Patents

Literature

41results about How to "Does not increase viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

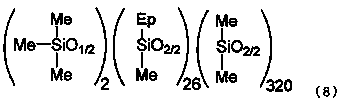

Siloxane-modified thermoplastic material and preparation method thereof

The invention relates to a method for preparing siloxane-modified thermoplastic material, which comprises the following steps: adding 100 weight parts of thermoplastic resin, 40-80 parts of high molecular weight siloxane, 20-40 parts of silicon resin, and 5-10 parts of compatibilizer into a blender, blending for 3-4min, then adding 10-25 weight parts of cross-linking agent and 0.01 -0.5 parts of hydrosilation catalyst, reacting and blending for 3-5min, discharging, cooling to the room temperature and obtaining a base stock; taking 100 weight parts of the base stock in the step one and 50-150 weight parts of thermoplastic resin for mixing uniformly, blending through an internal mixer or a double screw extruder and obtaining the siloxane-modified thermoplastic material. The cross-linking siloxane-modified thermoplastic material made by the invention has the advantages of higher heat resistance, excellent weather resistance, lower friction factor changing along with time, smooth surface, silk touch feeling and the like.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

High-performance rigid polyurethane foam material containing epoxide group

InactiveCN101831045AImprove high temperature resistanceImprove mechanical propertiesEpoxyOrganometallic catalysis

The invention relates to a rigid polyurethane foam material, in particular to a high-performance rigid polyurethane foam material containing epoxide group, which is characterized by being prepared by the reaction of the following components: isocyanate with 28-32wt% of NCO, polyalcohol compound with the OH value of 300-800, epoxy resin with the epoxy equivalent weight more than 100, catalyst compound, foam stabilizer and water, wherein the isocyanate component at least contains polyaryl polymethylene isocyanate; the polyalcohol compound at least contains polyalcohol component taking tolylenediamine as initiator; and the catalyst compound at least contains imidazole derivative catalyst, tertiary amine catalyst and organo-metallic catalyst. The rigid polyurethane foam material has high strength and super toughness as well good size stability, maintains excellent mechanical performance at higher temperature, and can be applied to wood-imitation material, filling material, thermal insulation material and the like.

