Methods for preparing transition metal monoxide powder, target material and film

A transition metal and monoxide technology, applied in the field of synthesis and preparation, can solve the problems of restricting large-scale production and application, increasing unsafe factors, etc., achieve simple target preparation methods, shorten reaction time, and reduce high temperature resistance requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take by weighing 3.7474 grams of metal titanium powder, 6.2526 grams of titanium dioxide, take by weighing 5 grams of potassium chloride (0.5 times the mass) as a flux, after fully grinding, transfer to the quartz tube, then in less than 10 -3 Under the condition of Torr's vacuum, the quartz tube was encapsulated with an oxyhydrogen flame. Then place it in a muffle furnace at 900°C for 5 hours and take it out for quenching. Potassium chloride is washed away with distilled water, and TiO pure phase powder can be obtained after vacuum drying. Weigh 20 grams of the prepared TiO powder, place it in a graphite mold with a Φ of 1 inch, and compact it. Subsequently, the plasma discharge sintering method is used to sinter at 800 degrees Celsius and an argon atmosphere for 5 minutes to obtain a TiO dense target with a Φ of 1 inch.

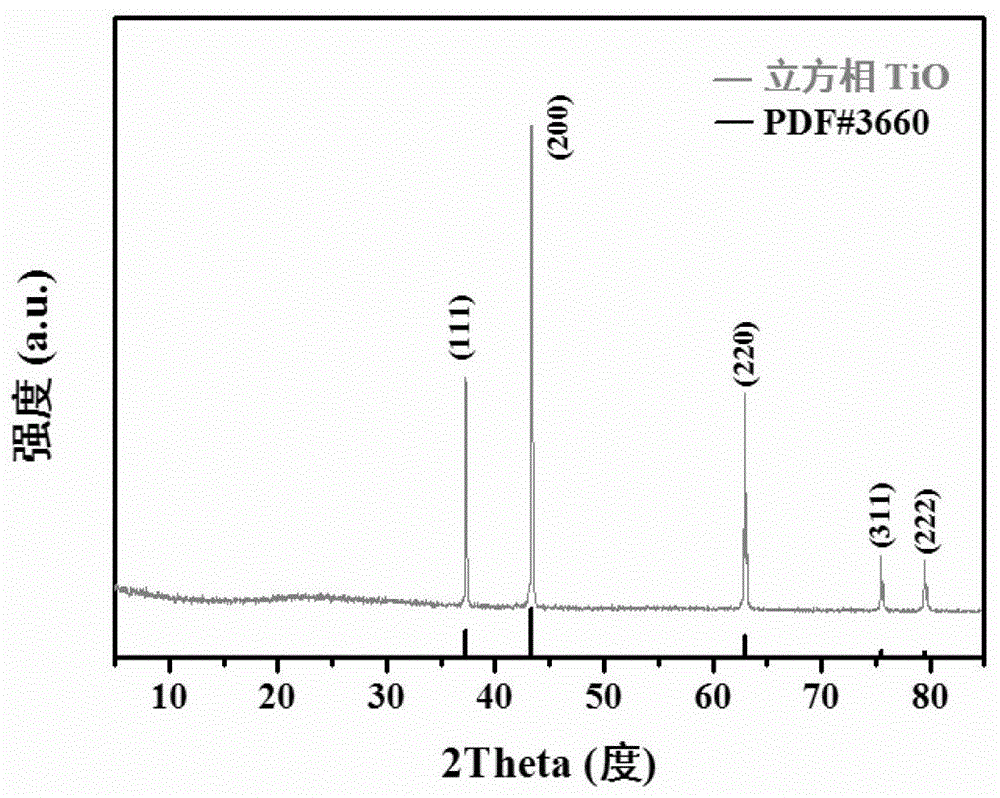

[0044] figure 1 It is the XRD figure of the obtained TiO sample of the embodiment of the present invention 1; As attached figure 1 As shown, the...

Embodiment 2

[0046] Take by weighing 3.7474 grams of metal titanium powder, 6.2526 grams of titanium dioxide, take by weighing 20 grams of potassium chloride (2 times the quality) as a flux, after fully grinding, transfer to the quartz tube, then in less than 10 -3 Under the condition of Torr's vacuum, the quartz tube was encapsulated with an oxyhydrogen flame. Then place it in a muffle furnace at 900°C for 5 hours and take it out for quenching. Potassium chloride is washed away with distilled water, and TiO pure phase powder can be obtained after vacuum drying.

[0047] Figure 6 It is the XRD pattern of the TiO sample obtained in Example 2 of the present invention. The XRD spectrum peak is consistent with the TiO standard peak, and no other miscellaneous peaks appear, indicating that potassium chloride twice the mass of the reactant is used as a sintering aid. Under these conditions, pure TiO samples can be obtained.

Embodiment 3

[0049] Take by weighing 4.4969 grams of metal titanium powder, 7.5031 grams of titanium dioxide, take by weighing 6 grams of potassium chloride (2 times the quality) as a flux, after fully grinding, transfer to a quartz tube, then in less than 10 -3 Under the condition of Torr's vacuum, the quartz tube was encapsulated with an oxyhydrogen flame. Then place it in a muffle furnace at 1100 degrees Celsius to react for 5 hours, take it out and quench it directly. Potassium chloride is washed away with distilled water, and TiO pure phase powder can be obtained after vacuum drying.

[0050] Figure 7 It is the XRD pattern of the TiO sample obtained in Example 3 of the present invention. The XRD spectrum peak is consistent with the TiO standard peak, and no other miscellaneous peaks appear, indicating that potassium chloride twice the mass of the reactant is used as a sintering aid. Under these conditions, pure TiO samples can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com