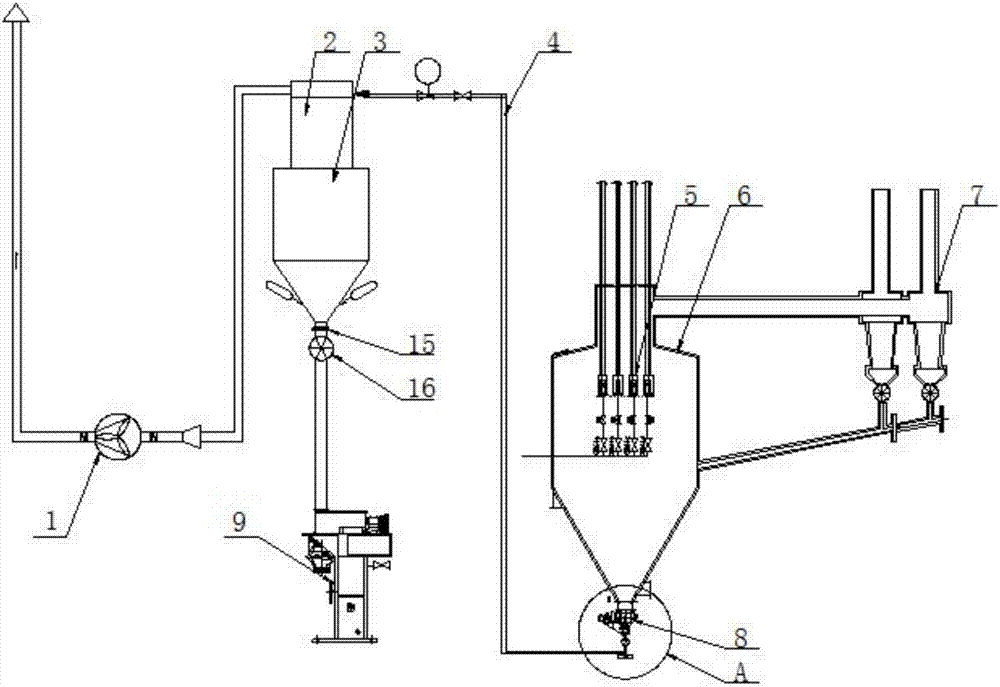

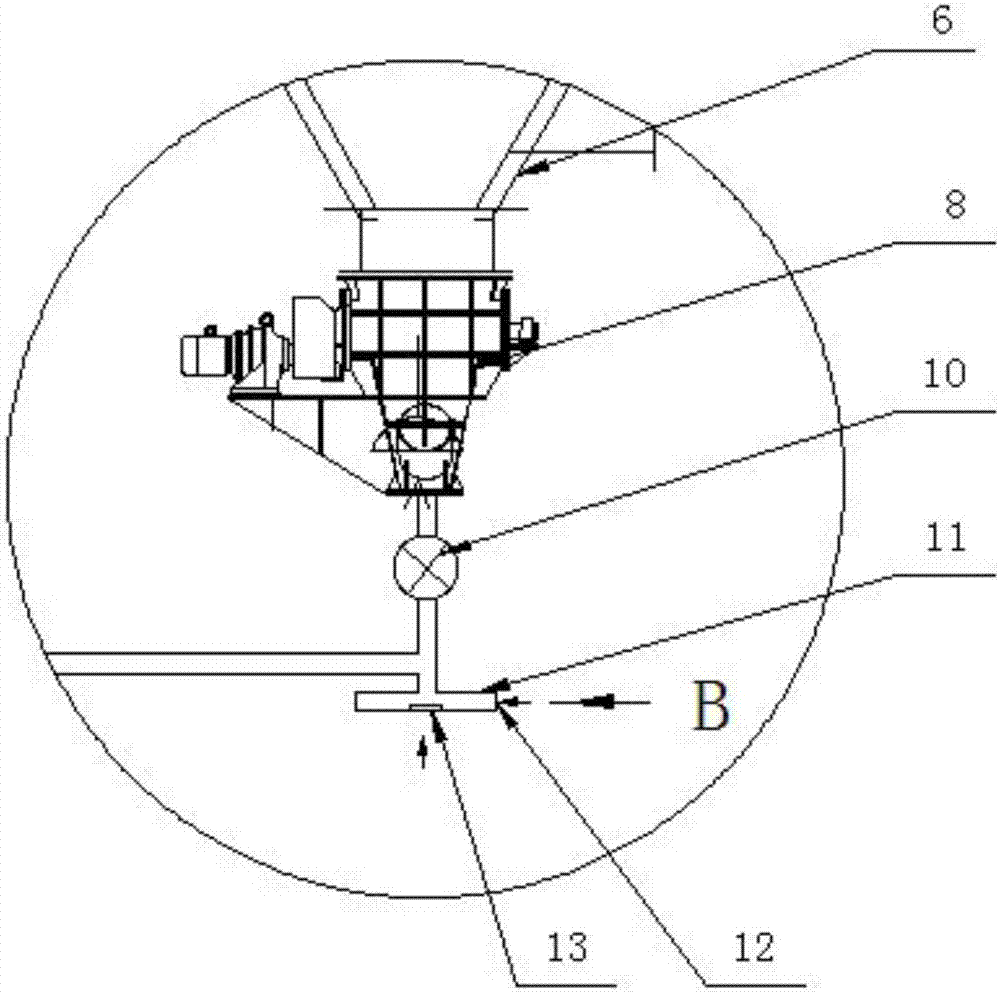

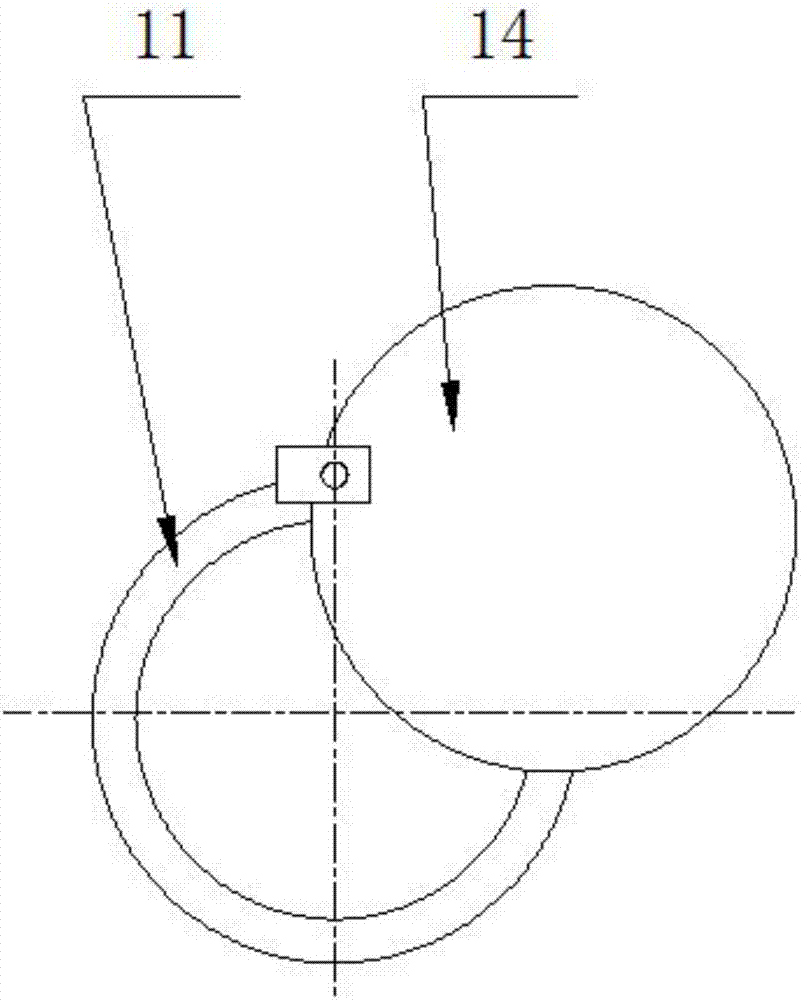

Medium and small sized industrial pulverized-coal fired boiler

ActiveCN1328539CGuaranteed combustion requirementsOvercoming easy clumpingIndirect carbon-dioxide mitigationFire-tube steam boilersCycloneAutomatic control

A system of industrial pulverized - coal fired boiler in small or medium size comprises stokehole pulverizing unit including high pressure air pump , baffle separator , coal supplying pipe , etc ; pulverized coal supplying unit including coal conveying pipe , blanking pipe and air supplying pipe ; pulverized coal combustion unit including central air pipe , primary air pipe , internal and external secondary air pipe ; boiler body including shell , heating stove , two and three returning pipes ; dust removal and desulfurization unit including cyclone separator , bag-duster, desulfurization tower, exhaust fan and chimney. Advantages: fine pulverized coal with grain size above 200 mesh, good low-temp. combustion effect and high heat efficiency

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

A cooling treatment system for iron oxide powder in acid regeneration station

ActiveCN105836810BReduce high temperature requirementsReduce the temperatureFerric oxidesPreparation from chloridesIron powderCooling effect

