A preparation method of a modified polyvinyl alcohol copolymer cross-linked ceramic green body reinforcing agent

The technology of polyvinyl alcohol copolymer and ceramic body is applied in the field of ceramic body reinforcing agent, which can solve the problems of increasing the viscosity of the body slurry, pollution, and reducing the yield of finished products, so as to increase the strength of the green body and have a broad application prospect. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

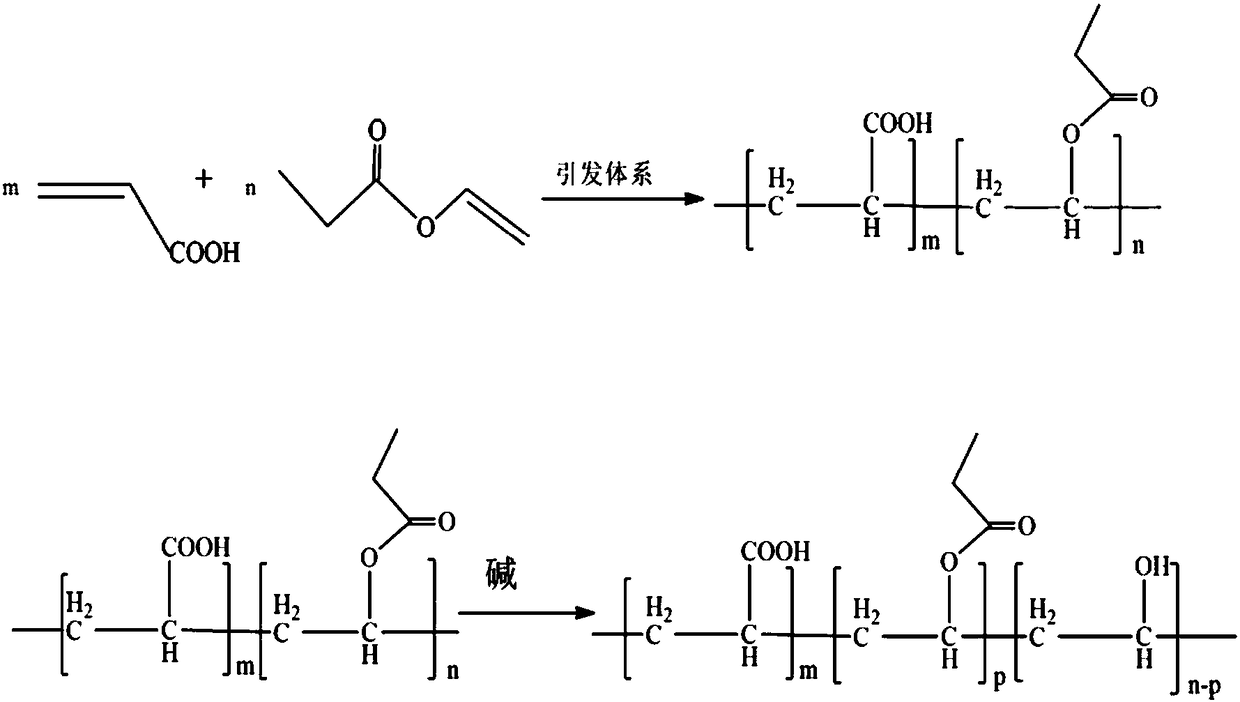

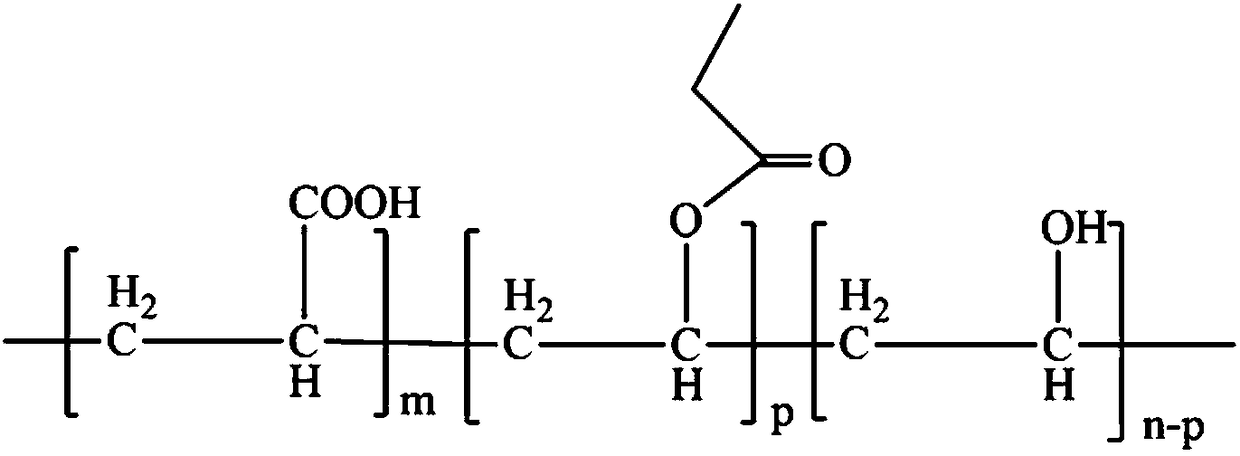

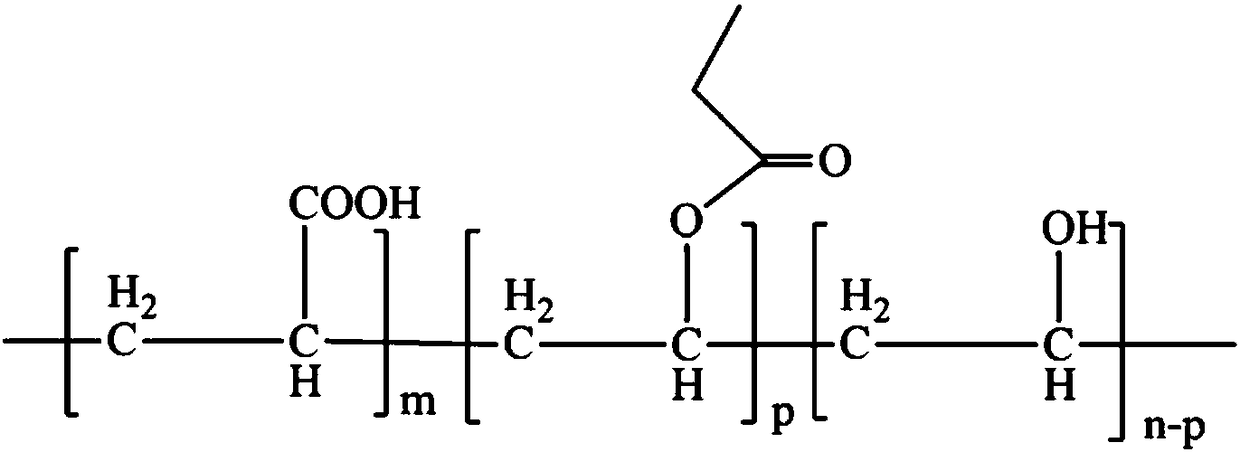

Method used

Image

Examples

Embodiment 1

[0026] a. Add 100 parts (by mass) of vinyl acetate and 42 parts of acrylic acid into the reactor, add 50 parts of ethanol and stir to completely dissolve the monomers and obtain a mixed solution I;

[0027] b. Add 1 part of sodium hypophosphite to the above mixed solution I, stir and fully dissolve to obtain mixed solution II, and heat the mixed solution II to 90°C;

[0028] c. Dissolve 0.5 parts of ammonium persulfate in water, and add the solution dropwise to the mixed solution II, and react at 90°C for 4 hours to obtain the mixed solution III;

[0029] d. Add 5 parts of sodium hypophosphite to the mixed solution III, and at the same time add sodium hydroxide solution to adjust the pH of the system to 7, stop heating, and cool under stirring conditions to obtain a modified polyvinyl alcohol copolymer cross-linked ceramic Body enhancer.

[0030] According to the laboratory test, 0.4% of the reinforcing agent of the present invention is added to the ceramic standard formula s...

Embodiment 2

[0034] a. Add 100 parts (by mass) of vinyl acetate and 420 parts of acrylic acid into the reactor, add 500 parts of ethanol and stir to completely dissolve the monomers and obtain a mixed solution I;

