Preparation method of modified nickel hydroxide positive electrode material

A positive electrode material, nickel hydroxide technology, applied in the field of preparation of modified nickel hydroxide positive electrode material, can solve the problem of poor electronic conductivity of positive electrode, achieve the effect of improving conductivity, reducing cost and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of modified nickel hydroxide positive electrode material, the steps are as follows:

[0041] (1) Preparation of cathode material:

[0042] In the electrolytic cell equipped with a diaphragm, nickel sulfate, zinc sulfate, manganese sulfate and aluminum sulfate solutions with a concentration of 0.5M / L are added to the cathode chamber, and the molar ratio of each salt is 9:0.5:0.3:0.2. The anode chamber is filled with 0.5M / L potassium sulfate solution, with nickel foam as the cathode and platinum as the anode. 0.1M / L ammonium chloride and 0.5M / L ammonia water are complexing agents, and sodium hydroxide solution is used to adjust the pH to 8 at 3mA / cm 2 Constant current electrolysis for 10 h, electrolysis at 50° C., to obtain the positive electrode material deposited on the nickel foam.

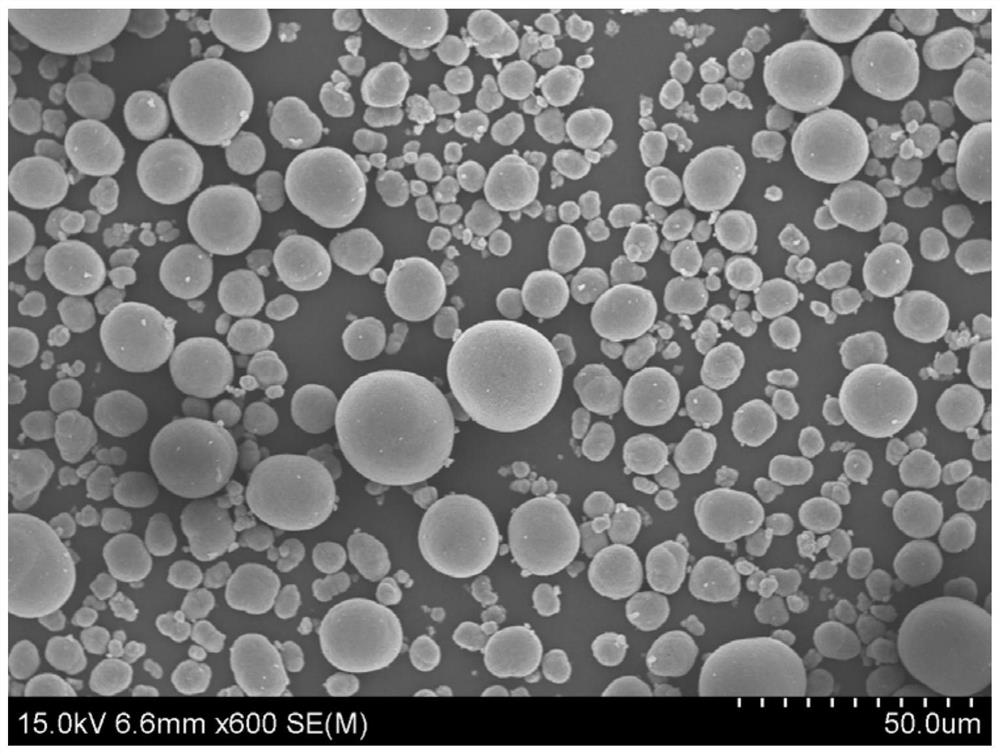

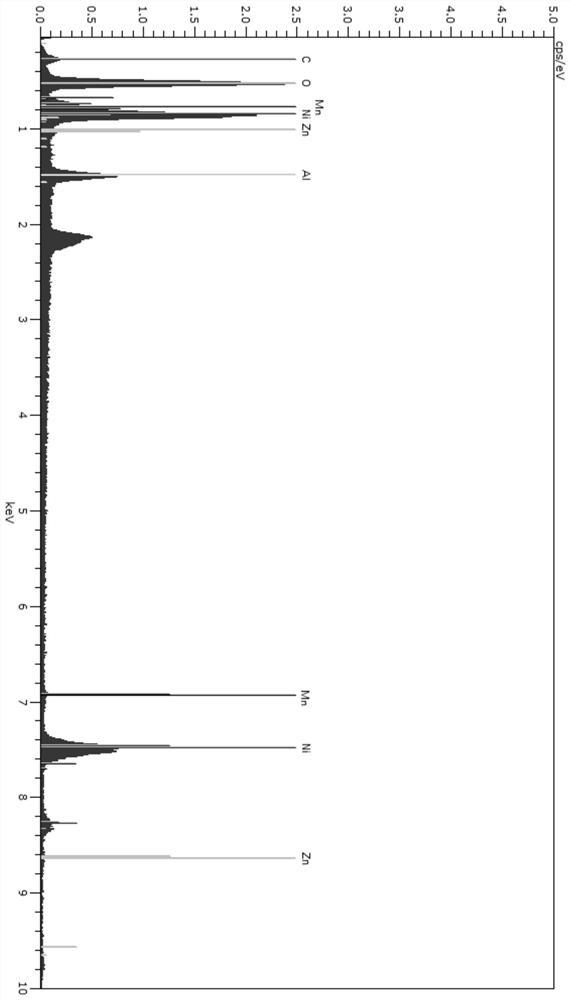

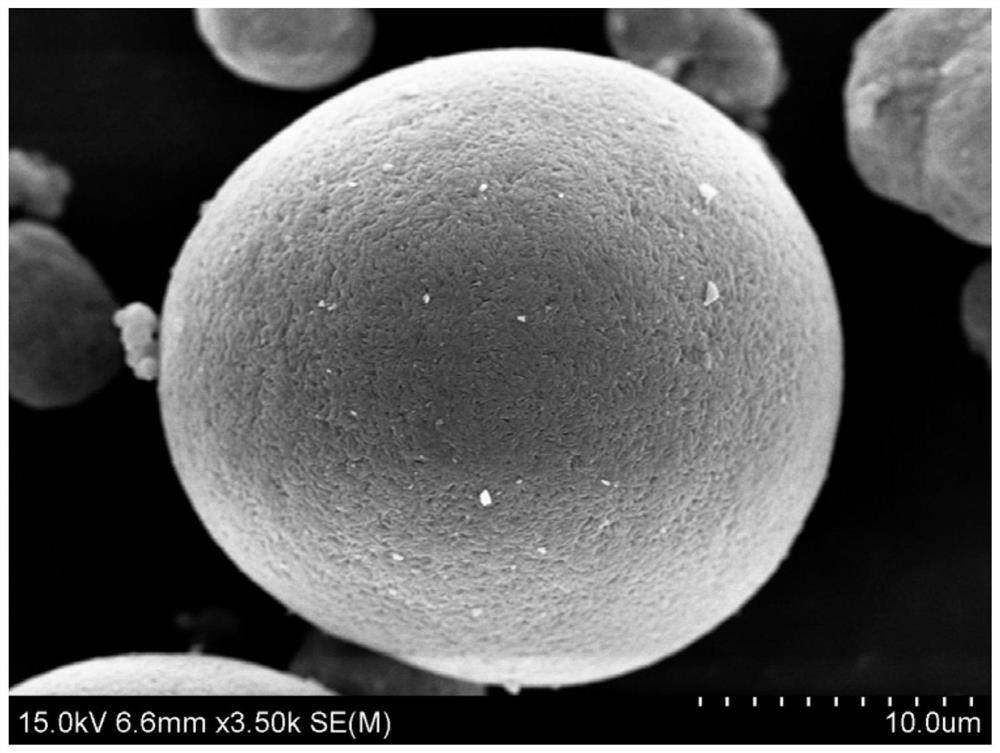

[0043] The multi-component positive electrode has been tested by scanning electron microscope and energy spectrum, such as figure 1 and figure 2 shown.

[0044] ...

Embodiment 2

[0047] A preparation method of modified nickel hydroxide positive electrode material, the steps are as follows:

[0048] (1) Preparation of cathode material:

