Test bench with double combustion chambers, double superchargers and low cycle fatigue based on self-circulation mode

A double combustion chamber, double supercharger technology, applied in the field of power machinery, can solve the problems of high temperature resistance of flow distribution valve, change of mechanical load and heat load, and failure of two superchargers, etc., to achieve easy adjustment and control , reduce dependence and consumption, reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

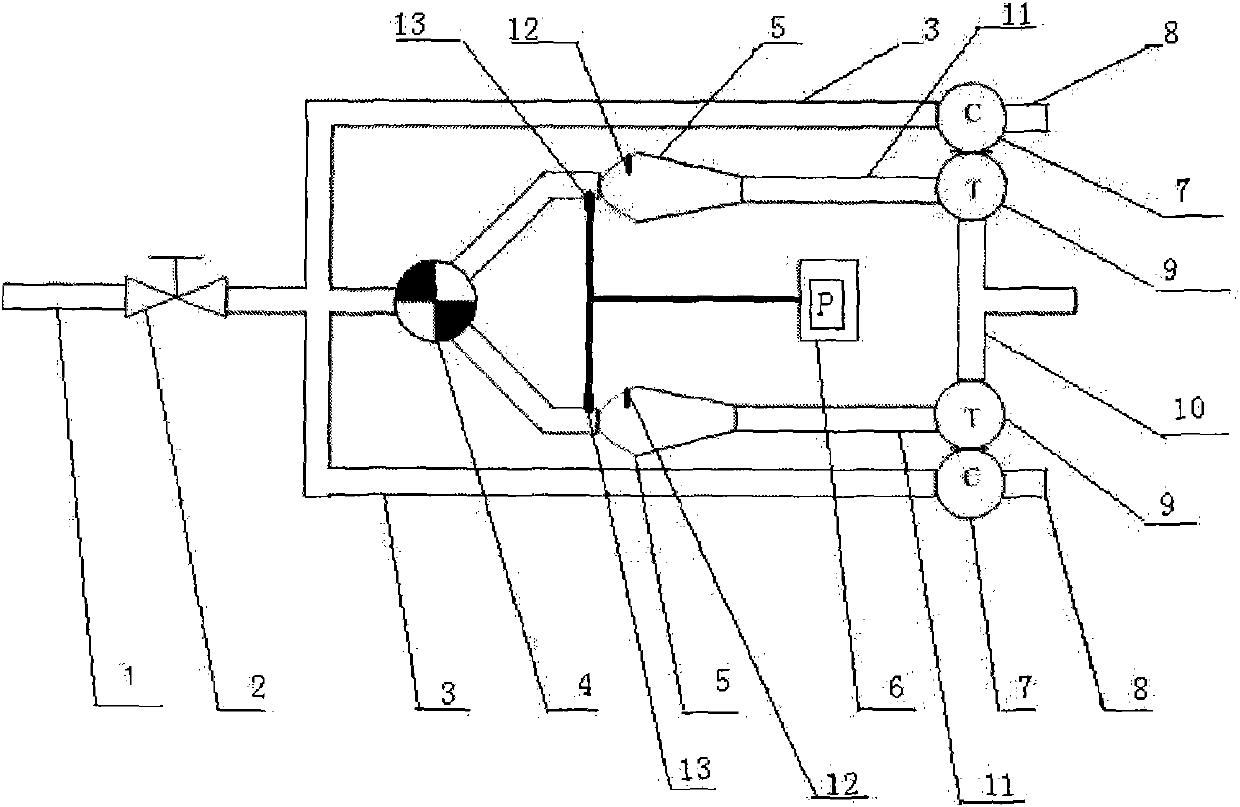

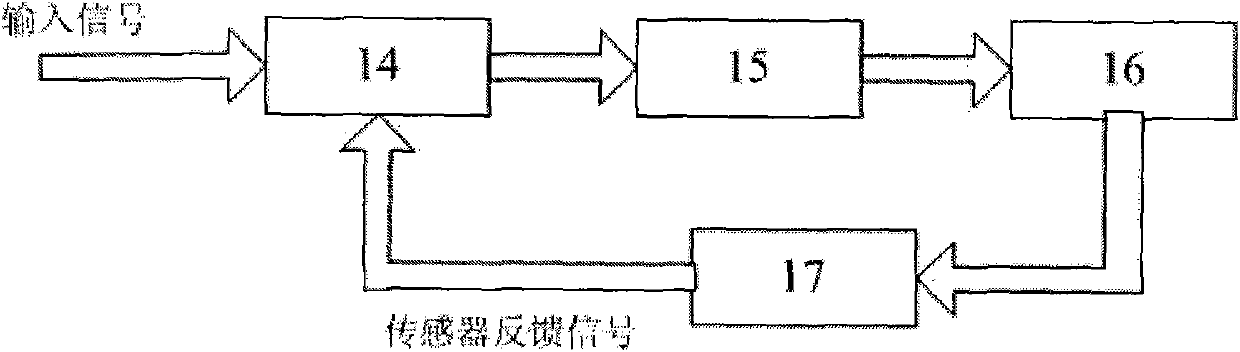

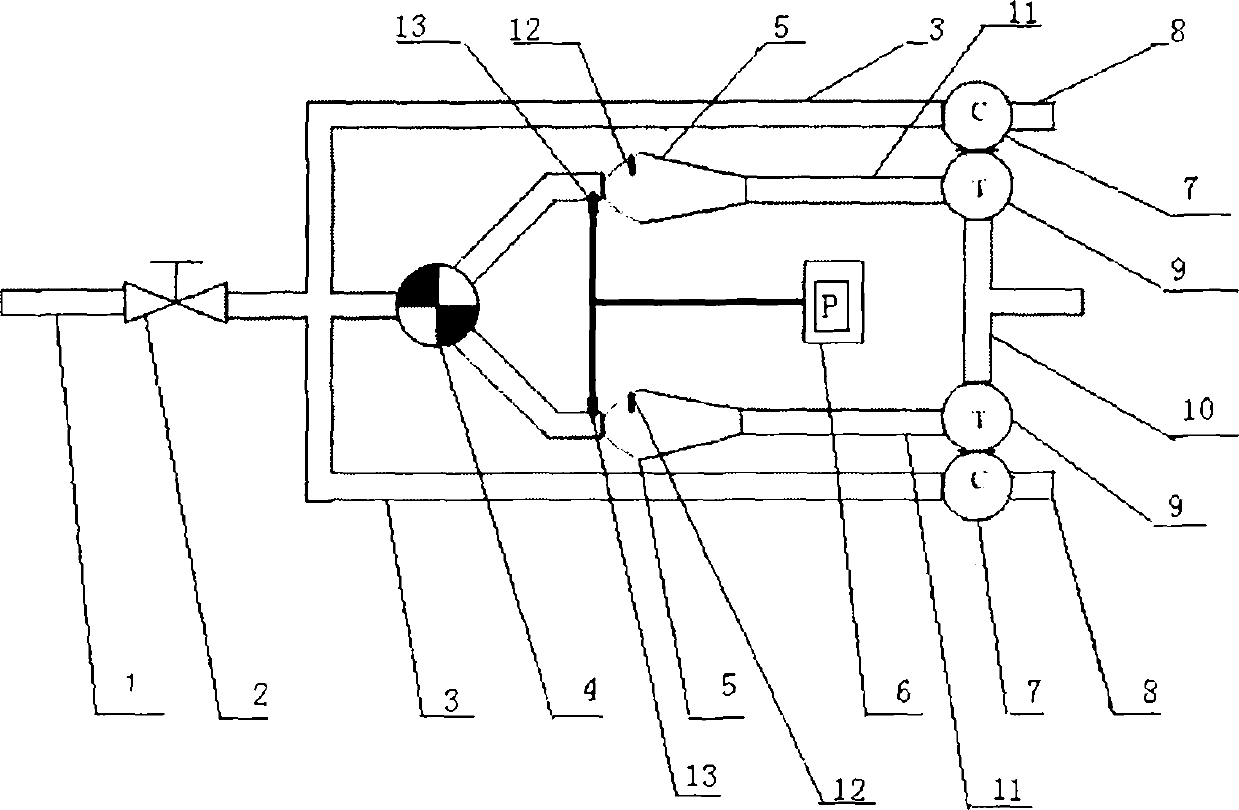

[0027] Such as figure 1As shown, the test bench of the present invention comprises: external air source inlet valve 2, supercharger compressor outlet pipeline 3, combustor intake flow distribution valve 4, two combustors 5, fuel supply system (fuel tank and oil pump 6. Solenoid valve oil injection device 13), supercharger compressor inlet pipeline 8, supercharger turbine outlet pipeline 10, supercharger turbine inlet pipeline 11. Among them, the intake air flow distribution valve of the combustion chamber adopts electronic control technology, figure 2 It is a block diagram of the electric control system, which mainly includes a controller 14 , a motor 15 , a valve mechanical actuator 16 , and a valve position sensor 17 .

[0028] Compared with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com