Methods of mining gas hydrates

A technology for natural gas and hydrate, applied in the fields of fluid extraction, coal gasification, and earth-moving drilling, etc., can solve the problems of polluted environment, serious sand production, low productivity, etc., achieve high reservoir sweep rate, prevent formation collapse, reduce The effect of differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

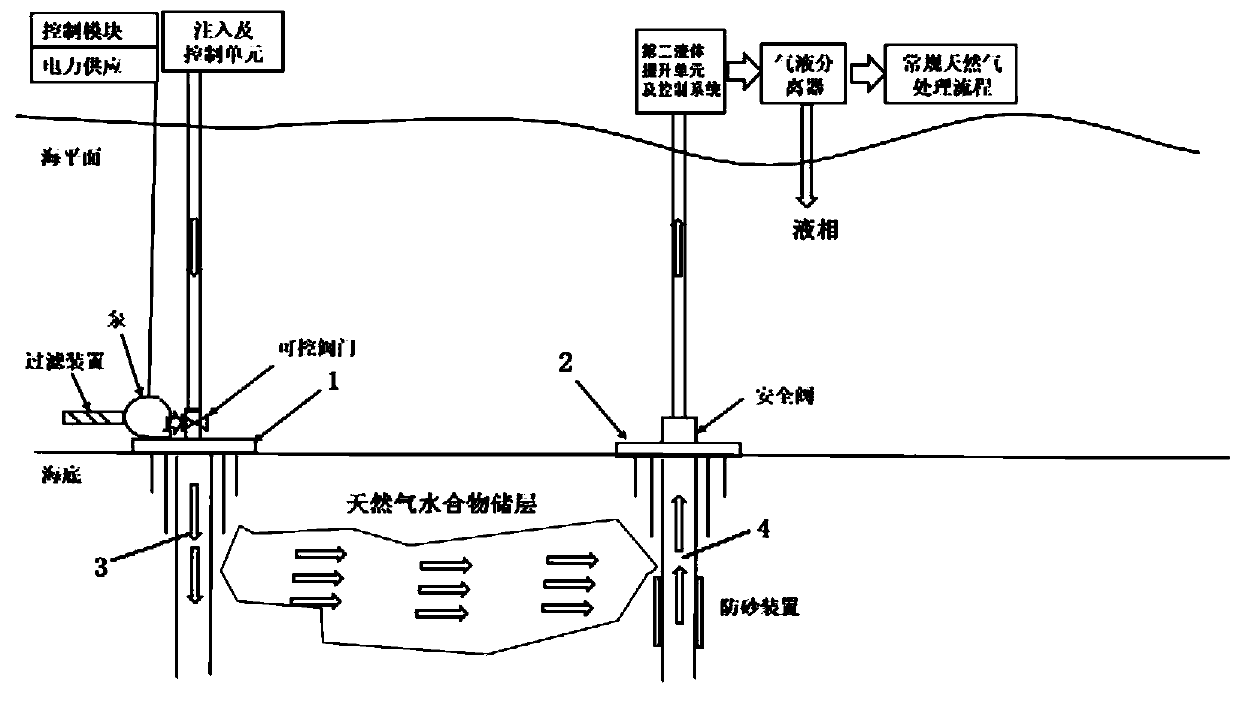

[0077] Such as figure 1 As shown, the system has an injection well 1 and a production well 2. The production well and the production well are completed by fracturing, and the production well 2 is equipped with a complete set of sand control system, and the mud line is equipped with a safety valve. The production pipeline connects the wellhead safety valve and the platform. The platform is equipped with the second fluid lifting unit and control system, gas-liquid separation system, gas pretreatment system and gas transmission system. The water injection well has a power supply system, a control system, an injection and control unit, a filtration system and an electric submersible pump.

[0078] In the mining process, the first fluid (mineral oil containing Span, containing 4-12 carbon atoms, dynamic viscosity of 1-20mPa·s, and Span content of 2g / 100mL) is pumped into the reservoir by an underwater electric pump, the first fluid (temperature is 2°C, pressure is 8MPa) migrate...