Owner:BEIJING UNIV OF CHEM TECH

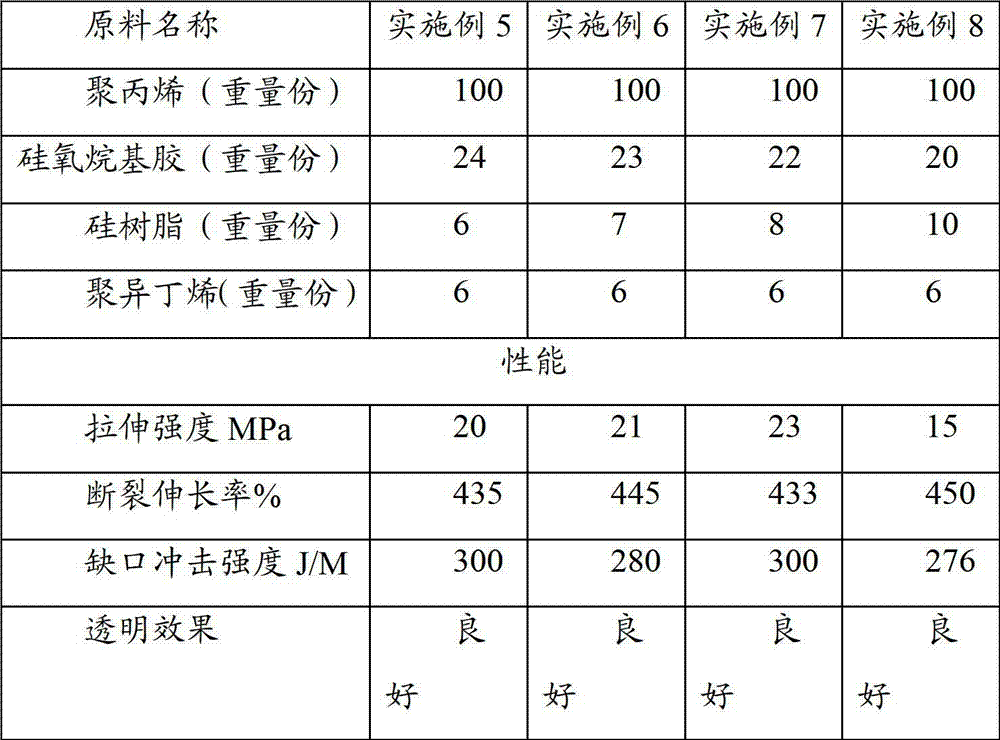

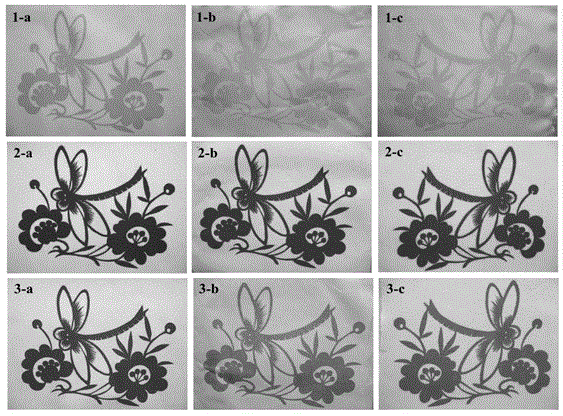

Dry-type transfer-printed textile and preparation method thereof

ActiveCN103774469AIncrease contentDoes not increase viscosityDyeing processWater dispersibleEnergy conservation

The invention relates to a dry-type transfer-printed textile and a preparation method of the dry-type transfer-printed textile. The method comprises the following steps: uniformly dispersing a water-dispersible hot melt adhesive into water so as to form a suspension; adding a printing thickener so as to regulate the viscosity of the suspension; adding printing auxiliaries such as acid, alkali and a hygroscopic agent according to the used dye, so as to prepare printing paste; coating a paper sheet or s film by use of the printing paste; drying and calendering, so as to obtain a paper sheet or film with the coating surface; performing printing treatment on the paper sheet or the film by use of a dye, so as to prepare transfer paper or a transfer film; hot-pressing and laminating the transfer paper or transfer film and a to-be-printed textile; performing color fixing, then stripping off the transfer paper or transfer film, and washing and sizing the textile after the color fixing, so as to obtain the printed textile. According to the printing method provided by the invention, wetting treatment of the textile is omitted, and transfer printing can be directly performed on the dry textile or a garment, so that the definition of printed patterns and the transfer stability of the dye are ensured; meanwhile, the operation sequence is simplified, emission of waste water of the printing and dyeing industry can be reduced, and the preparation method is beneficial to energy conservation and environment protection.

