Flexible quasi-SIOx thin film growth device

A silicon oxide-like, thin film growth technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of inability to meet thin film growth, high risk, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

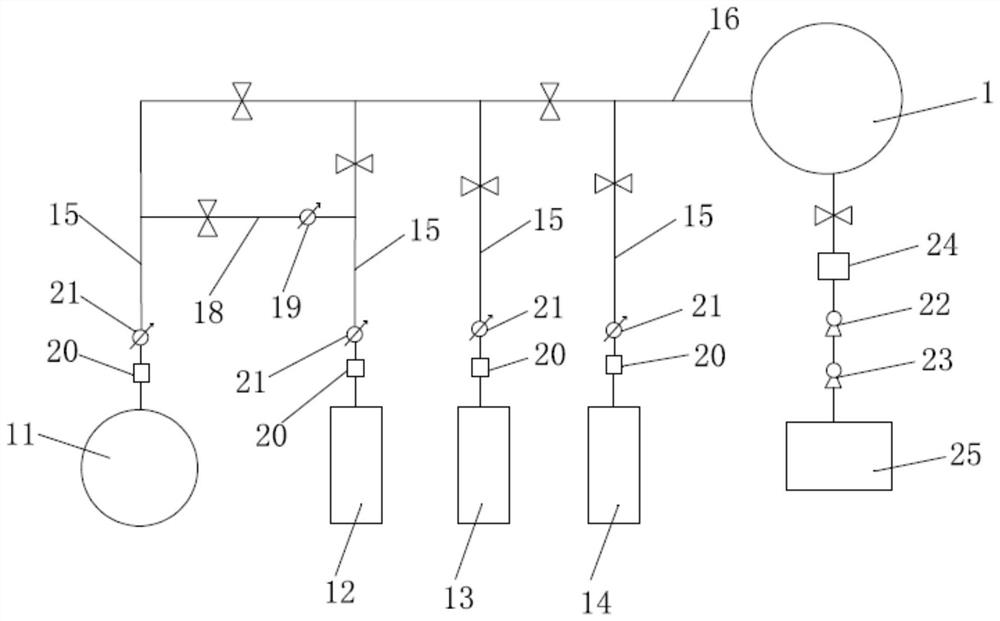

[0033] The invention provides a flexible silicon oxide film growth device, such as figure 1 As shown, it includes a reaction chamber 1 and a gas system connected to the reaction chamber 1, a control system, a vacuum system and an exhaust gas treatment system.