Embodiment 2

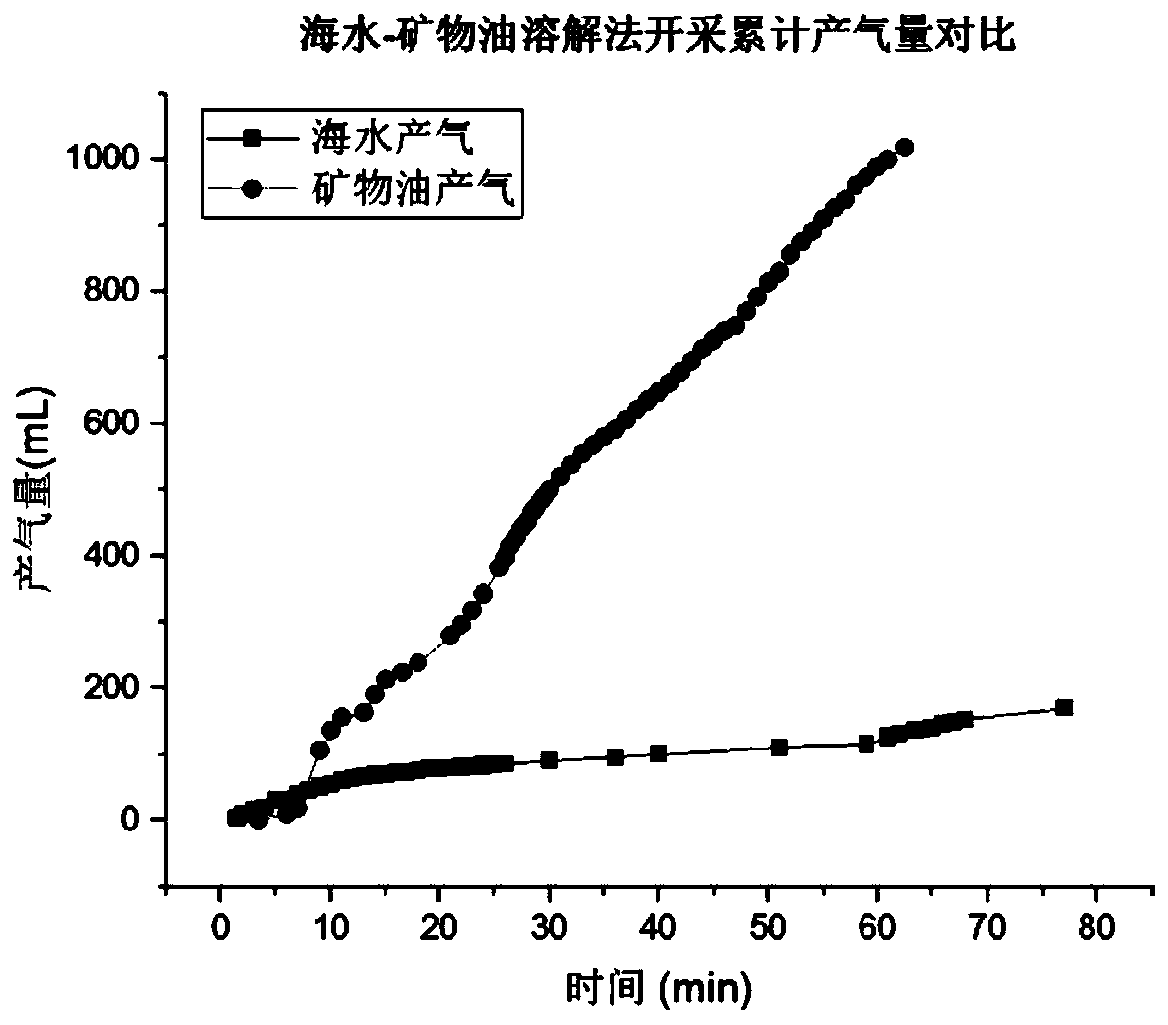

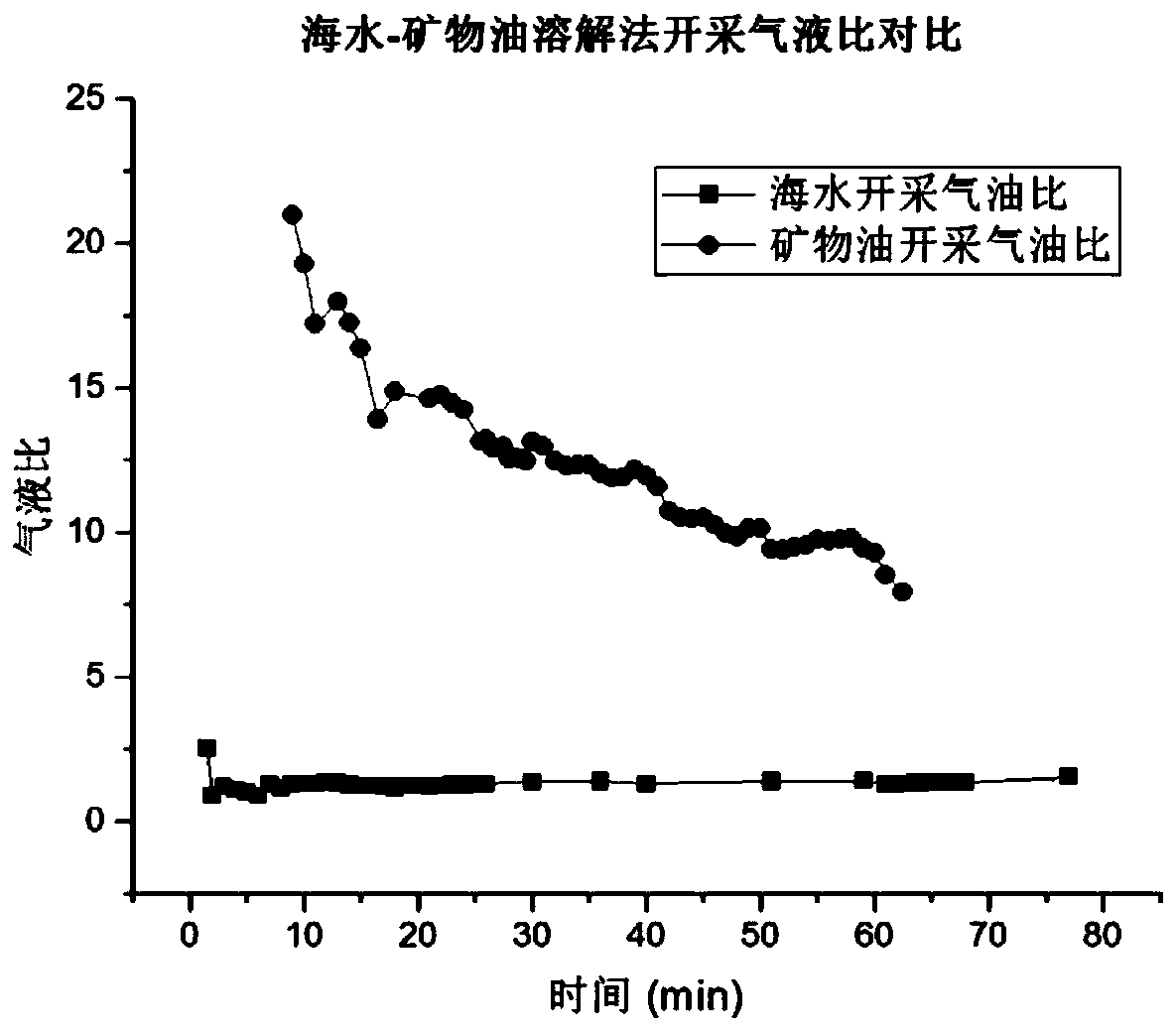

[0083] Referring to the method described in Example 1 to exploit natural gas hydrate, the difference is that only the mineral oil described in Example 1 is used as the first fluid. All the other are identical with embodiment 1. The mining results are shown in Table 1.

Embodiment 3

[0085] Referring to the method described in Example 1 to exploit natural gas hydrate, the difference is that the mixed solution of mineral oil and water described in Example 1 is used (the volume ratio of mineral oil to water is 8:2, and the content of Sipan is 4g / 100mL ) as the first fluid. All the other are identical with embodiment 1. The mining results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com