Photoetching method capable of reducing width of exposure pattern

A technology for exposing graphics and width, which is applied in the direction of photosensitive materials, electrical components, semiconductor/solid-state device manufacturing for optomechanical equipment, etc., to achieve the effect of small width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the photolithography method for reducing the width of the exposure pattern provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

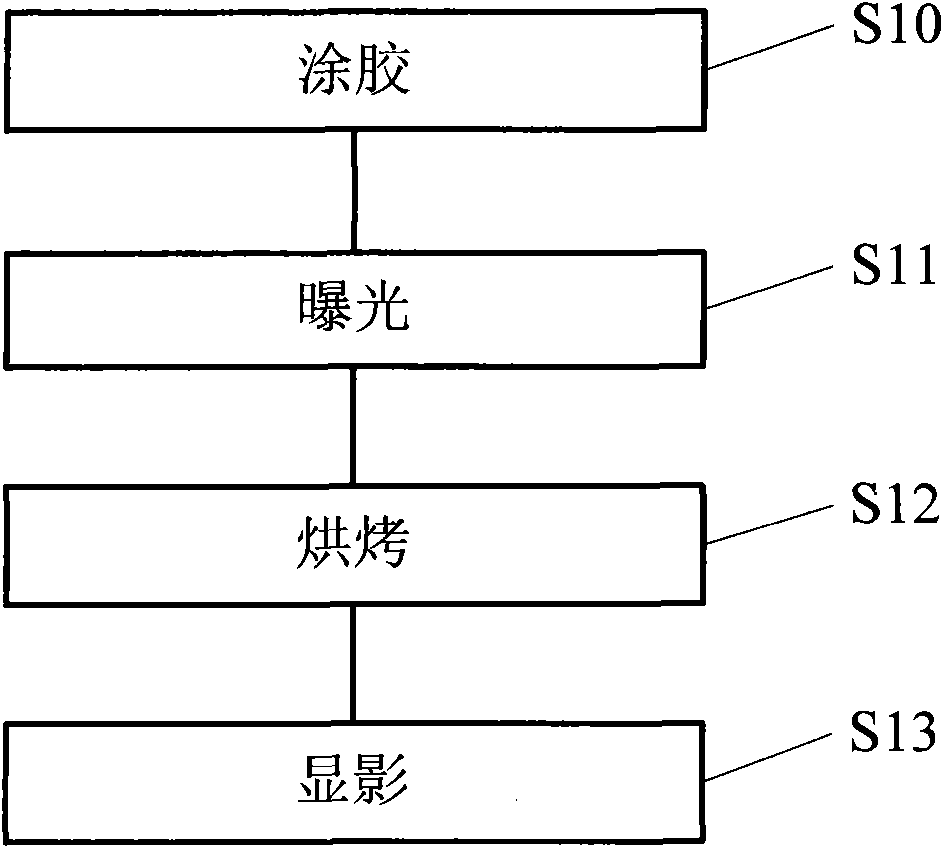

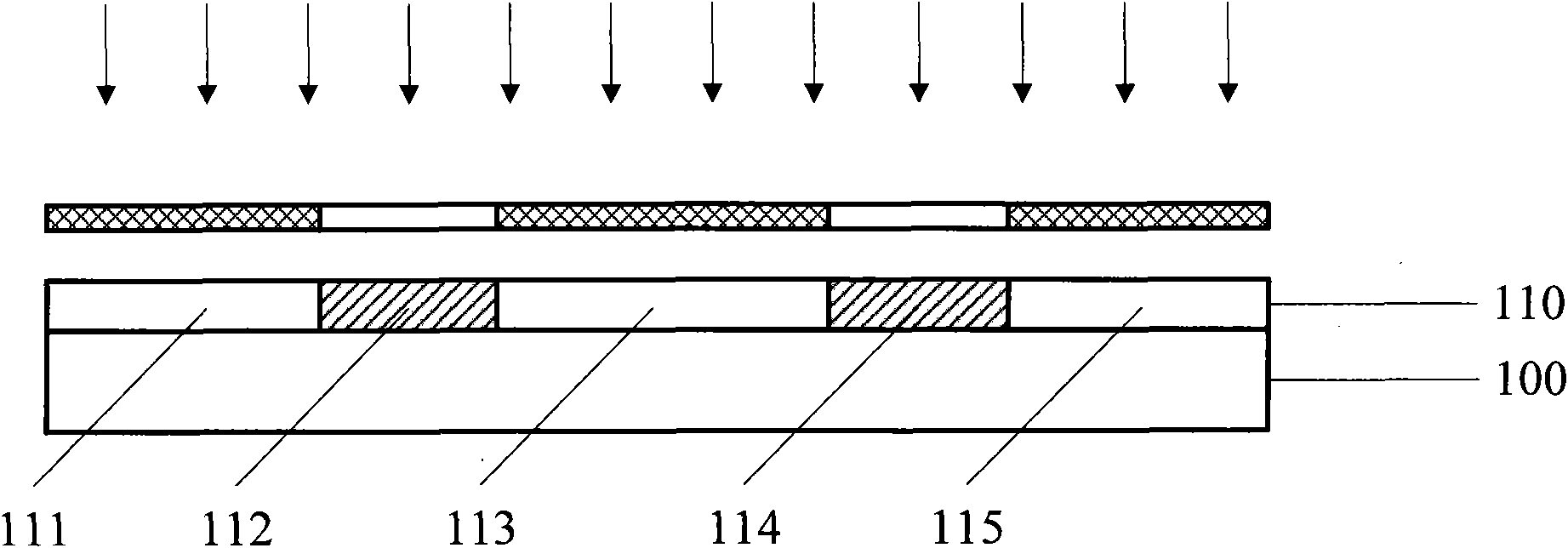

[0030] attached Figure 5 It is a process flow chart of a specific embodiment of the photolithography method for reducing the width of the exposure pattern in the present invention. Step S20, providing a semiconductor substrate with a photoresist layer on the surface; Step S21, exposing the photoresist layer to define patterns in the photoresist layer; Step S22, using a passivator containing trivalent nitrogen atoms and The photoresist layer after exposure undergoes a passivation reaction, and the trivalent nitrogen atoms in the passivation agent combine with hydrogen ions existing on the surface and sides of the exposed part of the photoresist layer to form The cladding layer; Step S23 , developing the passivated photoresist layer to remove the unex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com