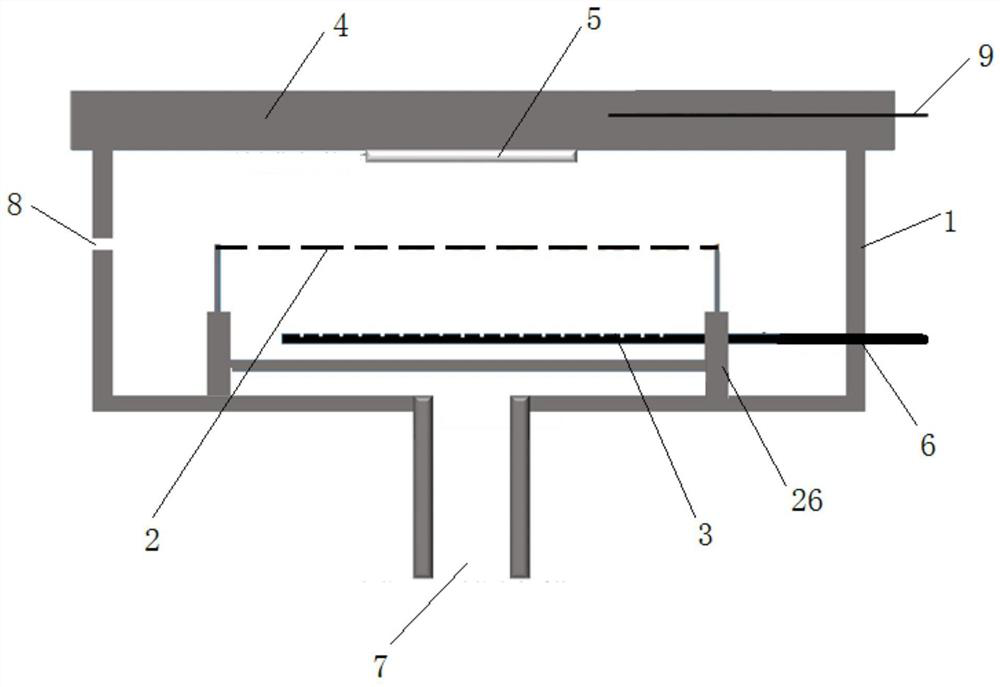

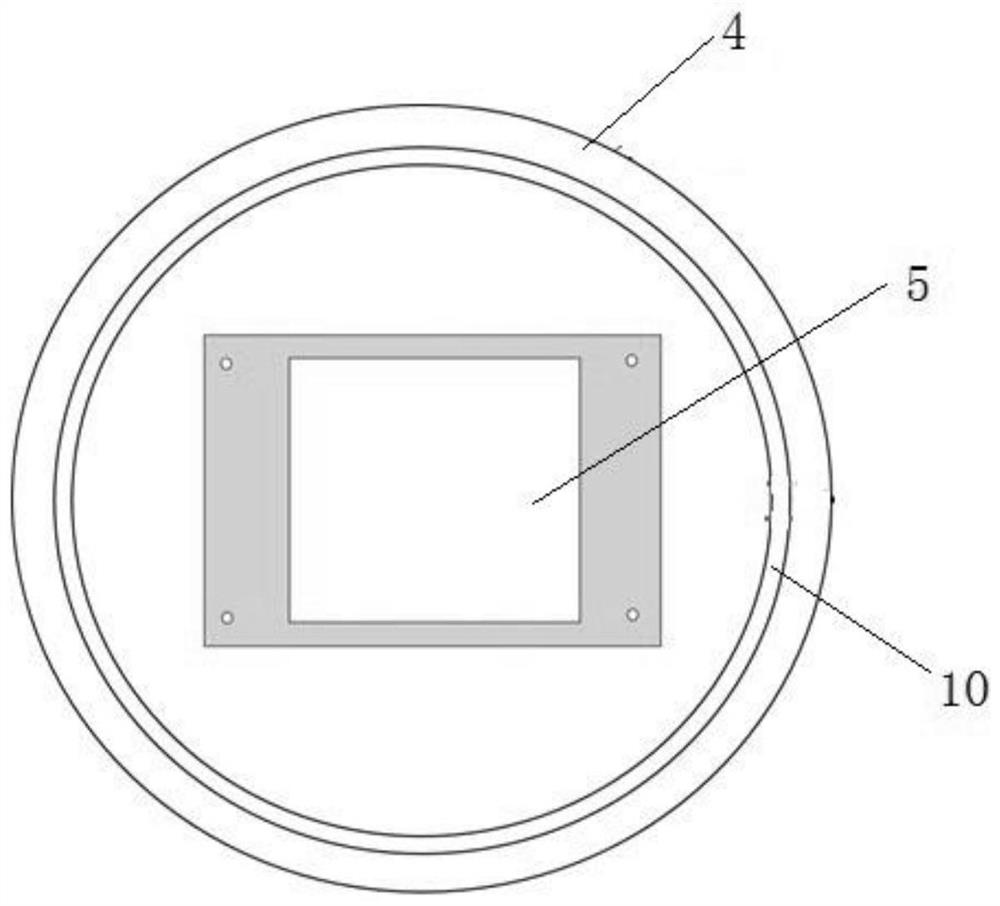

[0034] Such as figure 2 As shown, the radio frequency electrode 2 is suspended horizontally inside the reaction chamber 1, and the radio frequency electrode 2 is connected to the positive pole of the radio frequency power supply, and the reaction chamber 1 is connected to the negative pole of the radio frequency power supply; a gas mixer 3 is arranged under the radio frequency electrode 2, and the A substrate 5 for depositing thin films is fixed on the inside of the top cover 4, and the front side of the substrate 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com