Internal combustion engine with thermoelectric generator

A technology for internal combustion engines and thermoelectric generators, applied in the direction of generators/motors, internal combustion piston engines, combustion engines, etc., can solve the problems of small power output, and achieve the effects of saving space, reducing friction, and fast and powerful heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

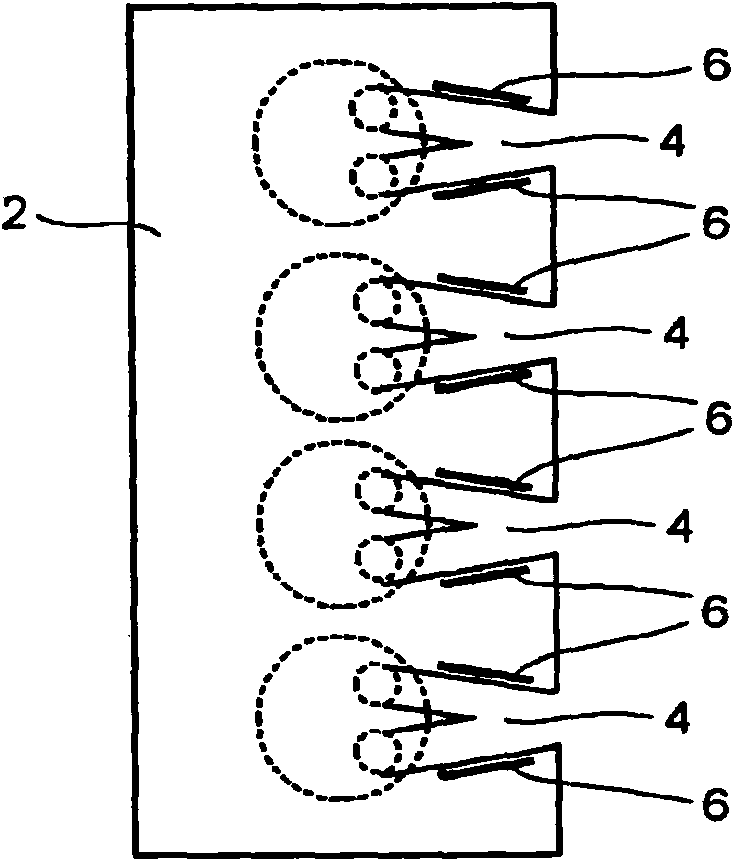

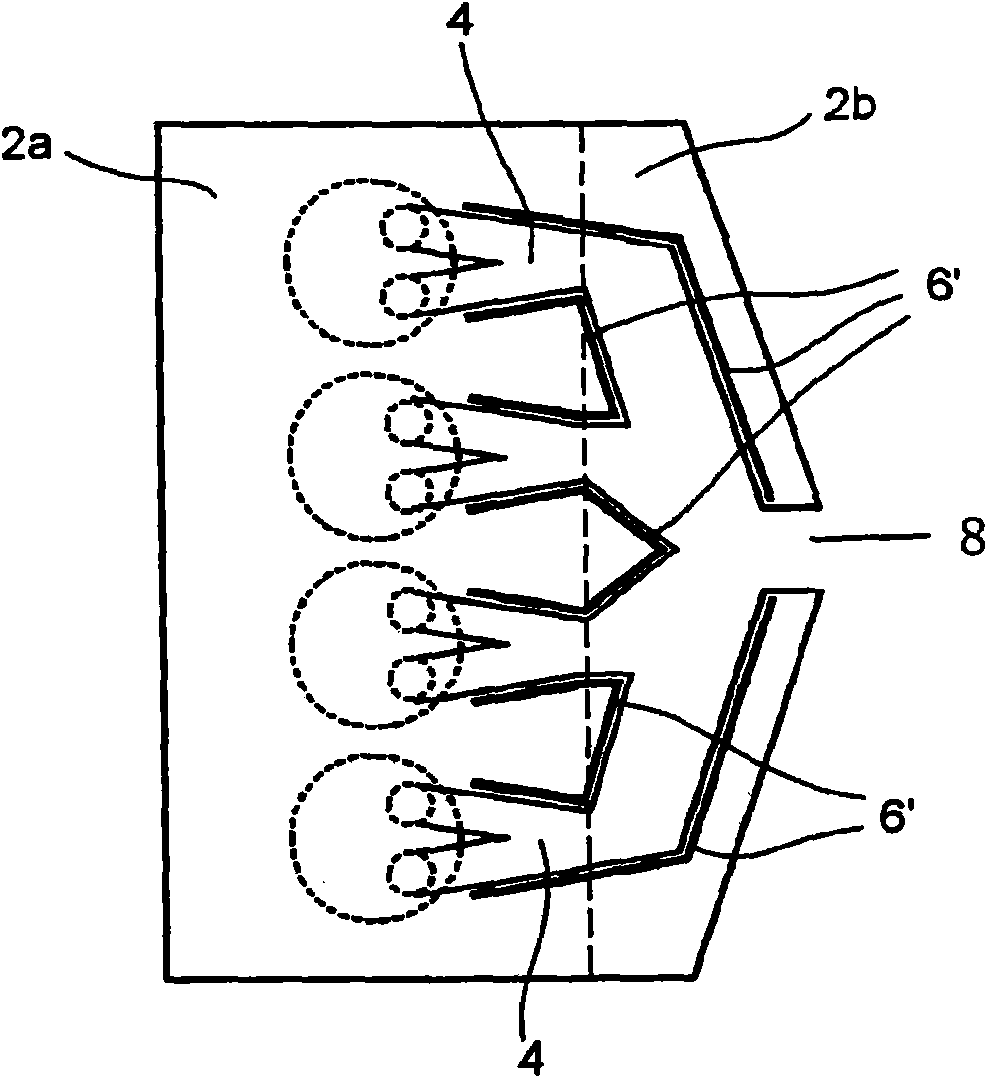

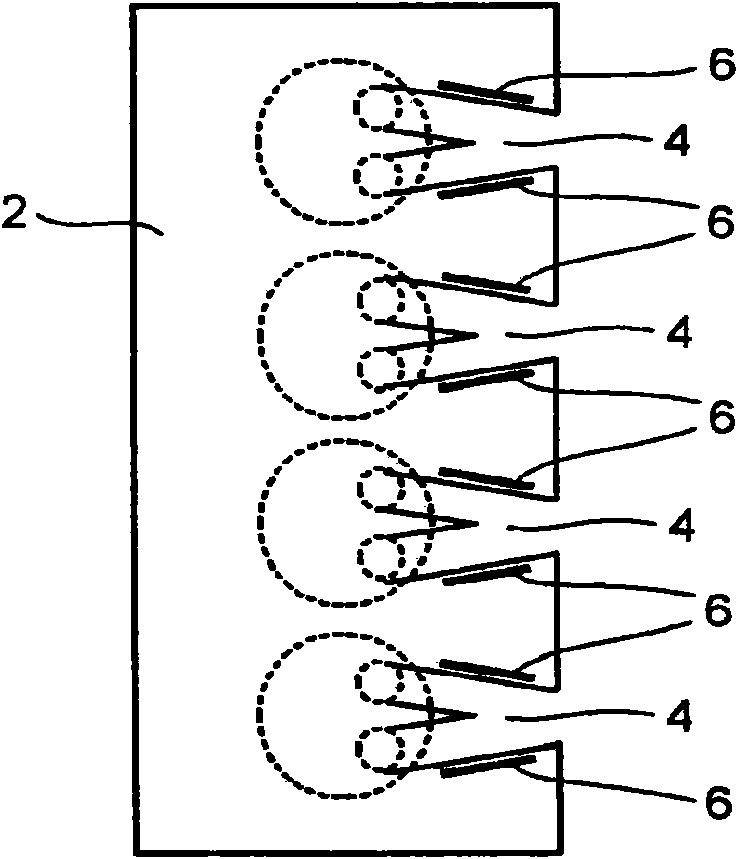

[0017] exist figure 1 In the cylinder head 2 shown, four cylinders and two exhaust valve openings in each cylinder are shown. At the start of the exhaust valve openings of each cylinder are exhaust ducts 4 converging in a V-shape, each V opening separately at the edge of the cylinder head 2 to a common row screwed to the cylinder head 2 gas collector (not shown).

[0018] A thermoelectric element 6 is arranged on the periphery of the exhaust duct 4 and is depicted with a thicker line, the thermoelectric element 6 being in thermal contact with the exhaust gas flowing through the exhaust duct 4 on the heat supply side and in thermal contact with the exhaust gas flowing through the cylinder head on the heat dissipation side. The coolant channels (not shown) in 2 are in thermal contact with the liquid coolant. In either case, there may be direct thermal contact or indirect thermal contact, for example via the metal of the cylinder head 2 , between the thermoelectric element 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com