The invention relates to an acid regeneration station ferric oxide powder cooling treatment system. According to the acid regeneration station ferric oxide powder cooling treatment system, a block breaker and a roasting furnace rotating valve are mounted at the bottom discharge hole of a roasting furnace; the bottom discharge hole is further connected with a ferric oxide powder conveying pipeline; the ferric oxide powder conveying pipeline is connected with a ferric oxide powder bin through a plastic plate dust separator; a conveying fan is mounted on the ferric oxide powder conveying pipeline; a ferric oxide powder bin board plug valve and a ferric oxide powder bin rotating valve are mounted at the discharge hole of the ferric oxide powder bin; the discharge hole is further connected with a ferric oxide powder bagging machine; a section of air inlet pipeline is connected with the ferric oxide powder conveying pipeline which is connected with the lower part of the rotating furnace rotating valve at the discharge hole of the roasting furnace; an air inlet is formed in the wall of the air inlet pipeline; the air inlet pipeline is provided with a horizontal extension end; an air supplementing hole is formed in the axial end part of the horizontal extension end; a baffle is mounted on the air supplementing hole. The acid regeneration station ferric oxide powder cooling treatment system is reasonable in structural design and simple and convenient to operate, the cooling effect of ferric oxide powder can be improved, the high temperature resistance requirements of dust collection equipment can be effectively reduced, and the service life of equipment can be prolonged.

