High-strength light plate material and manufacture method thereof

A high-strength, plate technology, applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., to achieve good thermal insulation performance, low manufacturing cost, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

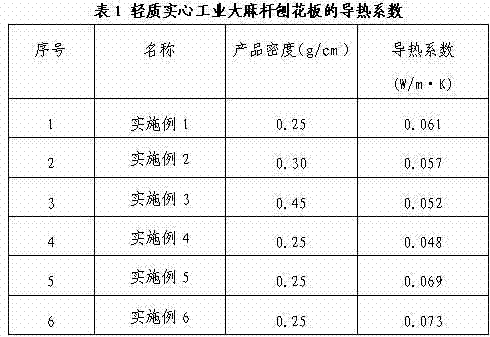

[0021] Example 1 Preparation of industrial hemp rod lightweight solid particleboard

[0022] Adjust the moisture content of industrial hemp stalks to 30-50%. After peeling off the skin of the hemp stalks, use a chipper to crush the obtained stalk cores into 5-10cm long pieces, and then use a double-drum planer to further break the pieces. into shavings, and use a screening machine to screen to obtain qualified shavings with a length of 5-10mm, a thickness of 3-5mm, and a width of 3-5mm. Use a rotor dryer to dry the shavings to a moisture content of 3-5% at a temperature of 140°C; then use a high-atomization glue sprayer to apply urea-formaldehyde resin glue to the dried raw materials, with a sizing amount of 2%, and sizing The final moisture content is controlled at 8-10%. The shavings after sizing are paved with a mechanical paving machine, and the slab is pre-pressed with a pressure of 0.1MPa to prepare a board with a density of 0.25g / cm 3 lightweight particleboard. Under...

Embodiment 2

[0024] Repeat Example 1, with the following differences: 10 mesh but 20 mesh shavings are selected; the test results are shown in Table 1.

Embodiment 3

[0026] Repeat Example 1, with the following differences: choose 20 mesh but 30 mesh scraps; the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com