[0049] Nickel sulfate, zinc sulfate, manganese sulfate and aluminum sulfate are configured into a mixed solution A with a concentration of 0.5M / L, and the molar ratio of each salt is 9:0.5:0.3:0.2. Prepare sodium hydroxide solution B with a concentration of 0.5M / L and ammonia solution C with a concentration of 0.1M / L; under the condition of mechanical stirring at 400r / min, the reaction temperature is controlled at 50°C, and three kinds of A, B, and C are added dropwise at the same time Control the pH of the solution to 10, react continuously for 8 hours, wash with deionized water, and dry to obtain the positive electrode material Ni 0.9 Zn 0.05 mn 0.03 al 0.02 (OH)2 .

[0050] (2) Conductive material coating:

[0051] The aniline hydrochloride and the positive electrode material were mixed in water at a mass ratio...

Embodiment 3

[0053] A preparation method of modified nickel hydroxide positive electrode material, the steps are as follows:

[0054] (1) Preparation of cathode material:

[0055] In the electrolytic cell equipped with a diaphragm, the cathode chamber is filled with nickel chloride, zinc chloride, manganese chloride and magnesium chloride solutions at a concentration of 2M / L, and the molar ratio of each salt is 9:0.5:0.3:0.2. The anode chamber is filled with 2M / L potassium nitrate solution, nickel foam is used as the cathode, and platinum is used as the anode. 1M / L ammonium chloride and 1M / L ammonia water are complexing agents, and sodium hydroxide solution is used to adjust the pH to 10 at 1mA / cm 2 Constant current electrolysis for 5 hours, electrolysis at 50° C., to obtain the positive electrode material deposited on the nickel foam.

[0056] (2) Conductive material coating:

[0057] In the electrolytic cell, graphite and nickel foam deposited with positive electrode materials are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com