Owner:天津市腾源环保科技有限公司

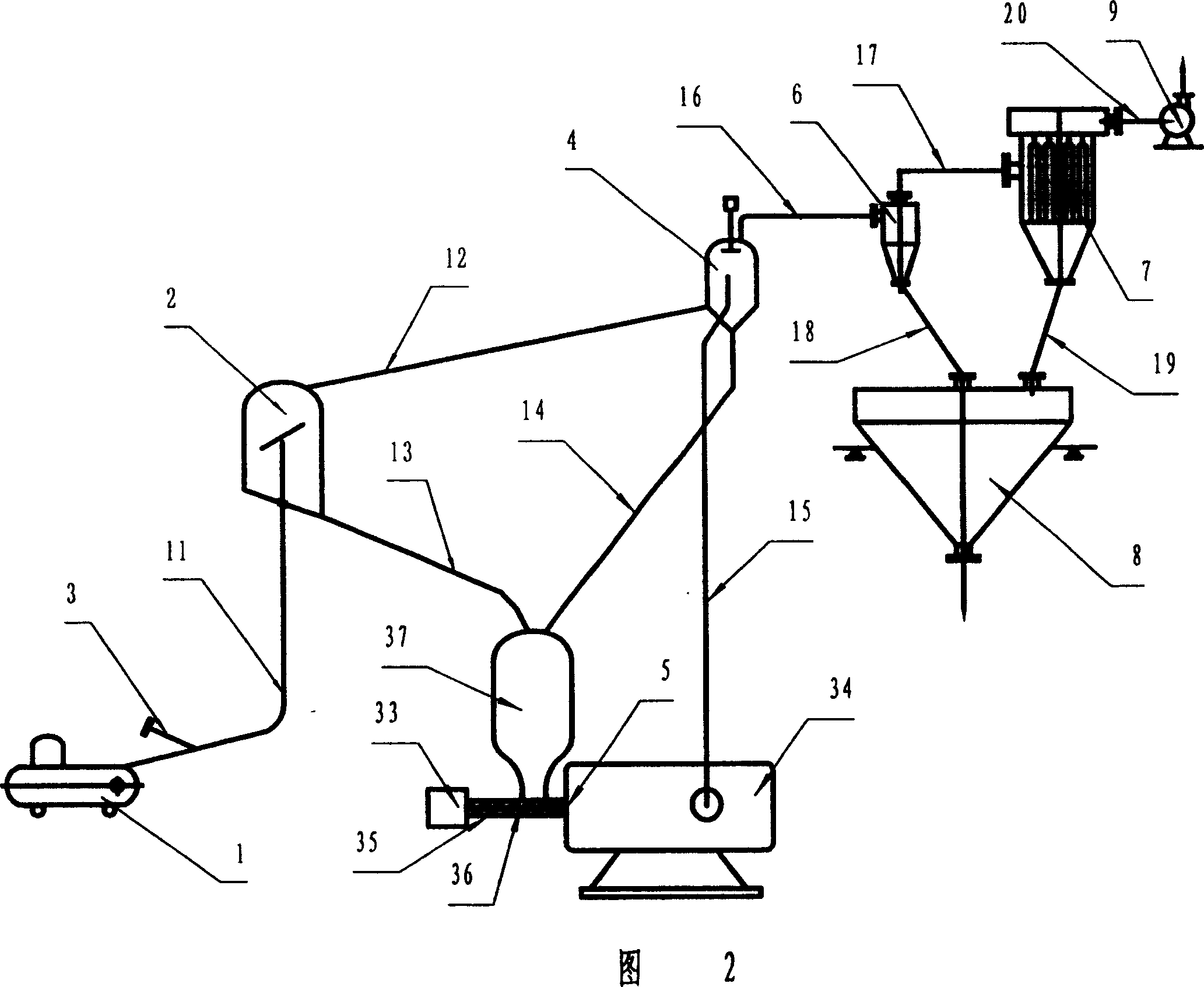

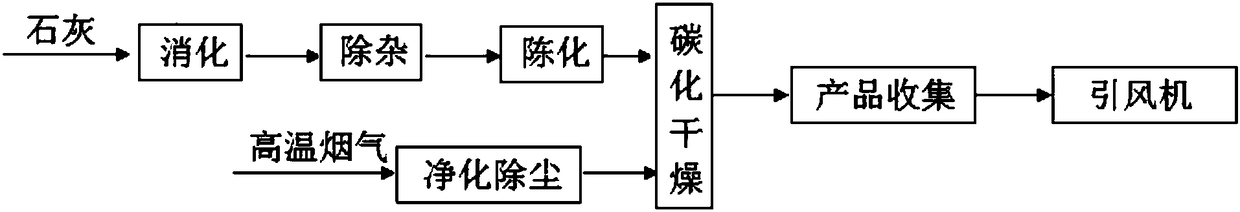

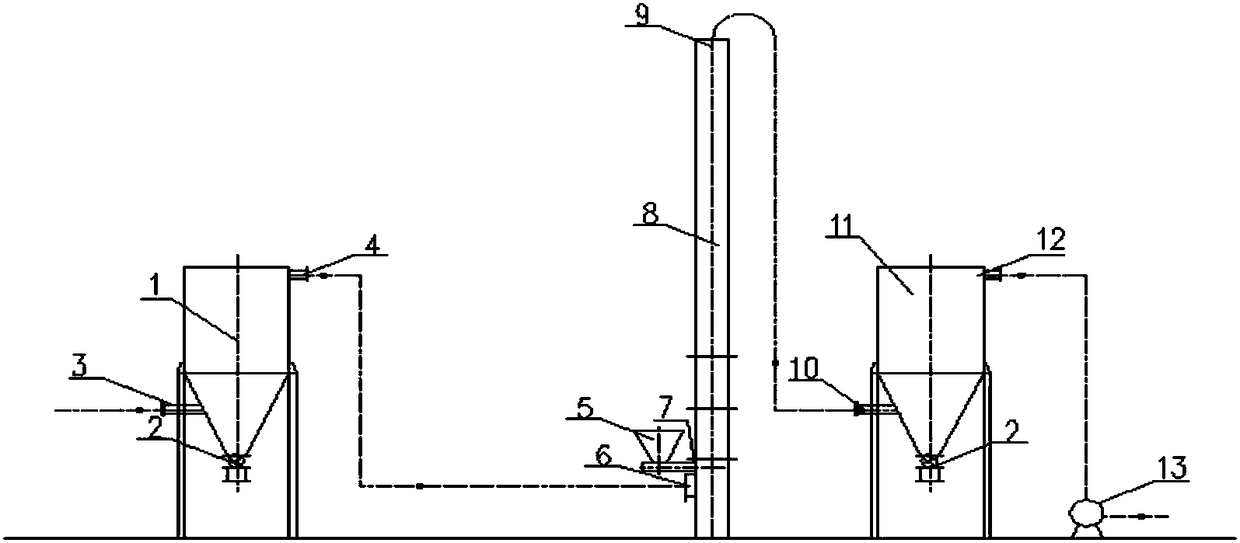

Production process and device for synthesizing calcium carbonate by carbonization and drying of high-temperature hot flue gas

ActiveCN105858699BReduce production energy consumptionLow costCalcium/strontium/barium carbonatesEnergy inputCarbonizationDust control

The invention discloses a production process and device for synthesizing calcium carbonate by carbonization and drying of high-temperature hot flue gas. The process includes: after the high-temperature hot flue gas from the kiln tail of a cement plant is dedusted by a flue gas purification and dust collector, the clean hot flue gas enters a reaction tower . The calcium hydroxide wet material is fed into the reaction tower from the feeder. The calcium hydroxide wet material and the hot flue gas in the reaction tower conduct mass transfer and heat transfer, complete the carbonization reaction and drying process, and finally obtain the calcium carbonate powder product. The dried calcium carbonate powder product enters the product collection dust collector along with the hot flue gas, and the gas-solid separation is realized in the product collection dust collector. The gas is discharged by the induced draft fan, and the sinking calcium carbonate powder product is collected by the product dust collector. The discharge valve at the lower end discharges. The invention utilizes the waste high-temperature hot flue gas at the kiln tail of the cement plant, which not only reduces the emission of greenhouse gases (CO2), but also makes full use of waste heat, and synthesizes high value-added chemical products through reaction and drying integration. The process flow is simple and there is no ash water. secondary pollution.

Owner:SINOMA INT ENG

A kind of method for preparing transition metal monoxide powder, target material and thin film

The invention provides methods for preparing transition metal monoxide powder, target material and film. The methods comprise the following steps: transition metal M powder and transition metal M oxide powder in a mole ratio being 1:1-1.2:1 are taken as reaction raw materials and sufficiently mixed with alkali halide with mass being 0.5-2.5 times, preferably, 0.5-2 times of the total mass of the reaction raw materials, the mixture is packaged in a reactor in a vacuum manner and reacts at 900-1,100 DEG C for 5-10 h, and the transition metal monoxide powder is obtained; the transition metal monoxide powder is subjected to spark plasma sintering, and the transition metal monoxide target material is obtained; a film grows on the transition metal monoxide target material, and the transition metal monoxide film is obtained. The transition metal monoxide powder, target material and film can be prepared rapidly at low temperature with the methods.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A Combined Turbine Structure with Hollow Nozzle Blades

ActiveCN111305910BRaise some intake airImprove energy conversion efficiencyStatorsNon-positive displacement enginesImpellerEngineering

