Device for preventing generation of dioxin in refuse burning device

A waste incineration and generation device technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of slow cooling speed and synthesis of dioxins in flue gas, so as to prevent regeneration and reduce the probability of resynthesis , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

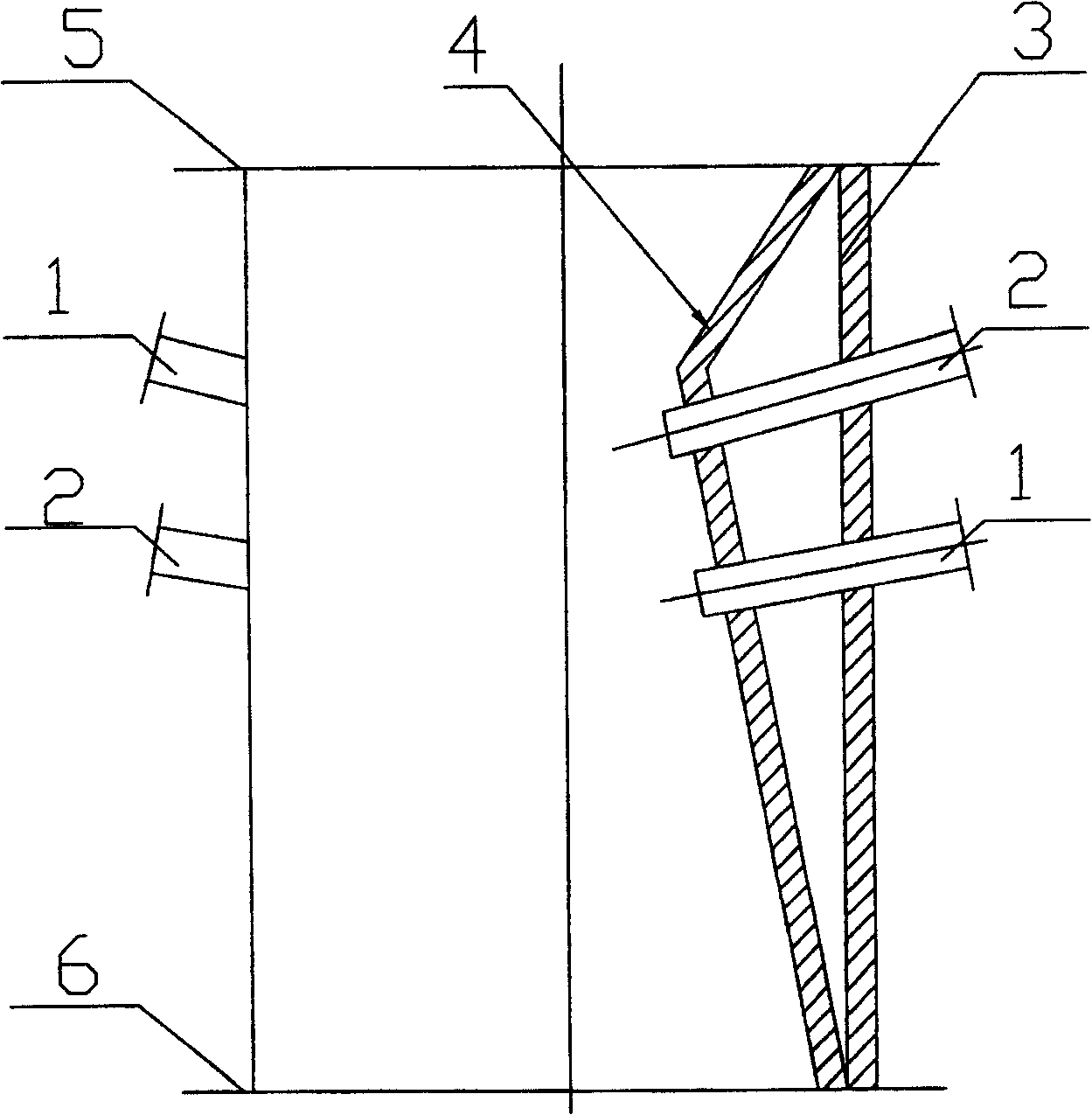

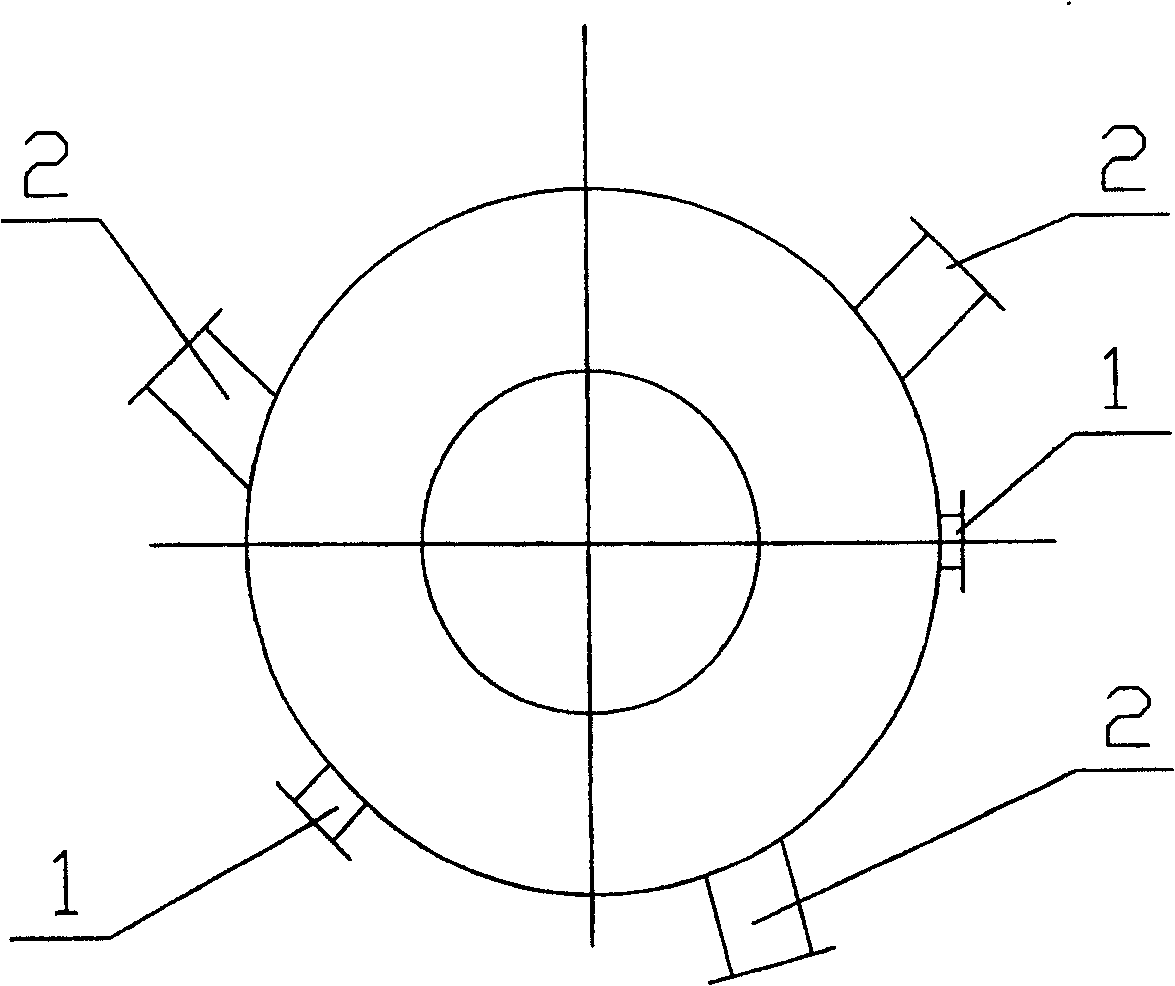

[0012] The device for preventing dioxin generation in the garbage incineration equipment of the present invention is to connect the constricted pipe in series to the flue gas discharge pipe of the second combustion chamber, which can accelerate the airflow. The upper end of the constricted pipe is formed with a flange 5, and the lower end is formed with a Lan 6, to communicate with the flue gas pipeline and the spray tower respectively; the necking pipe is a double-layer structure, the inner layer is the necking pipe 4, and the outer layer is a straight tube with the same diameter as the flue gas discharge pipe of the second combustion chamber Pipe 3, the effect of straight bobbin pipe 3 one is to prevent the constricted neck position of constricted pipeline 4 from being bent easily, and the 2nd, appearance is attractive in appearance. The necking pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com