Compound tissue engineering scaffold containing PLGA (poly(lactic-co-glycolic acid) strengthening net, and preparation method and application thereof

A tissue engineering scaffold and reinforcing mesh technology, applied in medical science, prosthesis, surgery, etc., to achieve the effect of facilitating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation of embodiment 1PLGA reinforced net

[0059] Polylactic acid (LA) and polyglycolic acid (GA) monomers are mixed at a molar ratio of 1:1. After being fully mixed, the bulk is mixed at a high temperature. After being melt-spun into a thread, the PLGA reinforced mesh is woven. The PLGA reinforced mesh has a thickness of 200-3000 μm. The diameter of a single PLGA braided wire is between 10 and 200 μm; the mesh is cleaned with acetone, ultrasonically cleaned with pure water, and vacuum heat-set to obtain a PLGA reinforced mesh.

[0060] The above-mentioned polylactic acid (LA) and polyglycolic acid (GA) monomers can also choose any component ratio of 1:1 to 1:99 by mole.

Embodiment 2

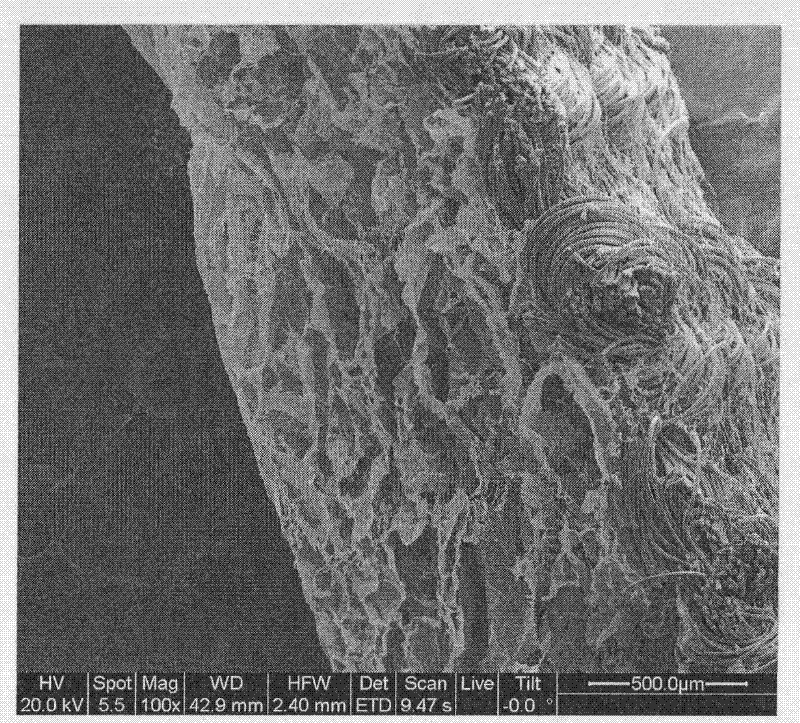

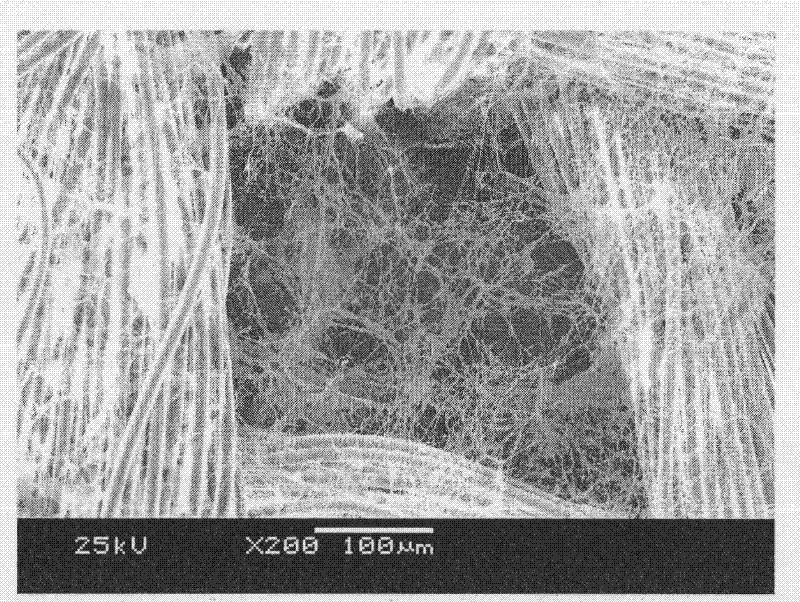

[0061] Example 2 Ultrastructural Observation of the Composite Tissue Engineering Scaffold Containing PLGA Reinforcing Net under Scanning Electron Microscope

[0062] Collagen and chitosan were made into 0.5% acetic acid solution with a mass fraction of 0.5%, then the collagen solution and chitosan solution were mixed according to the volume ratio of 9:1, fully stirred evenly, and set aside; the PLGA reinforced net was cut into 4.5cm ×4.5cm in size, spread it flat on the flat