The invention relates to a combined turbine structure with hollow nozzle blades, comprising at least one centripetal turbine and at least one stage of axial flow turbine arranged downstream of the centripetal turbine, the nozzle blades of the centripetal turbine are hollow structures , After the high-pressure air flow passes through the regulating valve set in the cylinder inlet passage, it first enters the centripetal turbine to do work, and the exhaust gas of the impeller turns and passes through the axial air flow channel of the nozzle blade to enter the downstream turbine to continue to do work. The invention adopts the centripetal impeller in the first stage, which can meet the design requirements of small volume flow and large enthalpy drop, rapidly reduce the temperature and pressure of the working medium, and easily realize the whole-circle air intake of the nozzle or increase the partial air intake of the nozzle, so as to Improve the aerodynamic efficiency of the turbine and reduce the exciting force of the air flow on the impeller; in addition, when the outlet gas of the centripetal turbine passes through the axial air flow channel, it can cool the nozzle blades and reduce the high temperature resistance requirements of the blade materials. Increase the service life of the blades.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

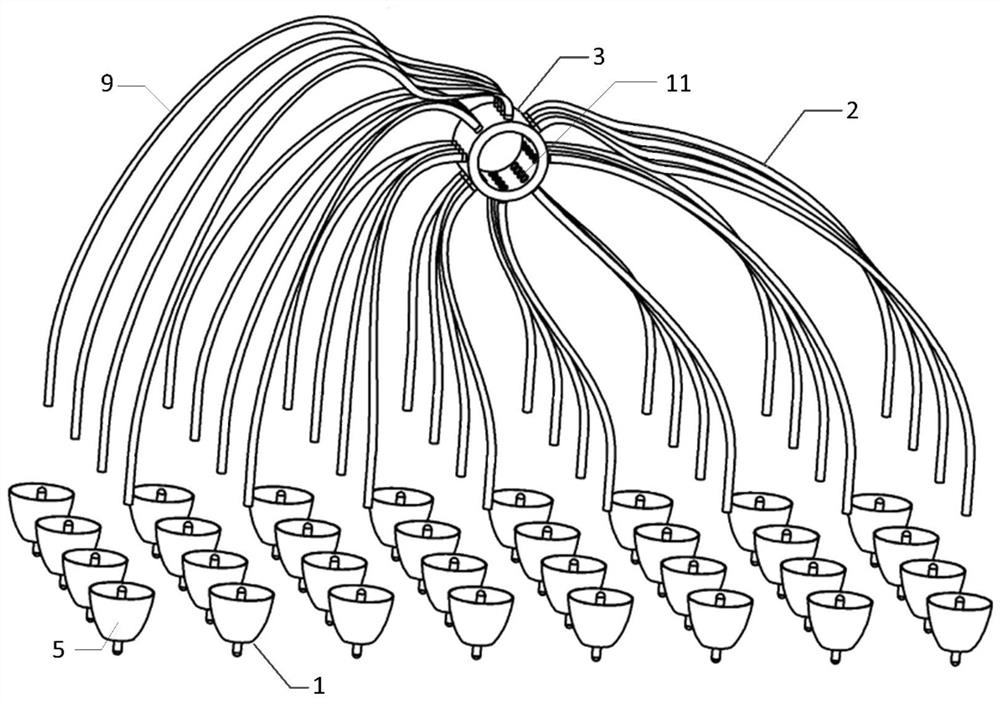

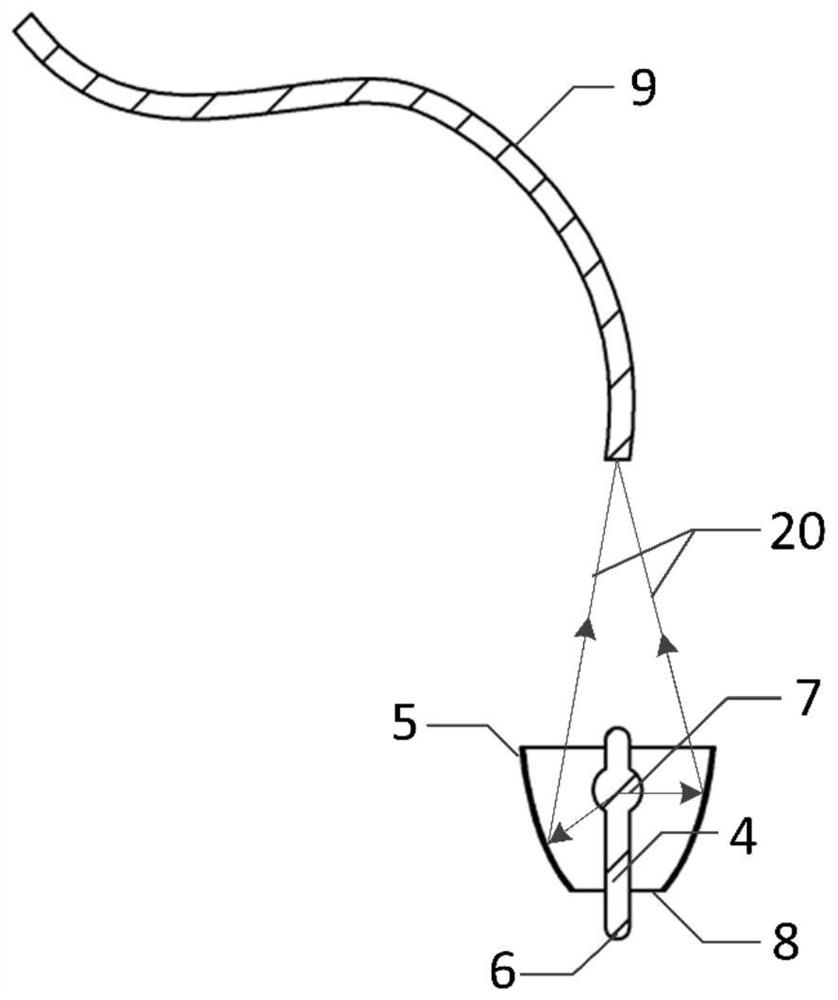

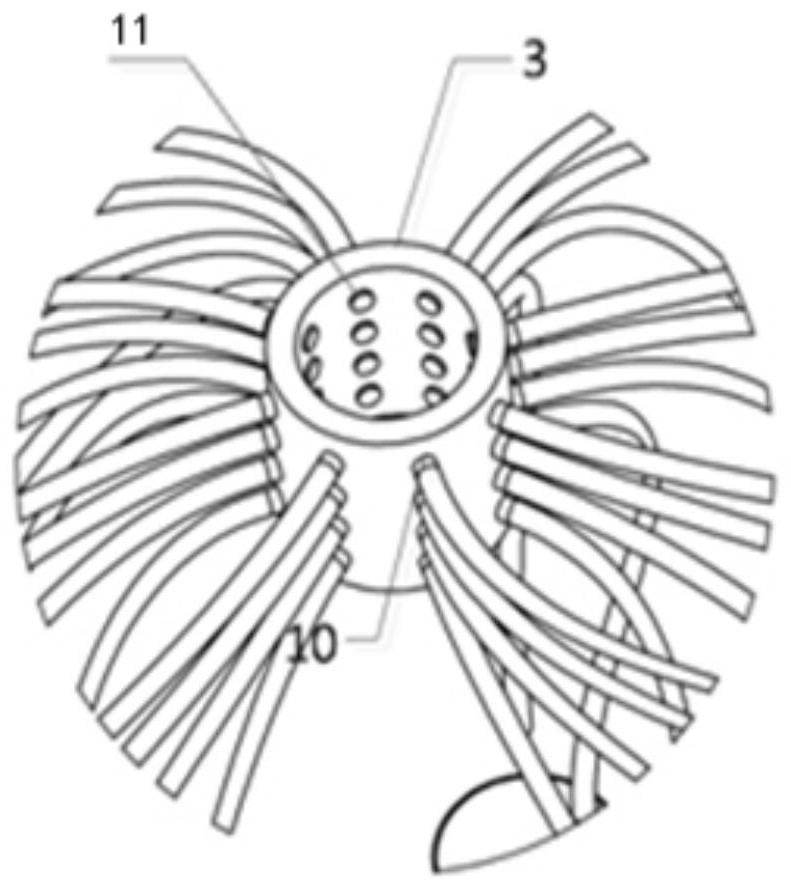

A device for simulating concentrated solar light heating

InactiveCN107249222BEvenly arrangedUniform Surface Light IntensityEducational modelsBundled fibre light guideFiberSolar light

