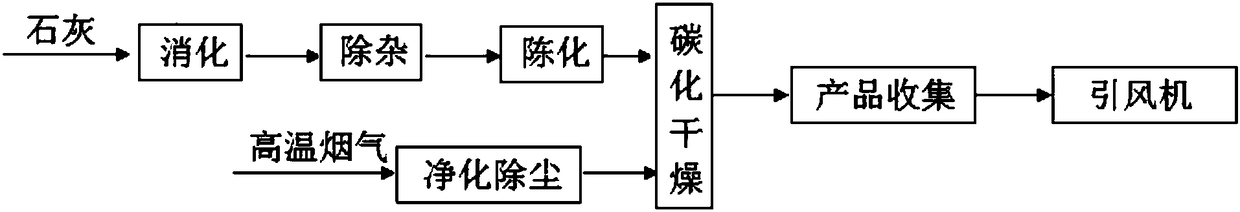

Production process and device for synthesizing calcium carbonate by carbonization and drying of high-temperature hot flue gas

A production process, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, energy input, etc., can solve the problems of clogging and wear of atomizing nozzles, bulky, complex slurry preparation system, etc., and achieves low operating costs and thermal expansion. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

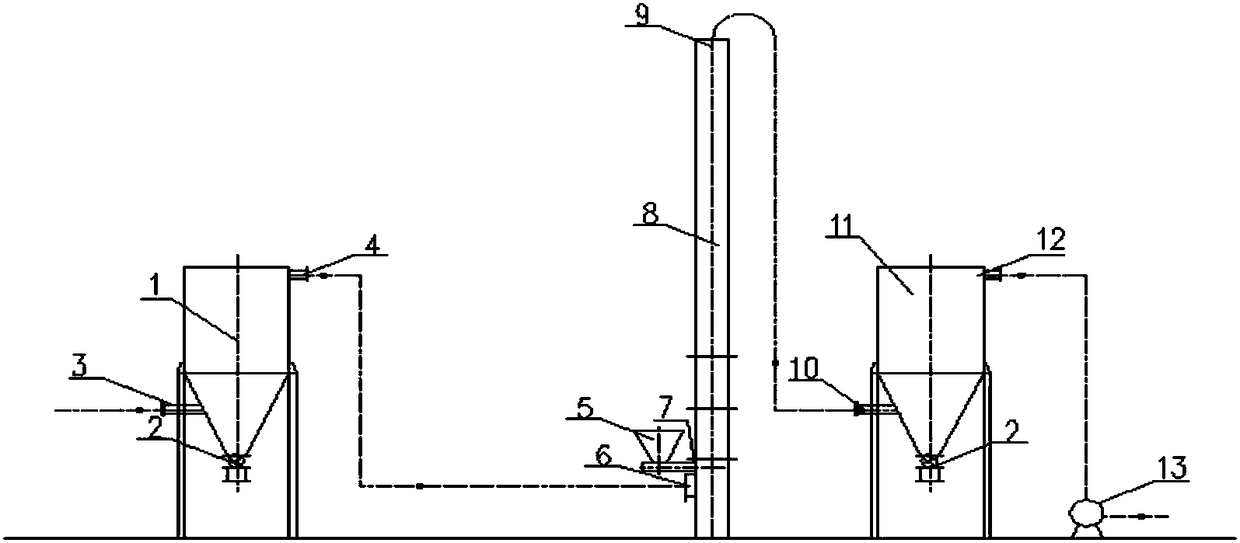

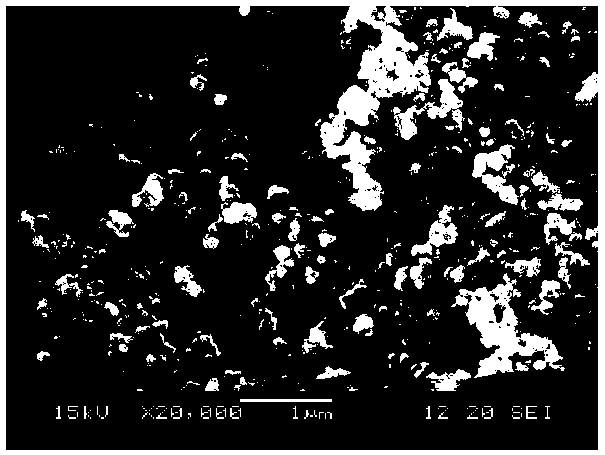

Embodiment 1

[0048] Keep the outlet temperature at 250°C and the dust concentration at 60g / Nm 3 , the flow rate is 11000m 3 The high-temperature hot flue gas at the kiln tail of the cement plant enters the flue gas purification dust collector through the induced draft fan, and after the dust is removed by the flue gas purification dust collector, the dust concentration of the hot flue gas at the outlet is ≤5mg / Nm 3 , CO 2 The content is 20% (volume fraction), and the hot flue gas after purification enters the reaction tower. The mass ratio of quicklime to water is 1:5, and the quicklime is added to 80°C water for digestion to obtain a calcium hydroxide solution; the calcium hydroxide solution is aged after removing impurities, and the aging time is 10h; calcium hydroxide removes part of the water Finally, the calcium hydroxide wet material is obtained, and the solid content is 50%. Calcium hydroxide wet material 510kg / h is added into the reaction tower by a screw feeder, the reaction te...

Embodiment 2

[0051] Set the outlet temperature at 450°C and the dust concentration at 100g / Nm 3 , the flow rate is 30000m 3 / h The hot flue gas of the high temperature fan at the kiln tail enters the flue gas purification dust collector through the induced draft fan. After the hot flue gas of the high temperature fan at the kiln tail is dusted by the flue gas purification dust collector, the dust concentration of the hot flue gas at the outlet is ≤10mg / Nm 3 , CO 2 Content 20% (volume fraction). The purified hot flue gas enters the reaction tower. The mass ratio of quicklime to water is 1:10, and the quicklime is added to water at 60°C for digestion to obtain a calcium hydroxide solution; the calcium hydroxide solution is aged after removing impurities, and the aging time is 5h; calcium hydroxide removes part of the water Finally, the calcium hydroxide wet material is obtained, and the solid content is 30%. Calcium hydroxide wet material 1500kg / h is fed into the reaction tower by a sc...

Embodiment 3

[0054] Keep the outlet temperature at 300°C and the dust concentration at 100g / Nm 3 , the flow rate is 20000m 3 / h The hot flue gas of the high temperature fan at the kiln tail enters the flue gas purification dust collector through the induced draft fan. After the hot flue gas of the high temperature fan at the kiln tail is dusted by the flue gas purification dust collector, the dust concentration of the hot flue gas at the outlet is ≤10mg / Nm 3 , CO 2 Content 20% (volume fraction). The purified hot flue gas enters the reaction tower. Industrial calcium carbide slag wet material 1100kg / h is fed into the reaction tower by a screw feeder, the reaction temperature is 200°C, the calcium carbide slag wet material with a solid content of 60% and CO 2 The gas undergoes carbonization and drying reactions, and dry calcium carbonate powder products can be obtained in the reaction tower. The dried calcium carbonate powder product enters the product collection dust collector with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com