[0035] b. Add 20 parts of sodium sulfite to the above mixed solution I, stir and fully dissolve to obtain mixed solution II, and heat mixed solution II to 60°C;

[0036] c. Dissolve 20 parts of potassium persulfate in water, and add the solution dropwise to the mixed solution II, and react at 60°C for 2 hours to obtain the mixed solution III;

[0037] d. Add 10 parts of sodium sulfite to the mixed liquid III, and at the same time add ammonia solution to adjust the pH of the system to 7, stop heating, and cool under stirring conditions to obtain a modified polyvinyl alcohol copolymer cross-linked ceramic body strengthening agent .

[0038] According to the laboratory test, 0.3% of the reinforcing agent of the present invention is added to the ceramic standard formula soil slurry...

Embodiment 3

[0042] a. Add 100 parts (by mass) of vinyl acetate and 200 parts of acrylic acid into the reactor, add 300 parts of ethanol and stir to completely dissolve the monomers and obtain a mixed solution I;

[0043] b. Add 8 parts of sodium bisulfite to the above mixed solution I, stir and fully dissolve to obtain mixed solution II, and heat mixed solution II to 80°C;

[0044]c. Dissolve 3 parts of ammonium persulfate in water, and add the solution dropwise to the mixed solution II, and react at 80°C for 3.5 hours to obtain the mixed solution III;

[0045] d. Add 8 parts of sodium hypophosphite to the mixed liquid III, and at the same time add potassium hydroxide solution to adjust the pH of the system to 8, stop heating, and cool under stirring conditions to obtain a modified polyvinyl alcohol copolymer cross-linked ceramic Body enhancer.

[0046] According to the laboratory test, 0.5% of the reinforcing agent of the present invention is added to the ceramic standard formula soil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com