The invention discloses a simulated condensation solar illumination heating device belonging to the field of illumination heating equipment. The device comprises a strong light source array, a fiber array and a heating cavity, wherein a spherical xenon short-arc lamp is used as an artificial light source, a light output end of the fiber array is arranged on the heating cavity through an installation hole array on the heating cavity, the fiber array is used as a transmission medium and is used for guiding light to the heating cavity, and the heating cavity is used for fixing an emergent direction of light and is used as an output end of light heater; and since the fiber array has flexibility characteristic, the heating cavity for fixing a fiber can move and rotate within a certain range so as to be adaptive to heated workpieces at different directions and facing different directions. The surface of a heated object is uniform in illumination intensity, heating temperature rising direction is uniform, and the practicability and the flexibility of a strong light heating cavity device during the application process are improved; and meanwhile, a heating region is isolated with a light source region, the high-temperature resistant requirement of a high-temperature heating cavity is reduced, and the light source is high in safety.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

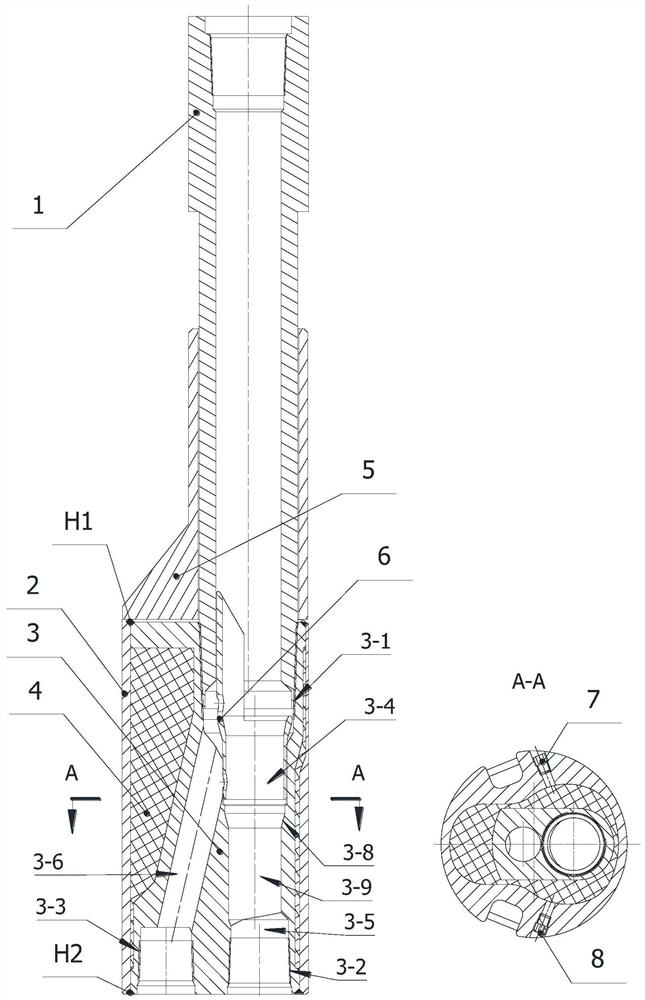

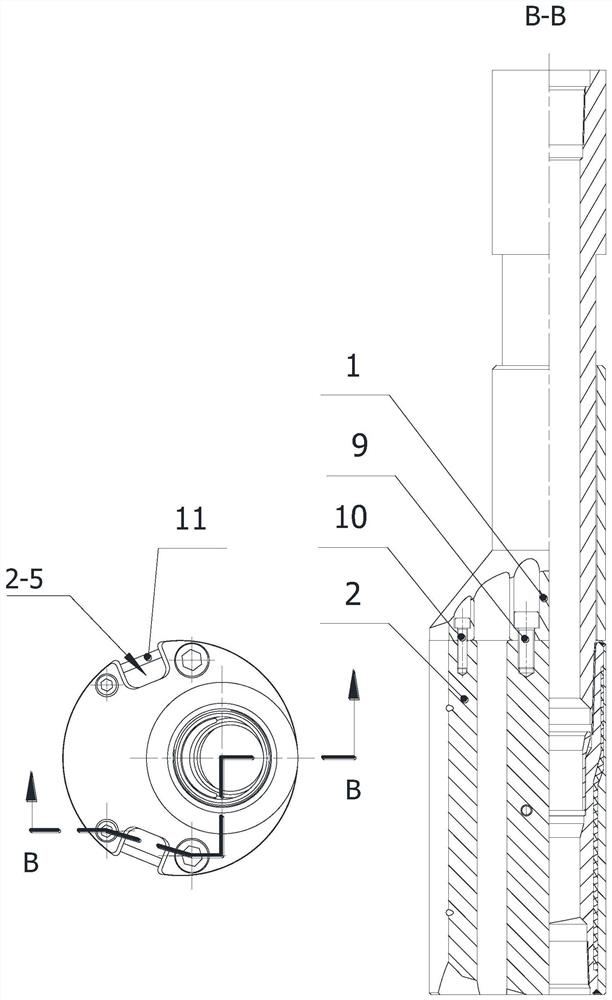

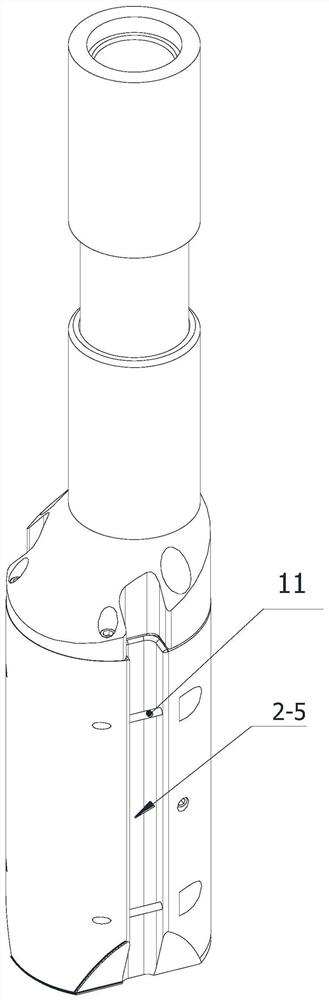

Thermal insulation straight hole injection-production Y joint and using method thereof