Owner:KAISHENG TEXTILE

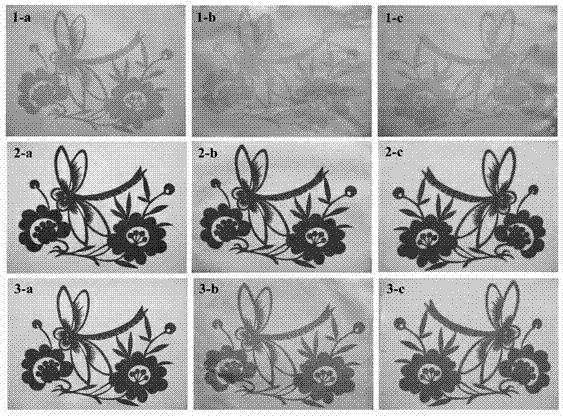

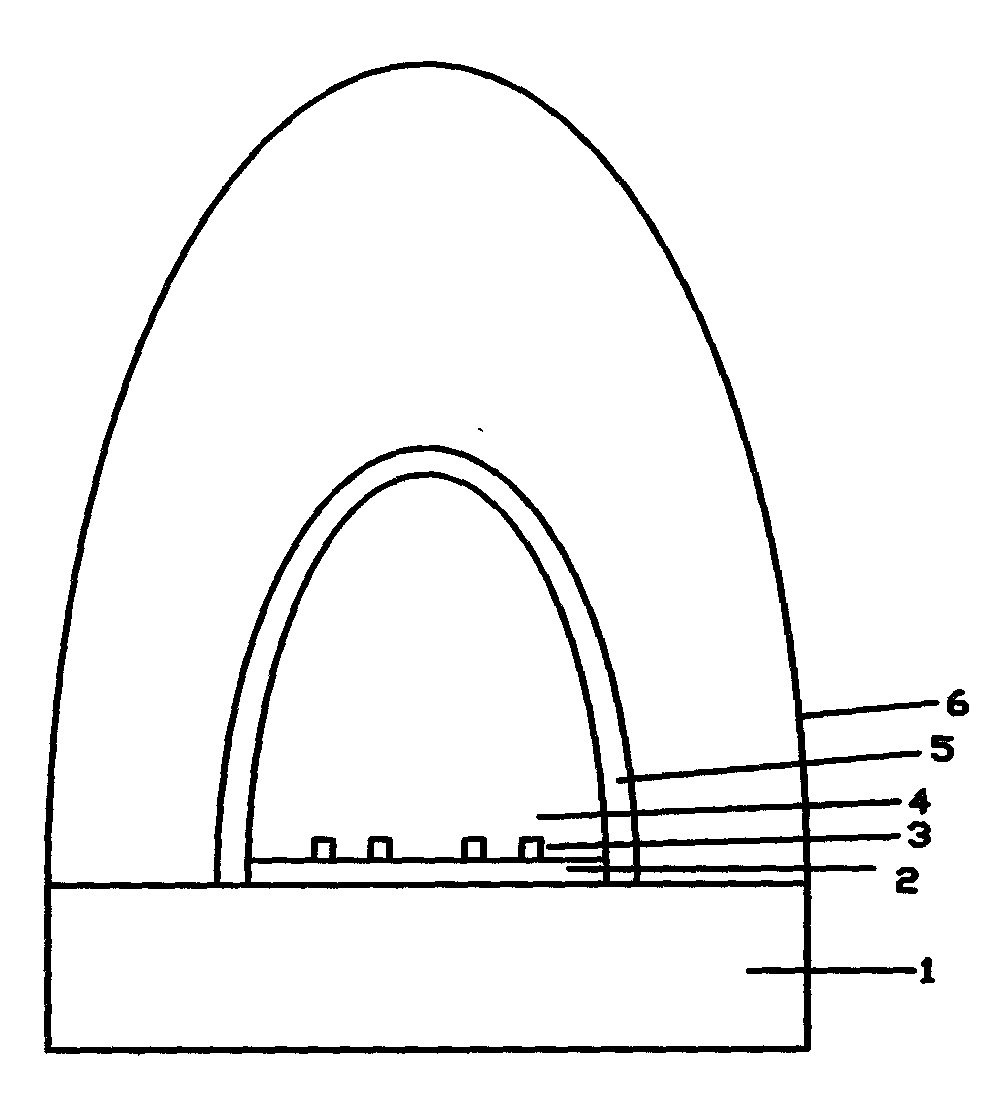

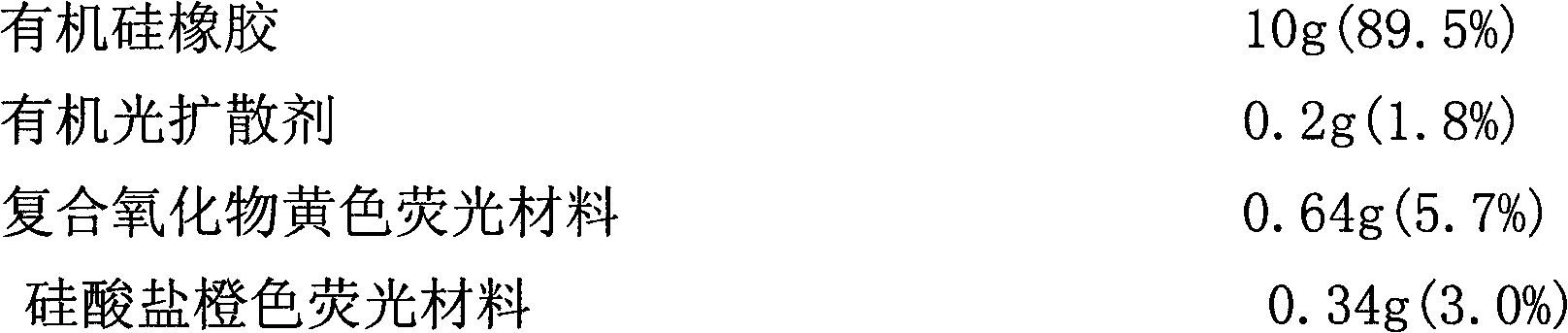

Light conversion module

InactiveCN102368496AIncrease the light output angleWell mixedSolid-state devicesSemiconductor devicesPhosphorScattering effect

The invention relates to a module possessing a light conversion function. An organic silicone rubber is taken as a carrier. An LED phosphor and an organic light diffuser agent are added to form the light conversion module. The module is soft and elastic. A preparation method is characterized by: mixing organic silicon glue, the LED phosphor and the organic light diffuser agent uniformity; injecting into a mould, heating, curing and molding. The module can be used in a blue ray LED light source. The LED phosphor can be excited to glow by the blue ray emitted by the blue ray LED light source, and through reflection, refraction and scattering effects of the organic light diffuser agent, the light of the LED phosphor and the blue ray which is not be absorbed are composited into the white light or the light with other colors. The light color and intensity of the obtained compound light distribute uniformly, and are soft without glare. The compound light can realize the wide-angle light and can be applied in LEC illumination and decorative lamps.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