plate, and then press a “frame” mold with a thickness of 1cm and a size of 4cm×4cm tightly on the net, and then inject 3.2mL of collagen / chitosan solution to make it evenly Infiltration of PLGA reinforced mesh; place PLGA reinforced mesh, collagen / chitosan solution together with the mold at 4°C for 24 hours, freeze at -20°C for 24 hours, and then freeze-dry in a freeze dryer for 16 hours; freeze-dry The composite scaffold was cross-linked under vacuum dry heat at 105 °C for 24 hours, and then cross-linked ...

Embodiment 3

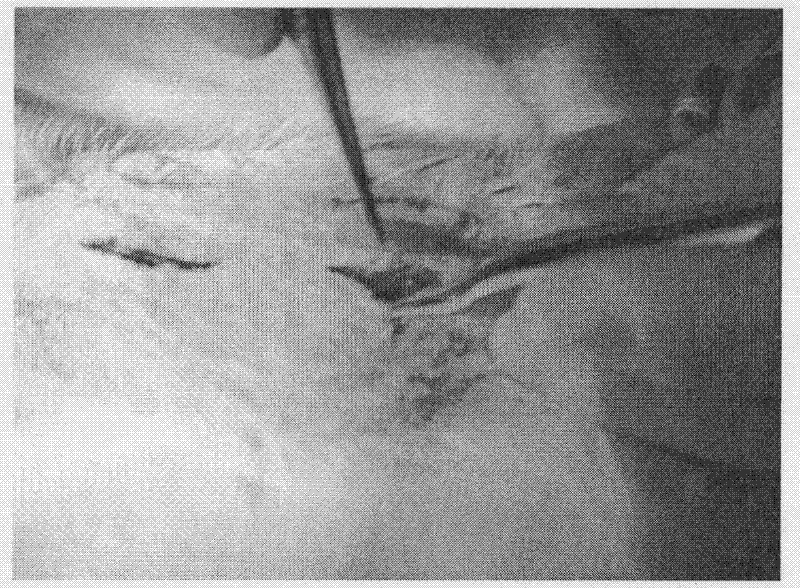

[0064] Example 3 In vivo implantation experiment of composite tissue engineering scaffold containing PLGA reinforcement mesh

[0065] Collagen and chitosan were made into 0.5% acetic acid solution with a mass fraction of 0.5%, then the collagen solution and chitosan solution were mixed according to the volume ratio of 9:1, fully stirred evenly, and set aside; the PLGA reinforced net was cut into 4.5cm ×4.5cm in size, spread it flat on the flat plate, and then press a “frame” mold with a thickness of 1cm and a size of 4cm×4cm tightly on the net, and then inject 3.2mL of collagen / chitosan solution to make it evenly Infiltration of PLGA reinforced mesh; place PLGA reinforced mesh, collagen / chitosan solution together with the mold at 4°C for 24 hours, freeze at -20°C for 24 hours, and then freeze-dry in a freeze dryer for 16 hours; lyophilize The composite scaffold was cross-linked under vacuum dry heat at 105 °C for 24 hours, and then cross-linked in a mixed solution of EDAC (40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com