ActiveCN113356815ALow costReduce operating costsDrilling rodsGeothermal energy generationThermal insulationScrew thread

The invention provides a thermal insulation straight hole injection-production Y joint and a using method thereof. An inner core is arranged in a shell; the tail end of a lifting nipple extends into the shell and is in threaded connection with the inner wall of the head end of the inner core; an upper guiding shoe is installed at the head end of the shell, the tail end of the upper guiding shoe is fixedly welded to the head end of the inner core, and the tail end of the shell is fixedly welded to the tail end of the inner core; a filler cavity is formed between the inner wall of the shell and the outer wall of the inner core, and a filler is filled in the filler cavity. The tool can realize internal and external heat insulation in a steam injection process, provides an internal steel wire or cable operation channel, and can be matched with a production blanking plug to carry out oil extraction production.

Owner:CNOOC ENERGY TECH & SERVICES

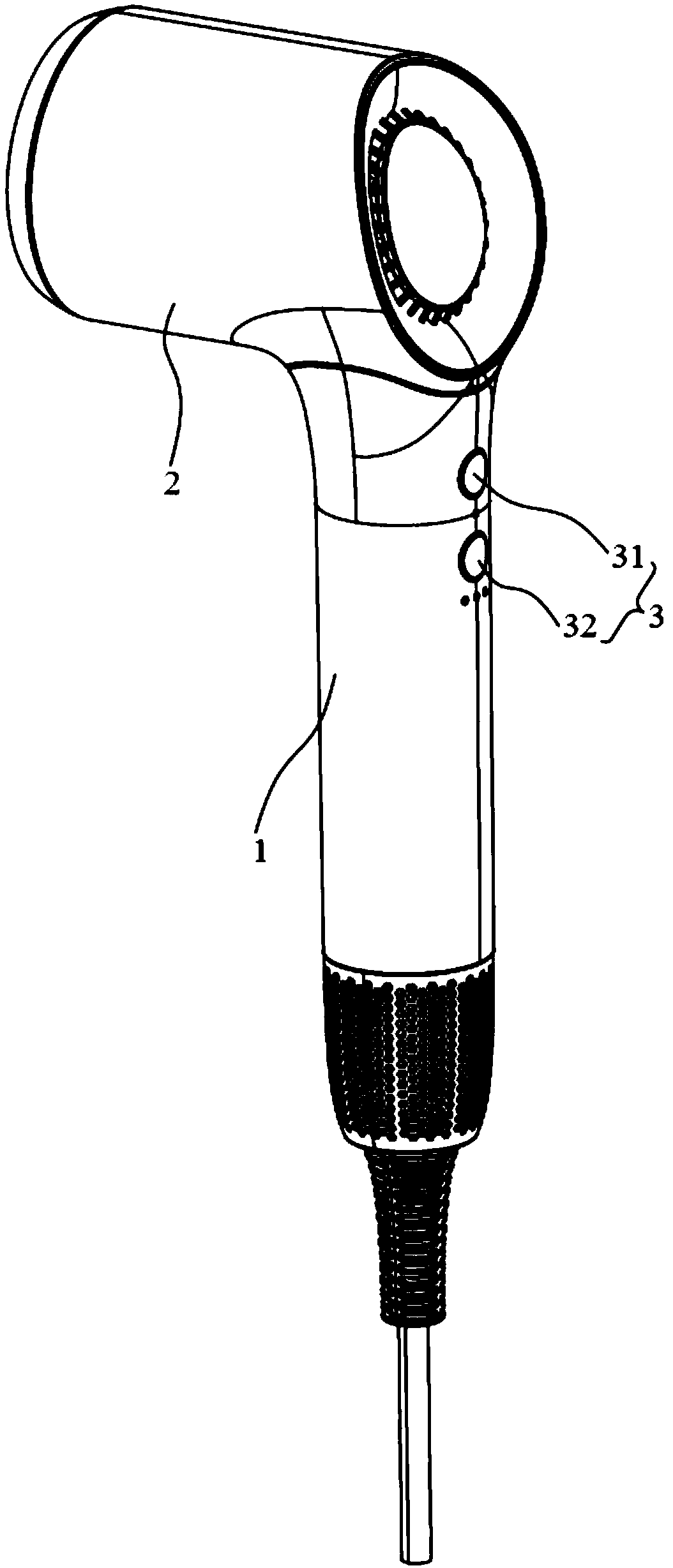

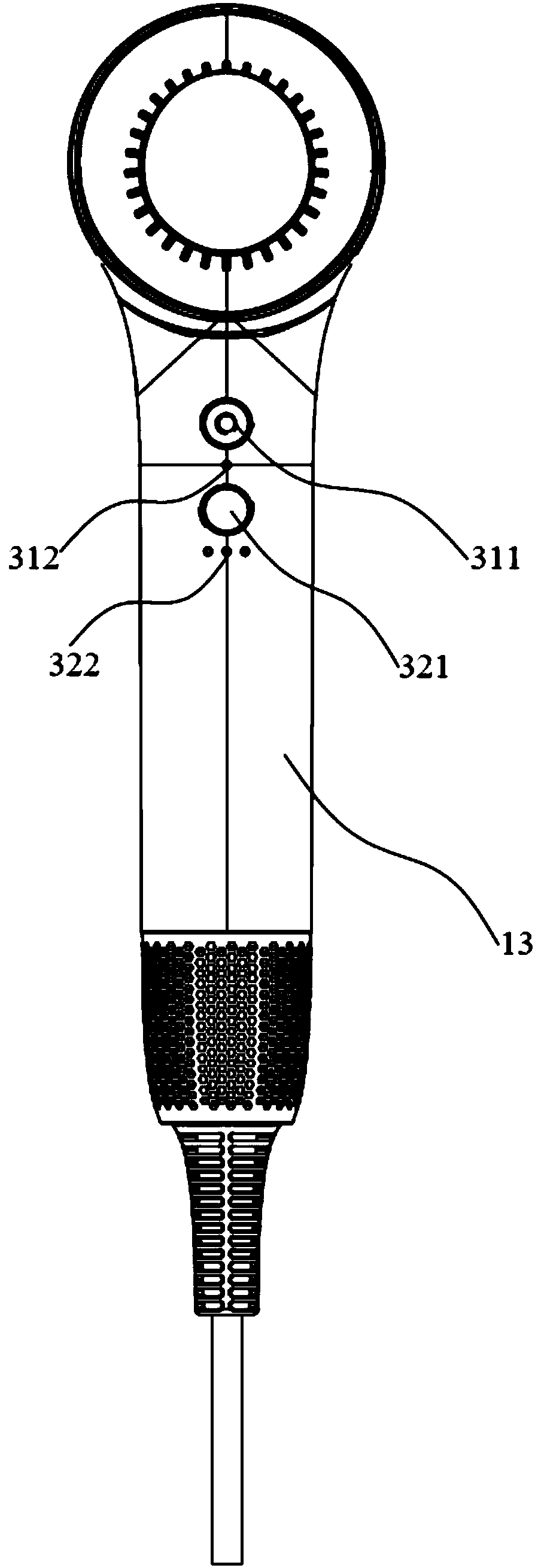

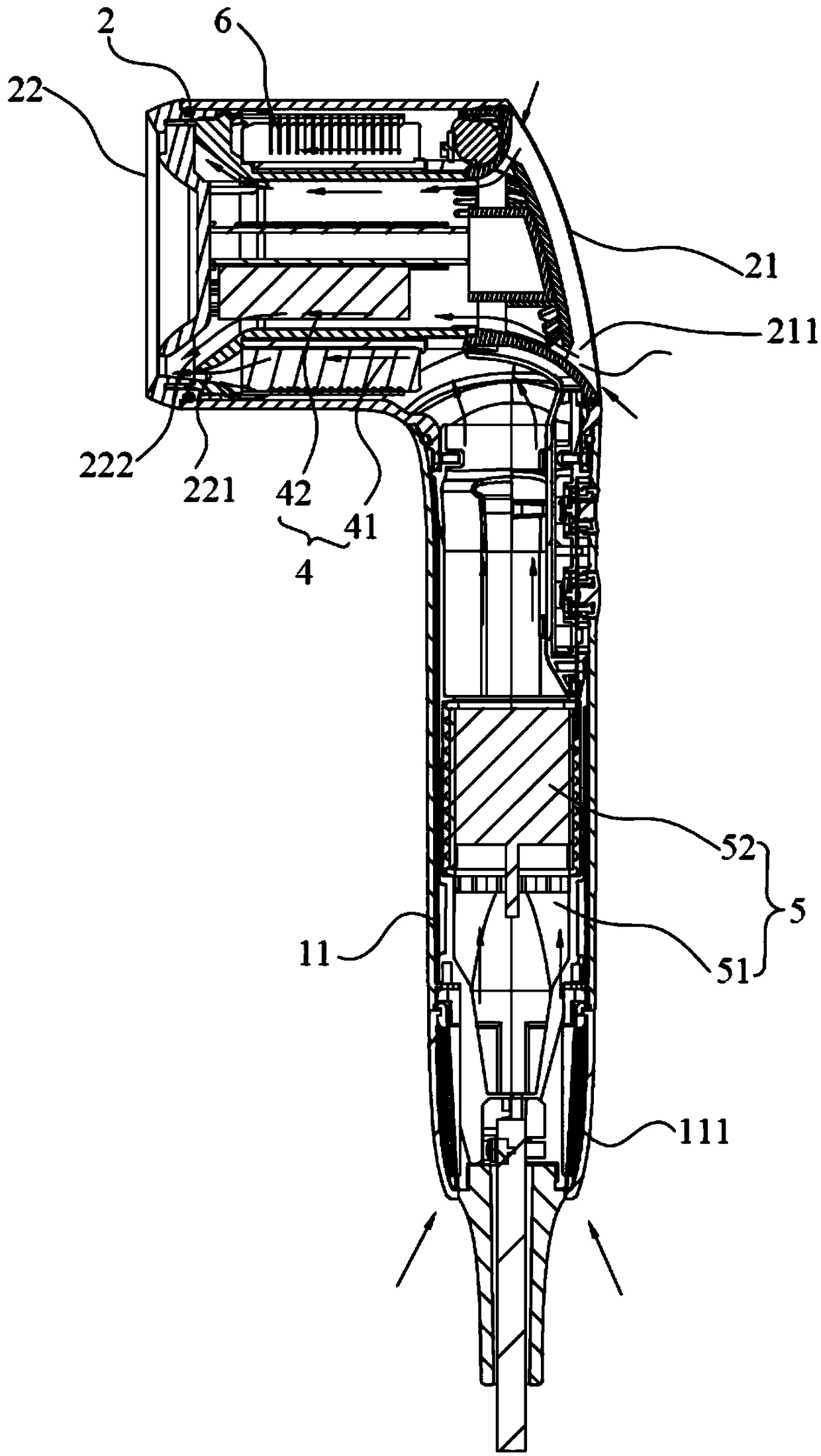

Hair drying device

The invention belongs to the technical field of handheld appliances and particularly relates to a hair drying device. The hair drying device comprises a handle, a device body and a switch assembly. The switch assembly is arranged on the handle and located at the side, away from a second end, of the handle in the extension direction of the device body, in this way, a user can operate the switch assembly when holding the handle by hand, for example, the right hand of the user holds the handle, the user operates the switch assembly through the thumb, so that single-hand operation is achieved, andthe product experience of the user is improved. In addition, in the extension direction of the device body, the switch assembly is located at the side, away from the second end, of the handle