Preparation method of alkali lignin modified polycarboxylic acid-type coal water slurry dispersant

A technology based on alkali lignin and polycarboxylic acid is applied in the field of preparation of coal-water slurry dispersant, which can solve the problems of complex synthesis process, high dispersant dosage, complex preparation process, etc., and achieve simple production process, wide sources, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

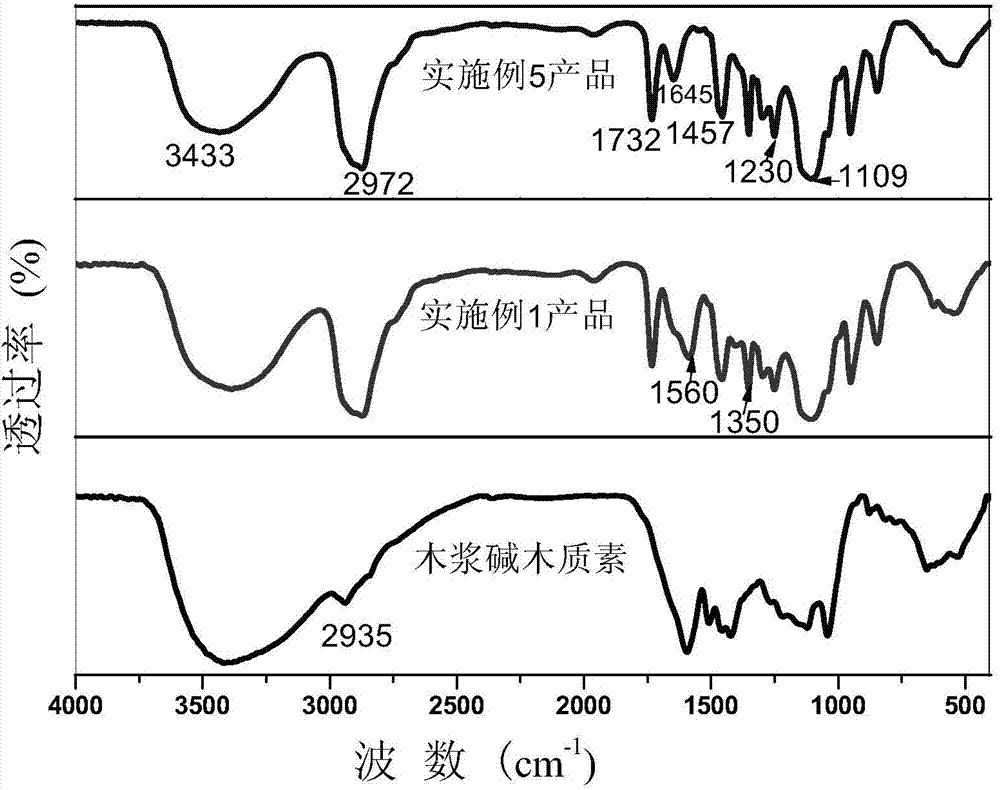

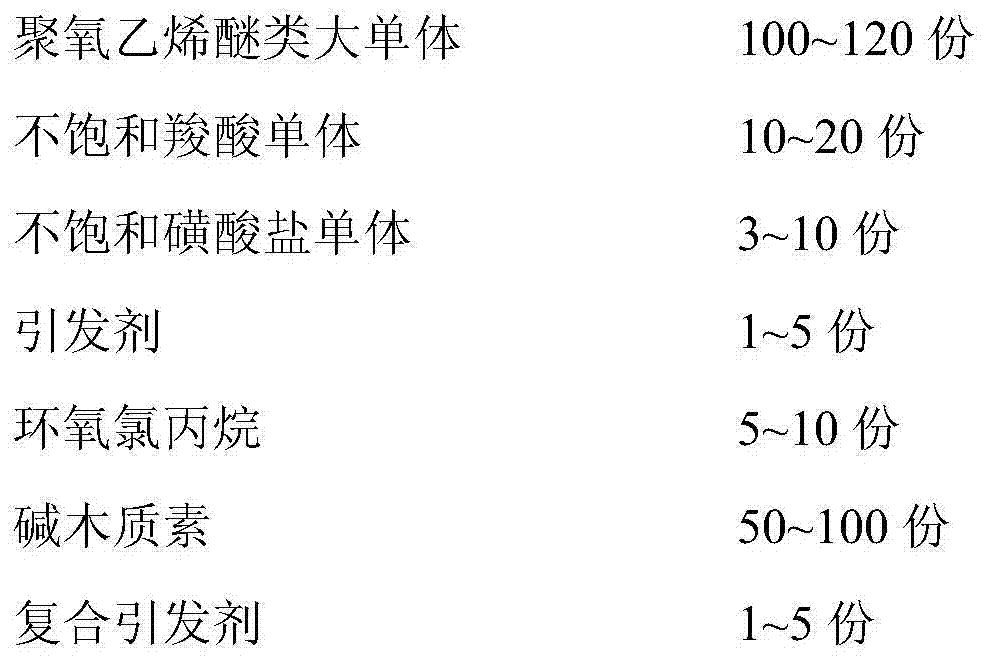

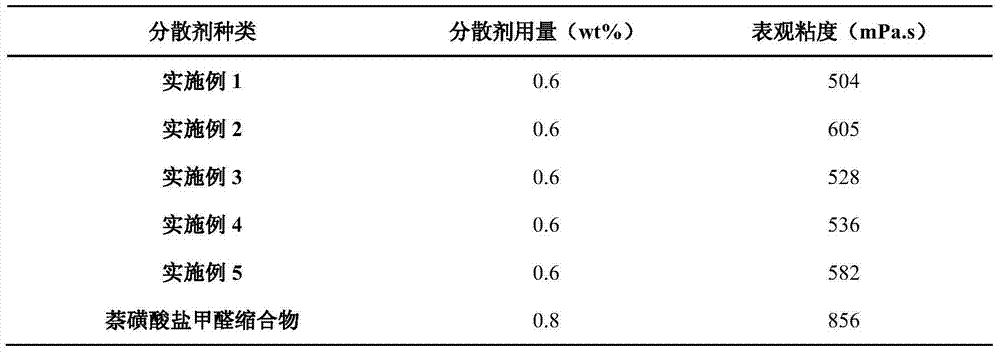

Embodiment 1

[0031] Dissolve 120g of methylbutenol polyoxyethylene ether, 3g of sodium 2-acrylamide-2-methylpropanesulfonate, and 18g of acrylic acid in water to prepare an aqueous solution with a mass concentration of 50%. When the temperature rises to 75°C, drop Add an aqueous solution with a mass concentration of 2% formed by 2g of initiator potassium persulfate, add dropwise for 2h, continue to keep warm for 2h after the dropwise addition, adjust the temperature to 45°C, add 6g of epichlorohydrin, and react for 0.5h. It is 11 to regulate pH with the NaOH that mass concentration is 30%, add the mass concentration that is made in the aqueous solution that is 11 by 80g wood pulp alkali lignin and be made into in the aqueous solution that pH is 11, be warming up to 75 ℃, add dropwise by 2g The mass solubility that potassium sulfate, 1g sodium sulfite is made into is the aqueous solution of 2%, reacts 2.5h, and the alkali lignin modified polycarboxylate high-efficiency coal-water slurry disp...

Embodiment 2

