Ejector and gas stove provided with ejector

An ejector and gas stove technology, applied in the field of ejectors, can solve problems such as affecting the smooth passage of gas, affecting the thermal efficiency of the gas stove, gas turbulence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

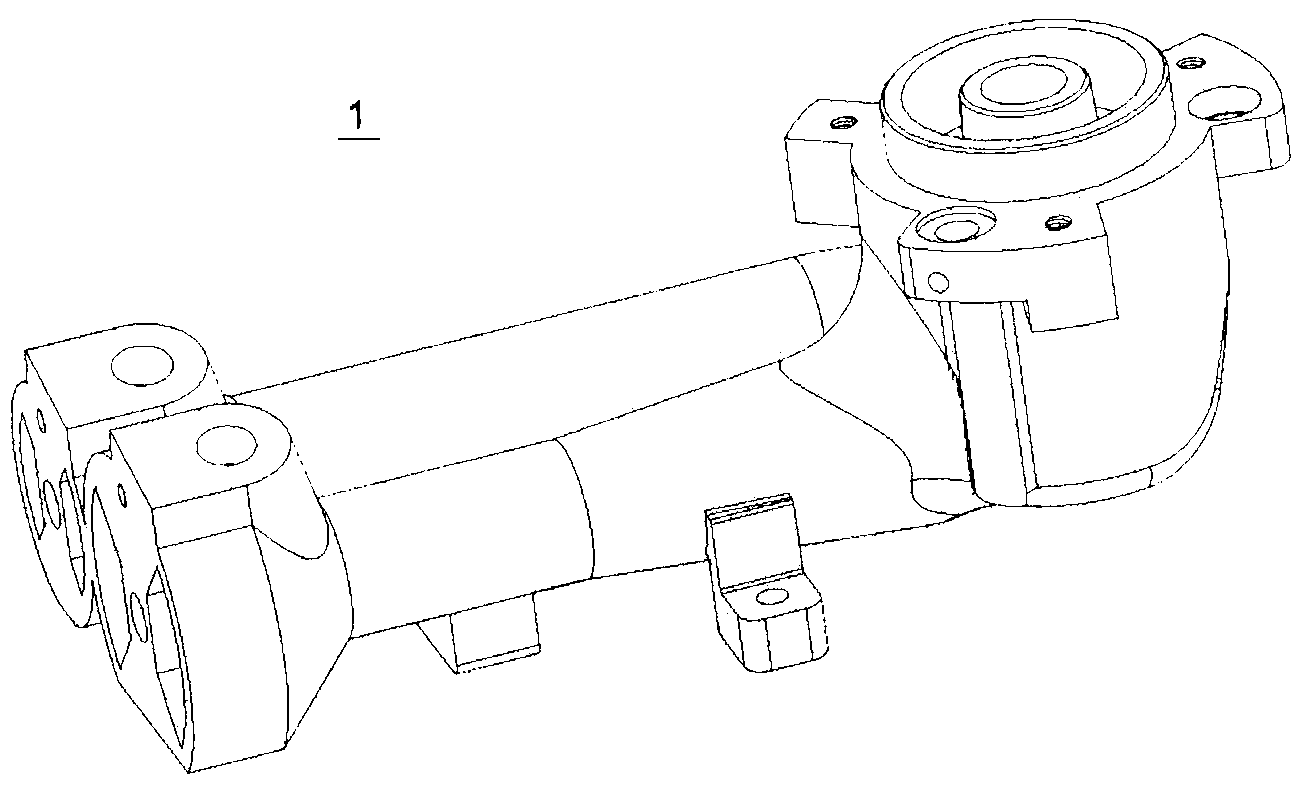

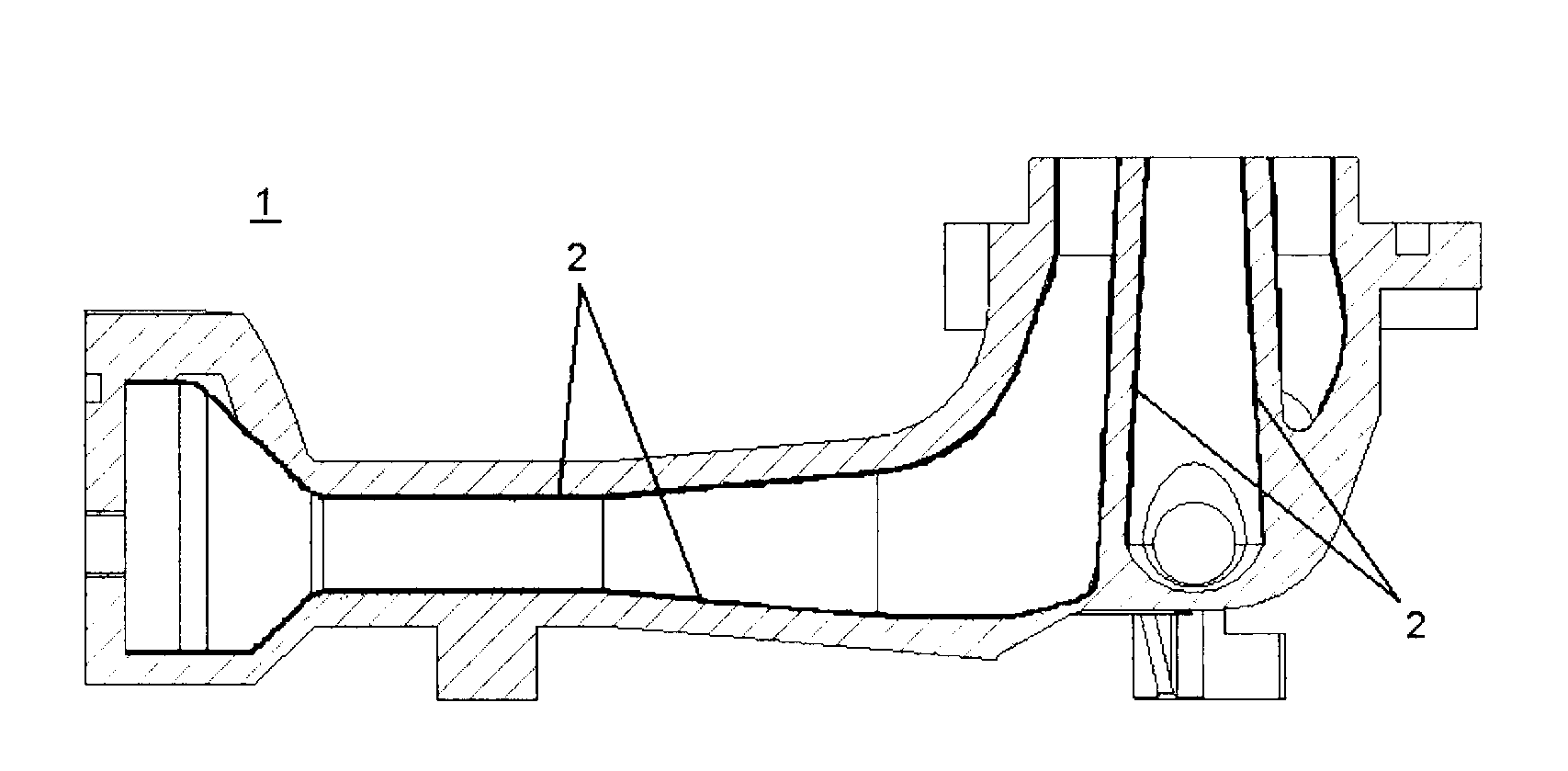

[0024] The ejector 1 embodiment that the present invention proposes, as figure 1 and 2 As shown, the ejector 1 is a double-pipe ejector, and the two pipes supply gas to the inner ring fire and the outer ring fire respectively. The specific manufacturing process of this embodiment of the ejector 1 is as follows: the main part of the ejector 1 is formed by casting molten iron, and then a layer of high-temperature-resistant and smooth-surfaced coating 2 is provided on all the inner walls of the ejector 1 . In the present embodiment, coating 2 is an enamel layer. Due to the setting of the enamel layer, the originally very rough inner wall of the injector 1 becomes relatively smooth.

[0025] The above are only preferred embodiments of the present invention, and other embodiments can be obtained by modifying or replacing certain technical features. For example, it is also possible to provide a high temperature resistant and smooth coating on only a part of the inner wall of the ...

Embodiment 2

[0027] The present invention also proposes an embodiment of a gas stove, which is provided with a burner and an injector. The inner wall of the ejector is partially provided with a high temperature resistant and smooth surface coating. The so-called "partially provided" means that no coating is provided on the inner wall of the injector near the burner. In this way, the high temperature resistance requirement of the coating can be reduced to a certain extent, thereby reducing the manufacturing cost. Specifically, the material of the coating is high temperature resistant paint. The inner wall of the ejector is provided with streamlined protrusions. In addition, a heat insulating device is arranged between the ejector and the burner, so that the requirement for high temperature resistance of the coating can be reduced to a certain extent, thereby reducing the manufacturing cost. Specifically, the heat insulation device is made of heat insulating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com