and isaway from a fluid outlet, the influence of a high-temperature fluid medium flowing out from the fluid outlet to the switch assembly is avoided, the demand of the switch assembly for high temperature resistance is reduced, and accordingly the cost of the switch assembly is correspondingly reduced.

Owner:SHENZHEN SOOCAS TECH CO LTD

Steam turbine and method for reducing operating temperature of outer cylinder of steam turbine

InactiveCN109026202AReduce high temperature requirementsLow costMachines/enginesEngine componentsOperating temperatureReturn channel

The invention discloses a steam turbine and a method for reducing the operating temperature of an outer cylinder of the steam turbine. A high temperature steam outlet channel and a low temperature steam return channel are arranged between the front end steam sealing interval and the back end through flow stage of the steam turbine, a steam inlet of the high temperature steam outlet channel is formed in a steam sealing body on the front end steam sealing interval, and a steam outlet of the high temperature steam outlet channel is formed in the back end through flow stage; and a steam inlet of the low temperature steam return channel is formed in the back end through flow stage, located on the inner side of the steam outlet of the high temperature steam outlet channel, and separated by morethan one through flow stage, and the steam outlet of the low temperature steam return channel is formed in the steam sealing body of the front end steam sealing interval, located on the outer side ofthe steam inlet of the high temperature steam outlet channel, and separated by more than one ring of steam sealing body. The outer cylinder no longer bears the higher operating temperature and can bemade from the low-grade materials, the requirements of the resistance to high temperature of the outer cylinder are reduced, the costs of production and manufacturing are greatly reduced accordingly,and the high economic benefits are achieved.