[0033] Dissolve 100g polyethylene glycol monomethyl ether, 6g sodium methacrylate, and 10g maleic anhydride in water to prepare an aqueous solution with a mass concentration of 50%. After the temperature rises to 50°C, add 2g of initiator dropwise Potassium sulfate is made into an aqueous solution with a mass concentration of 2%, and the dropwise addition time is 2h. After the dropwise addition, continue the heat preservation reaction for 2h, adjust the temperature to 50°C, add 6g of epichlorohydrin, and react for 0.5h with a mass concentration of 30%. NaOH is used to adjust the pH to 10, adding an aqueous solution having a mass concentration of 30% formed by dissolving 60g reed alkali lignin in an aqueous solution having a pH of 10, raising the temperature to 70°C, adding 2g ammonium cerium nitrate, 1g ammonium persulfate dropwise Prepare an aqueous solution with a mass solubility of 2%, react for 2 hours, and obtain an alkali-lignin modified polycarboxylic acid-based high-eff...

Embodiment 3

[0035] Dissolve 120g of propylene alcohol polyoxyethylene ether, 8g of sodium styrene sulfonate, and 12g of methacrylic acid in water to prepare an aqueous solution with a mass concentration of 50%. After the temperature rises to 80°C, add 3g of initiator ammonium persulfate dropwise Prepare the aqueous solution with a mass concentration of 2%, add it dropwise for 2 hours, continue to keep warm for 2 hours after the dropwise addition, adjust the temperature to 40°C, add 8g of epichlorohydrin, react for 1 hour, and adjust with NaOH with a mass concentration of 30%. When the pH is 12, add an aqueous solution with a mass concentration of 30% prepared by dissolving 90g of bamboo alkali lignin in an aqueous solution with a pH of 12, heat up to 80°C, and add dropwise a mixture of 2g of ammonium persulfate and 1g of sodium thiosulfate. The mass solubility is 2% aqueous solution, react for 2 hours, and the alkali lignin modified polycarboxylate high-efficiency coal-water slurry dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com