A kind of rubber powder modified asphalt linking agent and preparation method thereof

A technology of modified asphalt and connecting agent, used in building components, building insulation materials, construction and other directions, can solve the problems of not fully exerting the performance advantages of rubber powder modified asphalt mixture, and achieve the promotion of large-scale popularization and application. Economic prospects, the effect of improving road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

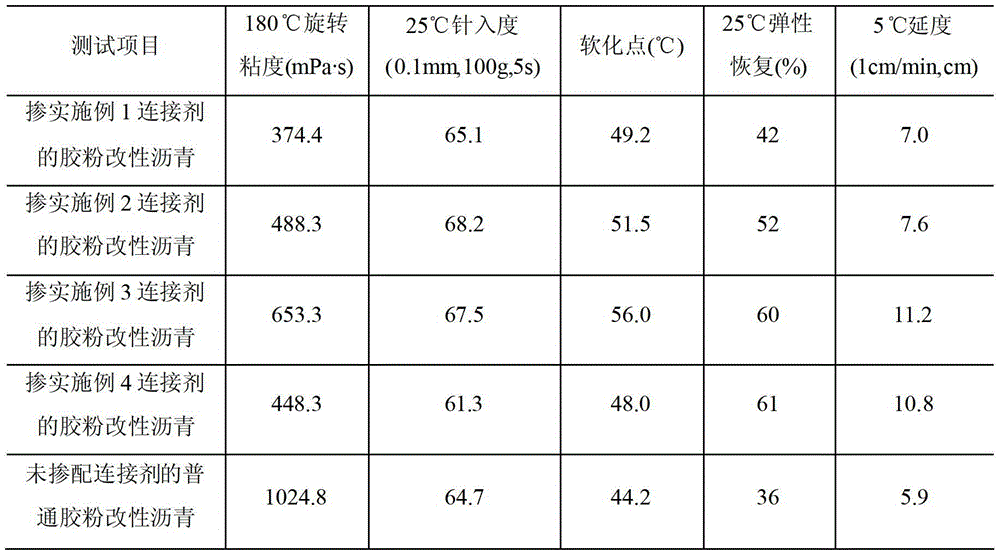

Examples

Embodiment 1

[0015] The linking agent is proportioned in parts by mass: 80 parts of deionized water, 14.8 parts of styrene, 3.7 parts of acrylamide monomer, 0.75 parts of potassium persulfate, and 0.75 parts of AEC10Na.

[0016] Preparation method: Take deionized water, AEC10Na, acrylamide monomer, styrene and potassium persulfate in order and put them into the reaction kettle in sequence; stir evenly, electric stirring speed is 120r / min, heat in a water bath at 70°C, and react continuously for 7h to obtain Uniform polymer emulsion; remove moisture and unreacted monomers in the copolymer emulsion, and dry to constant weight to obtain rubber powder modified asphalt binder.

Embodiment 2

[0018] The linking agent is proportioned in parts by mass: 80 parts of deionized water, 14.5 parts of styrene, 4.0 parts of N-methylolacrylamide monomer, 0.75 parts of sodium persulfate, and 0.75 parts of AEC10Na.

[0019] Preparation method: Take deionized water, AEC10Na, N-methylolacrylamide monomer, styrene and sodium persulfate in order and put them into the reaction kettle in sequence; stir evenly, electric stirring speed 80r / min, heat in a water bath at 65°C, Continue the reaction for 5 hours to obtain a uniform polymer emulsion; remove the moisture and unreacted monomers in the copolymer emulsion, and dry to constant weight to obtain the rubber powder modified asphalt binder.

Embodiment 3

[0021] The linking agent is proportioned in parts by mass: 78 parts of deionized water, 13 parts of styrene, 7 parts of N-methylolacrylamide monomer, and 1 part of sodium persulfate.

[0022] Preparation method: Take deionized water, N-methylolacrylamide monomer, styrene and sodium persulfate in order and put them into the reaction kettle in sequence; stir evenly, the electric stirring speed is 180r / min, heat in a water bath at 70°C, and continue the reaction After 7 hours, a uniform polymer emulsion was obtained; water and unreacted monomers in the copolymer emulsion were removed, and dried to a constant weight to obtain a rubber powder modified asphalt binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com