Oil-water well sand consolidation agent as well as preparation method and application thereof

A sand-fixing agent and technology for oil-water wells, applied in chemical instruments and methods, and drilling compositions, etc., can solve problems such as low rock cementation strength, inability to fix sand, and sand particles entering oil wells, so as to facilitate oil exploitation and facilitate Large-scale promotion and application, the effect of enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

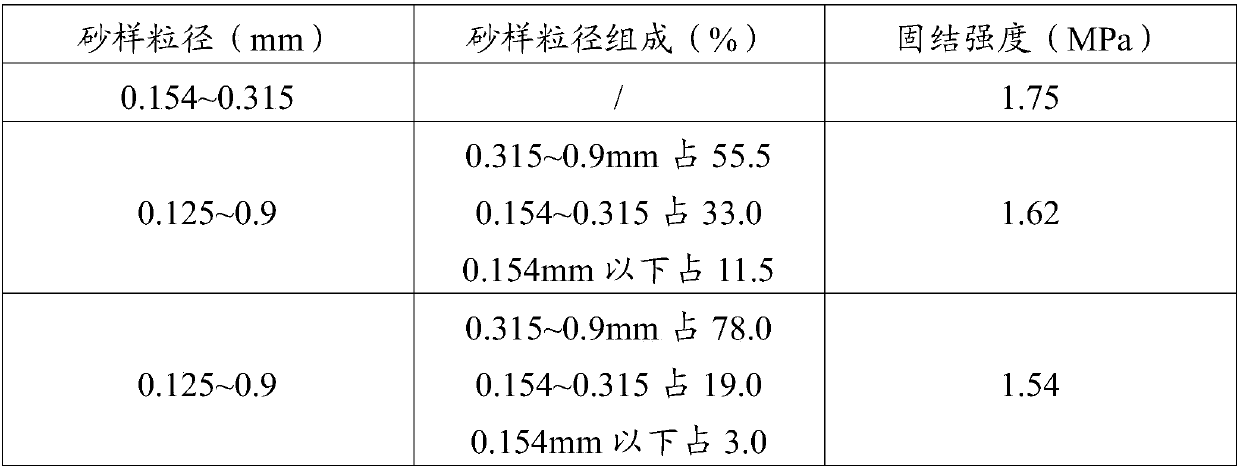

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the second aspect, the embodiment of the present invention also provides the preparation method of the above-mentioned oil-water well sand-consolidating agent, comprising the following steps: according to the weight percentage of each component in the oil-water well sand-consolidating agent, adding water, coupling agent and Carboxamide or ammonium carbonate, stir at 25°C-35°C for 25-35min, add silicate, continue stirring for 55-65min, until the solution in the reaction kettle is milky white, the oil-water well sand cementing agent is obtained.

[0032] Specifically, in order to fully hydrolyze and mix the components in the oil-water well sand cementing agent, the stirring speed during the preparation process is 30-50r / min, such as 30r / min, 35r / min, 40r / min, 45r / min , 50r / min, etc., so that the oil-water well sand-fixing agent can fully exert its sand-fixing effect after entering the oil well, and control or reduce the sand production of the oil reservoir.

[0033] Sp...

Embodiment 1

[0039] This embodiment provides a kind of oil-water well sand-consolidating agent, and this oil-water well sand-consolidating agent comprises the following components by weight percentage: aqueous solution of sodium silicate 42%, carbonamide 17.5%, coupling agent LY0.09%, The balance is water.

[0040] Wherein, and the mass fraction of sodium silicate in the aqueous solution of sodium silicate is 36%, in the aqueous solution of sodium silicate, SiO 2 with Na 2 The molar ratio of O was 3.1.

[0041] The oil-water well sand cementing agent is prepared by the following method:

[0042] According to the above dosage, add water, coupling agent LY and carbonamide to the reaction kettle, stir at 25°C for 30 minutes, add the aqueous solution of sodium silicate and ammonium bicarbonate, and continue to stir for 60 minutes until the solution in the reaction kettle is When it is milky white, the oil-water well sand cementing agent is obtained.

Embodiment 2

[0053] This embodiment provides a kind of oil-water well sand-consolidating agent, and this oil-water well sand-consolidating agent comprises the following components by weight percentage: aqueous solution of sodium silicate 42.5%, ammonium carbonate 12.5%, ammonium bicarbonate 0.55%, coupling agent LY0 .08%, balance water.

[0054] Wherein, and the mass fraction of sodium silicate in the aqueous solution of sodium silicate is 36%, SiO in sodium silicate 2 with Na 2 The molar ratio of O is 3.2.

[0055] The oil-water well sand cementing agent is prepared by the following method:

[0056] According to the above dosage, add water, coupling agent LY and ammonium carbonate to the reaction kettle, stir at 30°C for 25 minutes, add the aqueous solution of sodium silicate and ammonium bicarbonate, and continue stirring for 55 minutes until the solution in the reaction kettle is milky white , to obtain sand cementing agent for oil and water wells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com