Ramjet engine

A jet engine, high-pressure air cavity technology, applied in ramjet engines, mechanical equipment, etc., can solve the problems of insufficient heat utilization, fuel waste, environmental pollution, etc., to reduce temperature, shape unlimited, reduce The effect of environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

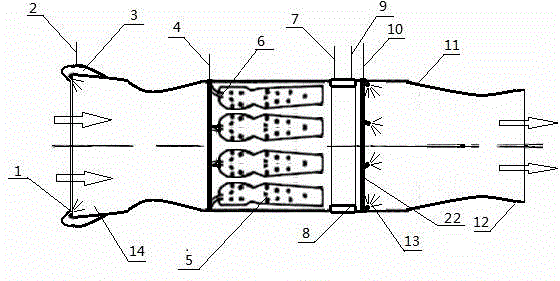

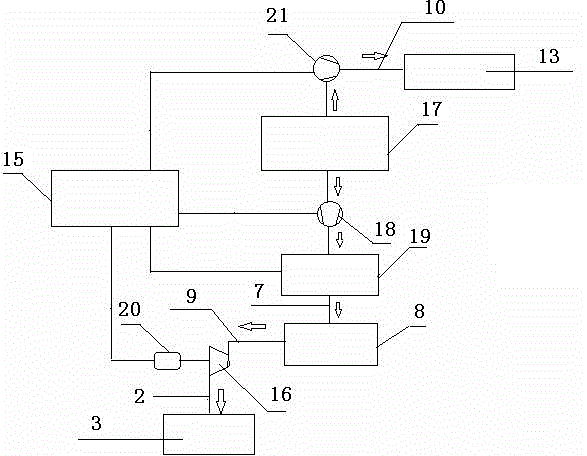

[0032] Combine below figure 1 and figure 2 , the present invention is further described:

[0033] Such as figure 1 Shown, a kind of ramjet engine comprises intake duct 14, combustion chamber 5 and exhaust pipe, and air diversion structure is arranged at the inlet end of intake duct 14, and air diversion structure comprises high-pressure air input pipe 2, high-pressure air cavity 3 and The nozzle 1 and the high-pressure air chamber 3 are connected to the air inlet 14, and the high-pressure air in the high-pressure air input pipe 2 enters the high-pressure air chamber 3 and enters the air inlet 14 through the nozzle to realize the Coanda effect of hydrodynamics. The high-pressure air chamber 3 is an annular high-pressure air chamber, which is fixedly attached to the outer wall of the air inlet 14, and the nozzles are multiple and annularly distributed on the inner wall of the air inlet 14. The annular high-pressure air cavity can achieve better Coanda effect; the nozzle can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com