Reservoir perforating method and device

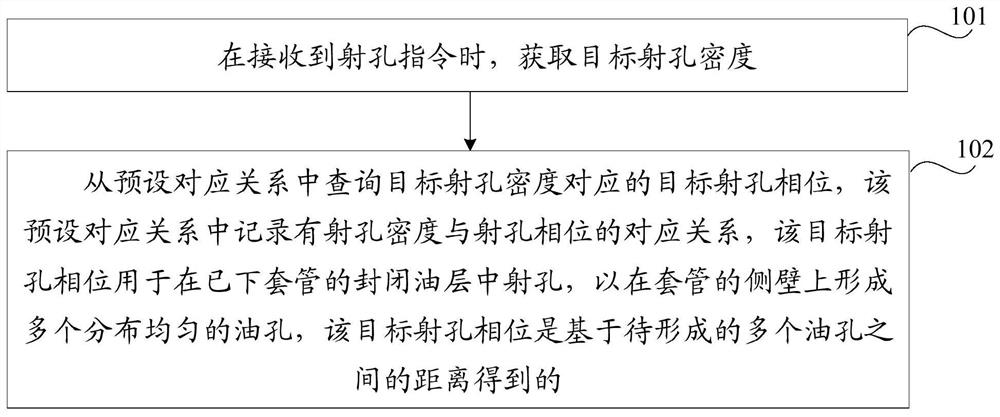

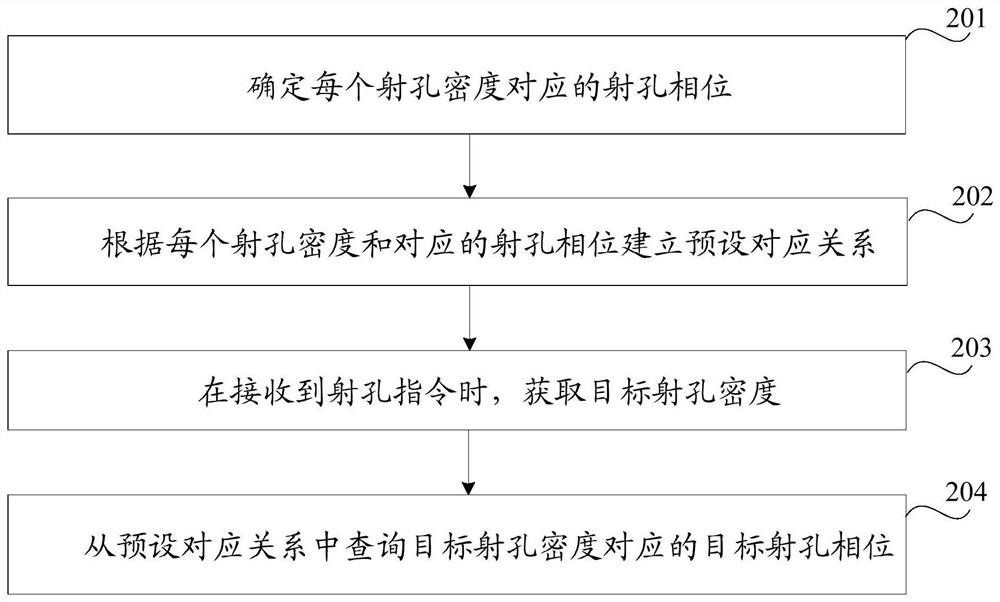

A perforation and oil hole technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of large productivity loss and severe sand production in oil and gas wells, and achieve the goal of reducing the degree of sand production, increasing productivity, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

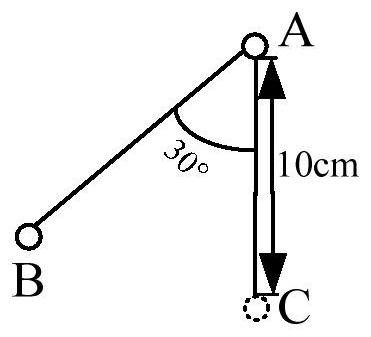

[0063] In related technologies, after the perforation density is determined, the staff will determine the perforation phase based on experience based on the perforation density, and then use the perforating gun to shoot oil holes according to the determined perforation phase, thereby establishing the connection between the wellbore and the formation. Allows fluid to enter the wellbore. Among them, the perforation density refers to the number of oil holes per meter, and the perforation phase refers to the deflection angle of the line connecting the center points of two adjacent oil holes relative to the vertical direction. In order to enable readers to understand the perforation phase more accurately, the perforation phase is now explai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com