Owner:DONGFANG TURBINE CO LTD

Yttrium cathode for magnetron tungsten of microwave oven and preparation process thereof

ActiveCN102800542BSolve the radiationReduce high temperature requirementsTransit-tube cathodesManufacturing cost reductionMicrowave oven

The invention discloses a tungsten yttrium cathode for a magnetron of a microwave oven. The tungsten yttrium cathode is characterized by comprising the following components in percentage by weight: 0.3 to 3 percent of yttrium, and the balance of tungsten. The invention also discloses a preparation process for the tungsten yttrium cathode for the magnetron of the microwave oven. The tungsten yttrium cathode has brittleness and high temperature performance of products, enhances the plasticity of the products, has good working performance, high plasticity, low production cost and no radiation, reaches the same working effect and greatly reduces the working temperature, so that the tungsten yttrium cathode can greatly reduce the requirements of high temperature resistance of electrode metal materials, meets the requirements on environmental protection, and obviously reduces the manufacturing cost at the same time.

Owner:佛山宁宇科技股份有限公司

System for monitoring pressure vessel of reactor of nuclear power station and method thereof

ActiveCN102496393BLow costLow cost controlNuclear energy generationNuclear monitoringElectricityContact high

Owner:中广核工程有限公司 +1

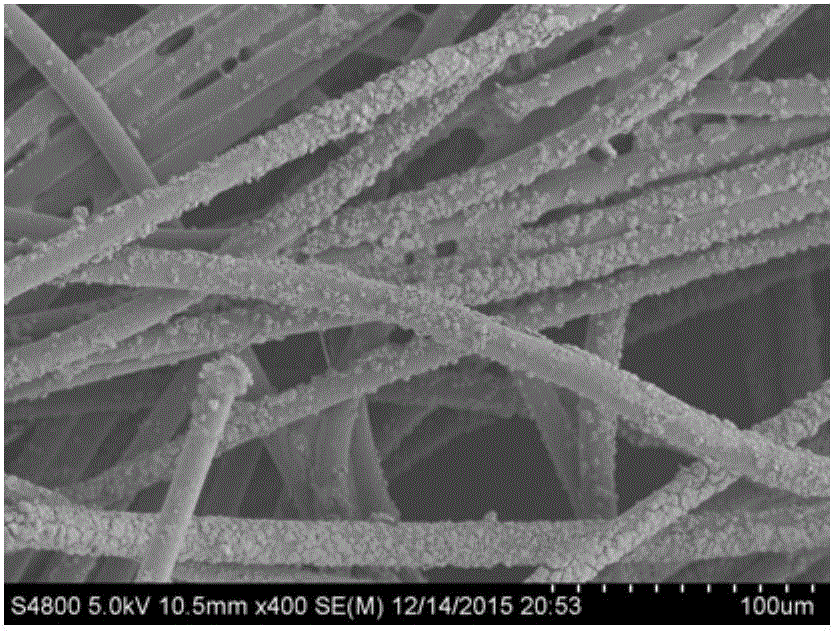

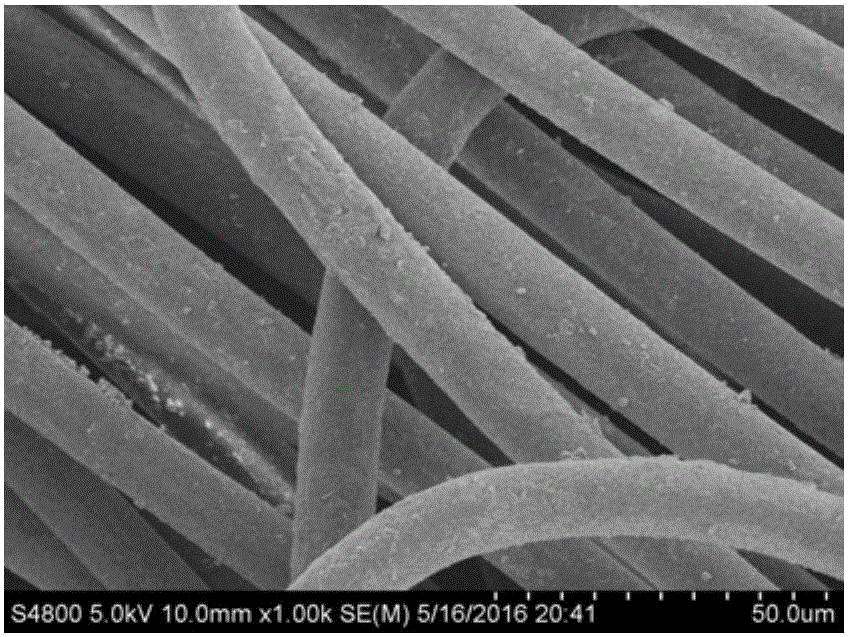

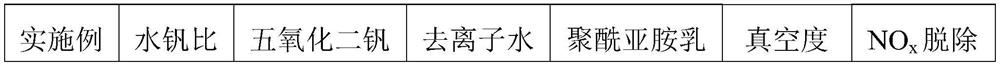

Preparation method of low-temperature denitration filter material based on water quenching process

ActiveCN112546748AImprove stabilityHigh load rateDispersed particle filtrationMetal/metal-oxides/metal-hydroxide catalystsEmulsionVanadium(V) oxide

The invention relates to the technical field of purification of industrial boiler flue gas, in particular to a preparation method of a low-temperature denitration filter material based on a water quenching process. The preparation method comprises the following steps: uniformly mixing and stirring vanadium pentoxide powder, an organic modifier and cerous nitrate hexahydrate powder to prepare a low-temperature denitration catalyst precursor emulsion; adding the low-temperature denitration catalyst precursor emulsion into a reaction kettle, and soaking filter cloth in a reaction kettle in vacuum; and finally, drying the soaked filter cloth, and carrying out medium-temperature calcination to obtain the low-temperature denitration filter material. A preparation method of the low-temperature denitration catalyst precursor emulsion comprises the following steps: adding deionized water into the reaction kettle, heating and melting vanadium pentoxide powder, quickly pouring the molten vanadiumpentoxide powder into the deionized water, and conducting ultrasonic stirring and dissolving; adding an organic modifier into the solution, and performing full stirring and uniform mixing to obtain astable vanadium pentoxide emulsion; and finally, adding cerous nitrate hexahydrate powder into the solution, and conducting stirring until the cerous nitrate hexahydrate powder is completely dissolved to obtain the low-temperature denitration catalyst precursor emulsion.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com