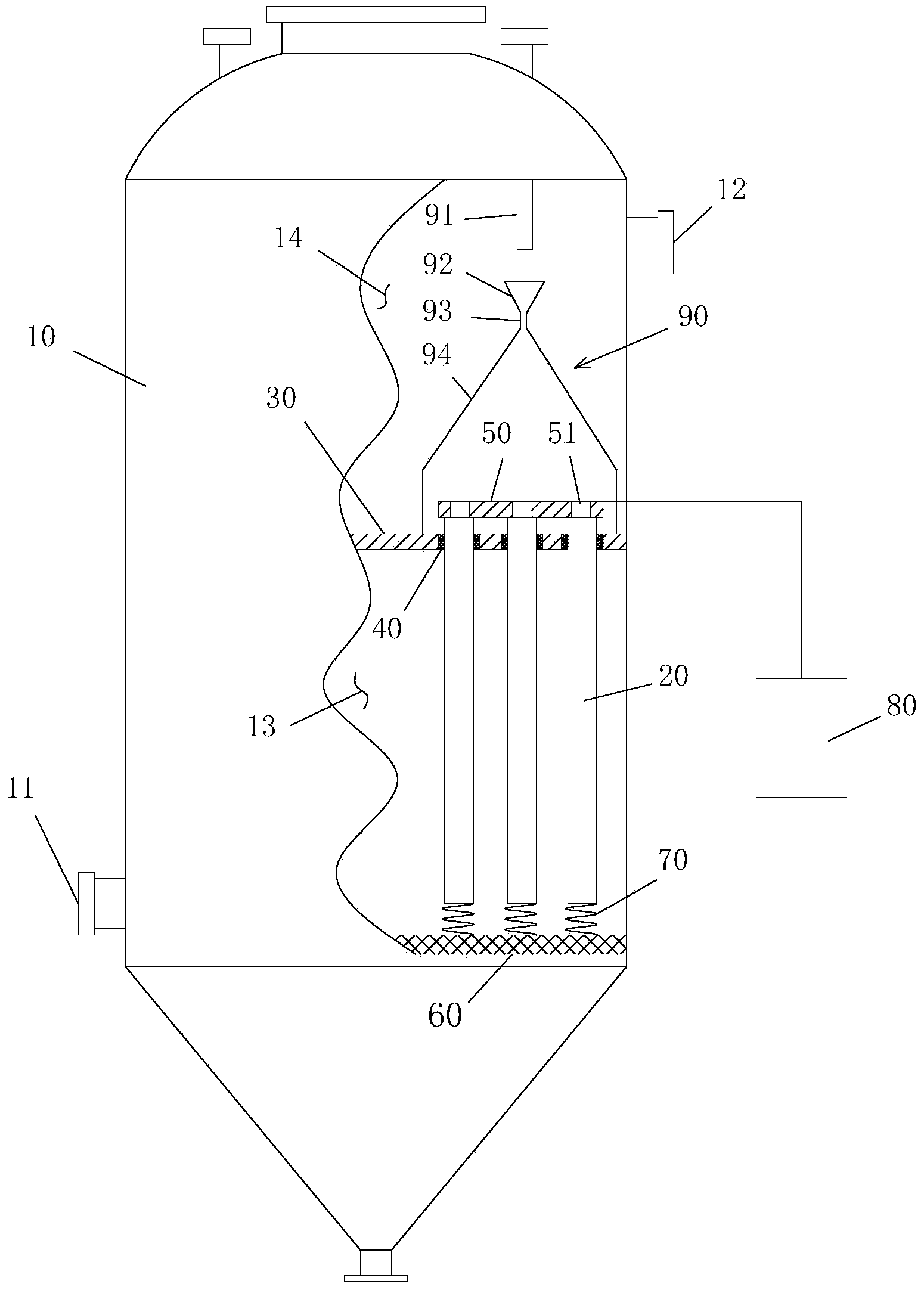

Gas filtration device

A filter device and gas technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low filter accuracy, dew condensation on the surface of the filter element, blockage of fine particles of the filter element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Adopt said gas filtering device in the above-mentioned specific embodiment, wherein used filter element 20 is the filter element that a kind of Fe-Al base alloy porous material is made, and the alloy composition of this material is: Fe accounts for 67% (weight); Al 20% by weight; Si 5% by weight; Ni 5% by weight and Mo 3% by weight. The material is prepared by powder metallurgy. The preparation method mainly includes three steps: material preparation, molding and sintering. The specific process is basically the same as the current process for preparing sintered porous materials by powder metallurgy. After heat preservation at 1300° C. for 2 hours, cooling is carried out to finally obtain the filter element 20 product. The resistance of the filter element is about 45Ω. Use the above-mentioned filter element 20 gas filter device to process the lead anode slime smelting furnace gas at a temperature of 400-500°C (Note: lead anode slime is a by-product produced in the proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com