Method for efficiently grinding and polishing GaN chips

A high-efficiency, wafer-based technology, applied in the direction of grinding equipment, grinding machine tools, electrical components, etc., can solve the problems of difficult to obtain high-quality polished surface, accelerate GaN surface oxidation corrosion, long polishing cycle and low efficiency, and achieve improved flatness and roughness, prevent mechanical scratches, improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

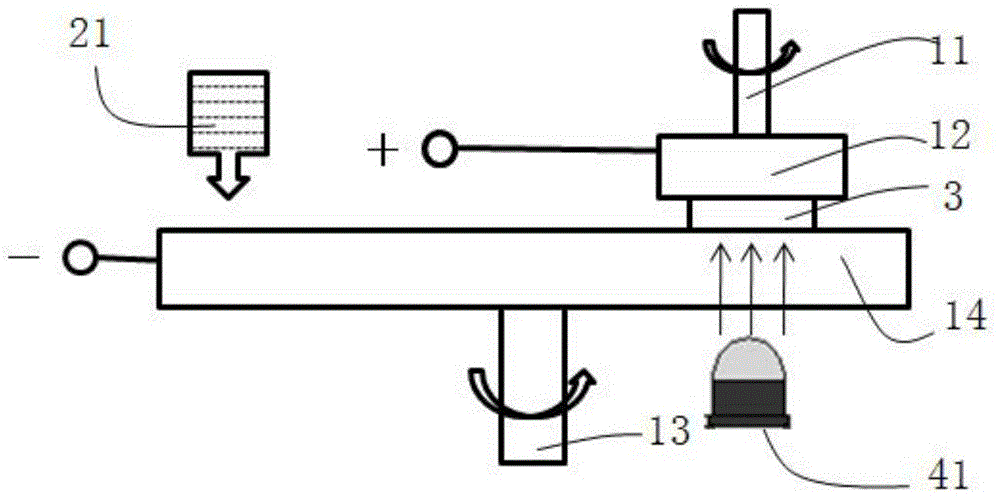

[0016] Such as figure 1 As shown, the upper tray 12 is connected to the positive pole of the power supply, and its rotation is realized through the upper rotating shaft 11 , and the lower polishing disc 14 is connected to the negative pole of the power supply, and its rotation is realized through the lower rotating shaft 13 . The cleaned and dried GaN wafer 3 is fixed on the upper tray 12 of the polishing device, so that the surface to be polished of the GaN wafer 3 faces the front of the lower polishing disc 14 and is in a contact or semi-contact state; the light source 41 is turned on to illuminate the GaN wafer 3 on the surface to be polished; set the appropriate voltage value and turn on the power to make the upper tray 12, the GaN wafer 3 to be polished, and the lower polishing disc 14 form a current loop; after a certain oxide layer is formed on the surface to be polished, the polishing liquid 21 is sprayed to open the polishing device. All rotation procedures, and apply...

Embodiment 2

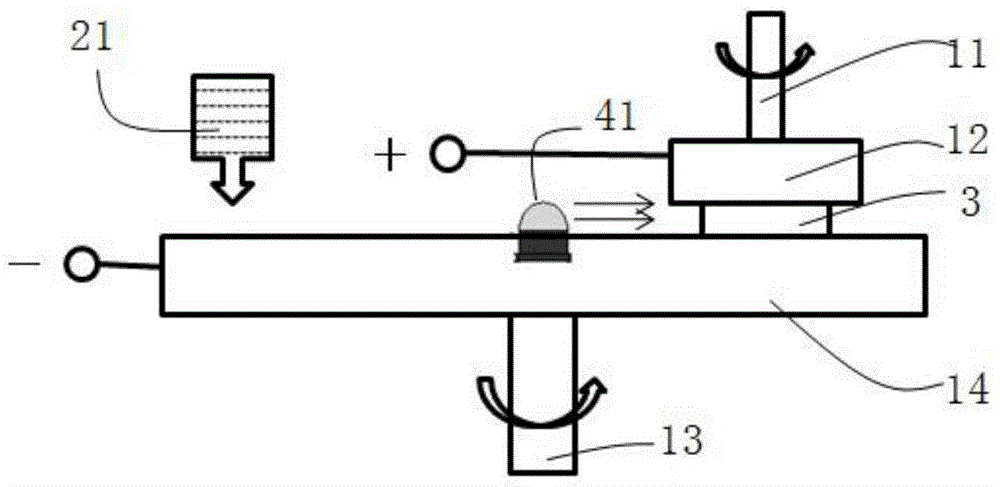

[0018] Such as figure 2 As shown, the upper tray 12 is connected to the positive pole of the power supply, and its rotation is realized through the upper rotating shaft 11 , and the lower polishing disc 14 is connected to the negative pole of the power supply, and its rotation is realized through the lower rotating shaft 13 . The cleaned and dried GaN wafer 3 is fixed on the upper tray 12 of the polishing device, so that the surface to be polished of the GaN wafer 3 faces the front of the lower polishing disc 14 and is in a semi-contact state; Side and the surface to be polished; set the appropriate voltage value and turn on the power to make the upper tray 12, the GaN wafer 3 to be polished, and the lower polishing disc 14 form a current loop; after a certain oxide layer is formed on the surface to be polished, spray the polishing liquid 21, and open the polishing device. All rotation procedures, and apply suitable downward pressure on the upper tray 12, remove the oxide lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com