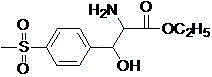

Preparation method of p-methyl sulfone phenyl ethyl serinate

A technology for methylsulfonyl phenylserine ethyl ester and methylsulfonyl phenylserine ethyl ester, which is applied in the field of preparation of p-methylsulfonyl phenylserine ethyl ester, can solve problems such as failure to meet requirements, cancellation of production qualifications, and the like, and achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Synthesis of p-Methylsulfonyl Phenylserine

[0016] Dissolve 20g of copper p-methylsulfonylphenylserine in sodium hydroxide solution (6g NaOH dissolved in 84mL water), add Na 2 S solution (12.1g Na 2 S was dissolved in 17 mL of water), stirred mechanically for 4 hours, then added 8 g of activated carbon to the mixture, stirred mechanically for 1 hour, and filtered with suction. The filtrate was transferred to a 250mL three-necked flask, concentrated hydrochloric acid was added dropwise to adjust the pH to 3, the crystals were concentrated, and filtered with suction to obtain 13.39g of p-methylsulfonylphenylserine with a yield of 75.4%.

Embodiment 2

[0018] Synthesis of p-Methylsulfonyl Phenylserine

[0019] Dissolve 20g of copper p-methylsulfonylphenylserine in sodium hydroxide solution (6g NaOH dissolved in 84mL water), add Na 2 S solution (12.1g Na 2 S was dissolved in 17 mL of water), stirred mechanically for 4 hours, then added 8 g of activated carbon to the mixture, stirred mechanically for 1 hour, and filtered with suction. The filtrate was transferred to a 250 mL three-necked flask, concentrated hydrochloric acid was added dropwise to adjust the pH to 4, the crystals were concentrated, and filtered with suction to obtain 13.5 g of p-methylsulfonyl phenylserine with a yield of 76%.

Embodiment 3

[0021] Synthesis of p-Methylsulfonyl Phenylserine

[0022] Dissolve 20g of copper p-methylsulfonylphenylserine in sodium hydroxide solution (6g NaOH dissolved in 84mL water), add Na 2 S solution (12.1g Na 2 S was dissolved in 17 mL of water), stirred mechanically for 4 hours, then added 8 g of activated carbon to the mixture, stirred mechanically for 1 hour, and filtered with suction. The filtrate was transferred to a 250 mL three-necked flask, concentrated hydrochloric acid was added dropwise to adjust the pH to 5, the crystals were concentrated, and filtered with suction to obtain 13.85 g of p-methylsulfonyl phenylserine with a yield of 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com