Method for preparing alkali-activated coal gangue concrete from coal gangue mainly

A coal gangue concrete and main raw material technology, which is applied in the field of preparing alkali-activated coal gangue concrete with coal gangue as the main raw material, can solve the problem of low utilization rate of coal gangue, achieve significant environmental and social benefits, and alleviate the problem of non-renewable resources Consumption, the effect of alleviating high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

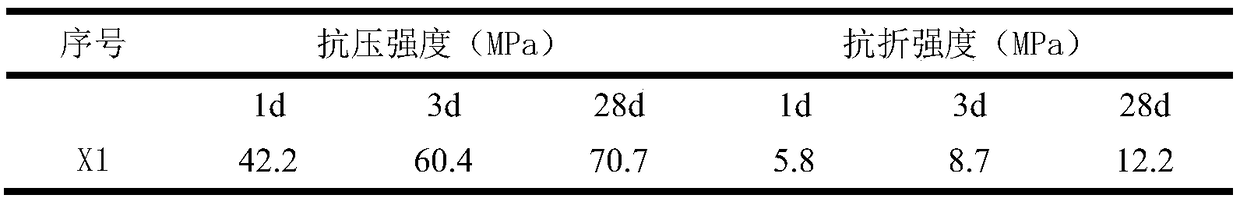

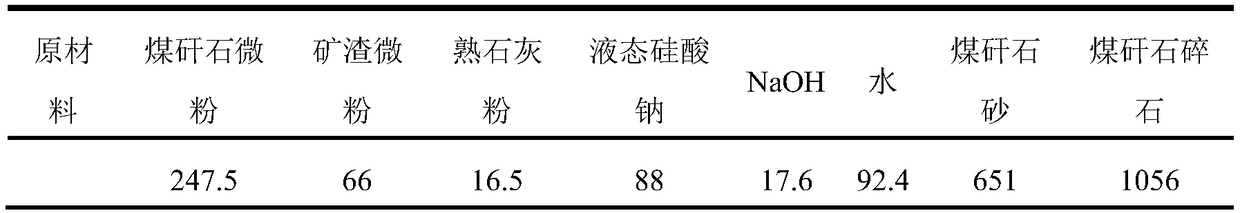

Embodiment 1

[0027] Embodiment 1: A method for preparing alkali-activated coal gangue concrete with coal gangue as the main raw material, which is characterized in that: firstly, the coal gangue block is crushed, and then screened. The coal gangue particles with a particle size of less than 0.15mm after crushing are further ball-milled and made into coal gangue micropowder to make the specific surface area ≥ 350m 2 / kg, and ultra-fine coal gangue powder with a particle size of less than 50 μm accounts for more than 90% of the total mass, which is used to prepare the cementitious material of alkali-activated coal gangue concrete. The coal gangue particles with a particle size greater than 0.15mm and less than 0.5mm are further screened and configured into continuous gradation to prepare fine aggregates of the alkali-activated gangue concrete. The coal gangue block whose particle size is greater than 0.5mm and less than 30mm is further screened and configured into continuous gradation, so as ...

Embodiment 2

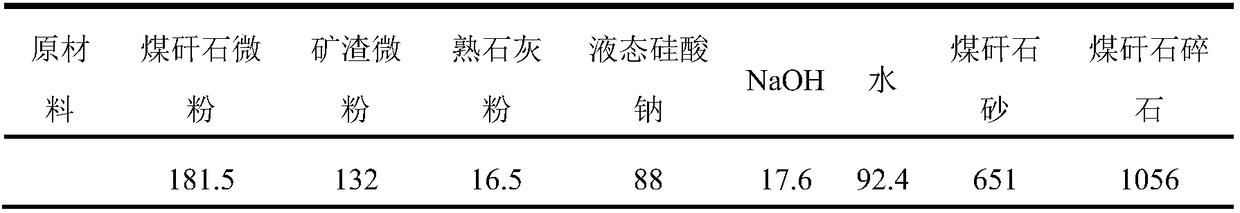

[0034] Embodiment 2: preparation method is identical with embodiment 1, omission. The difference is: the composition of the alkali-activated coal gangue concrete material and its mass percentage are as follows: the cementitious material is 55% of ground coal gangue micropowder (amount of 181.5kg / m 3 ); blast furnace granulated slag powder 40% (dosage 132kg / m 3 ); ground slaked lime powder 5% (dosage 16.5kg / m 3 ); the fine aggregate is coal gangue sand (amount 651kg / m 3 ); the coarse aggregate is coal gangue crushed stone (amount 1056kg / m 3 ); liquid sodium silicate with a modulus of 2.75 (dosage 88kg / m 3 ); caustic soda (NaOH dosage 17.6kg / m 3 ); water (amount 92.4kg / m 3 );

[0035] Table 3 Test mix ratio kg / m 3

[0036]

Embodiment 3

[0037] Embodiment 3: preparation method is identical with embodiment 1, omission. The difference is: the composition of the alkali-activated coal gangue concrete material and its mass percentage are as follows: the cementitious material is 35% of ground coal gangue micropowder (amount of 115.5kg / m 3 ); blast furnace granulated slag powder 60% (dosage 198kg / m 3 ); ground slaked lime powder 5% (dosage 16.5kg / m 3 ); the fine aggregate is coal gangue sand (amount 651kg / m 3 ); the coarse aggregate is coal gangue crushed stone (amount 1056kg / m 3 ); liquid sodium silicate with a modulus of 2.75 (dosage 88kg / m 3 ); caustic soda (NaOH dosage 17.6kg / m 3 ); water (amount 92.4kg / m 3 );

[0038] Table 4 Test mix ratio kg / m 3

[0039]

[0040] Table 5 Properties of coal gangue concrete stimulated by alkali with different mix ratios

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com