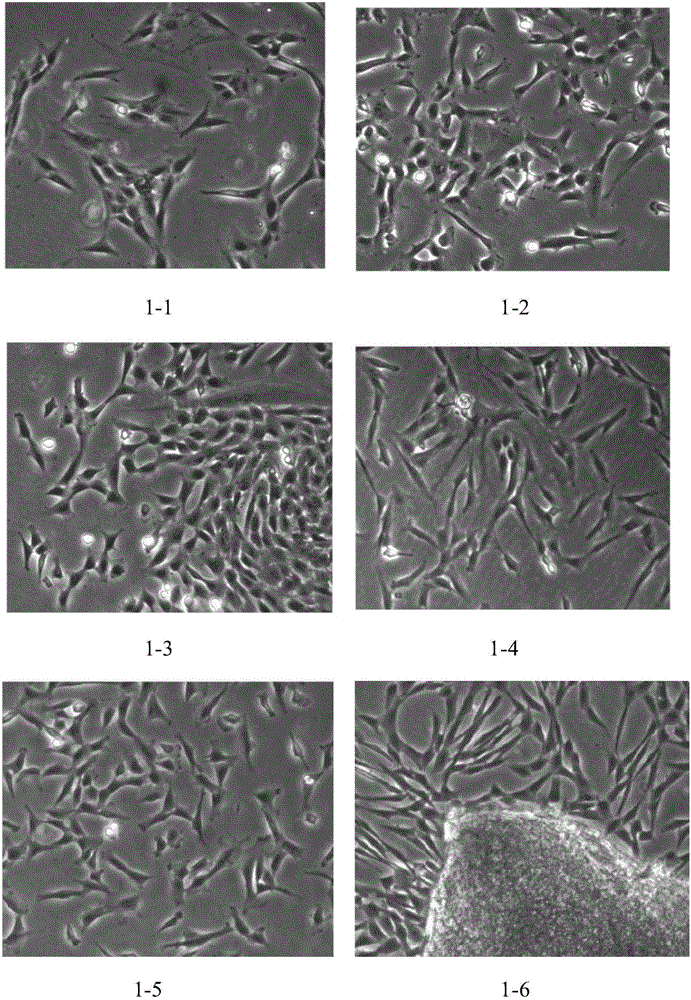

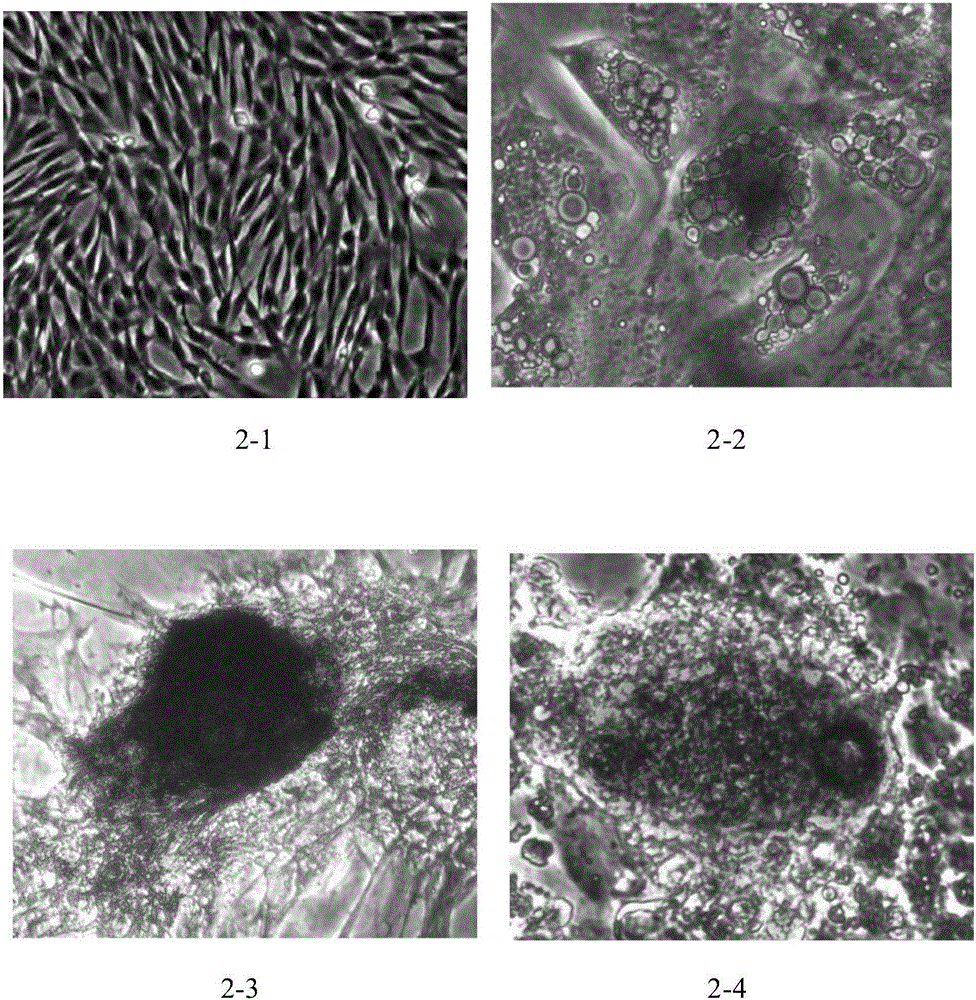

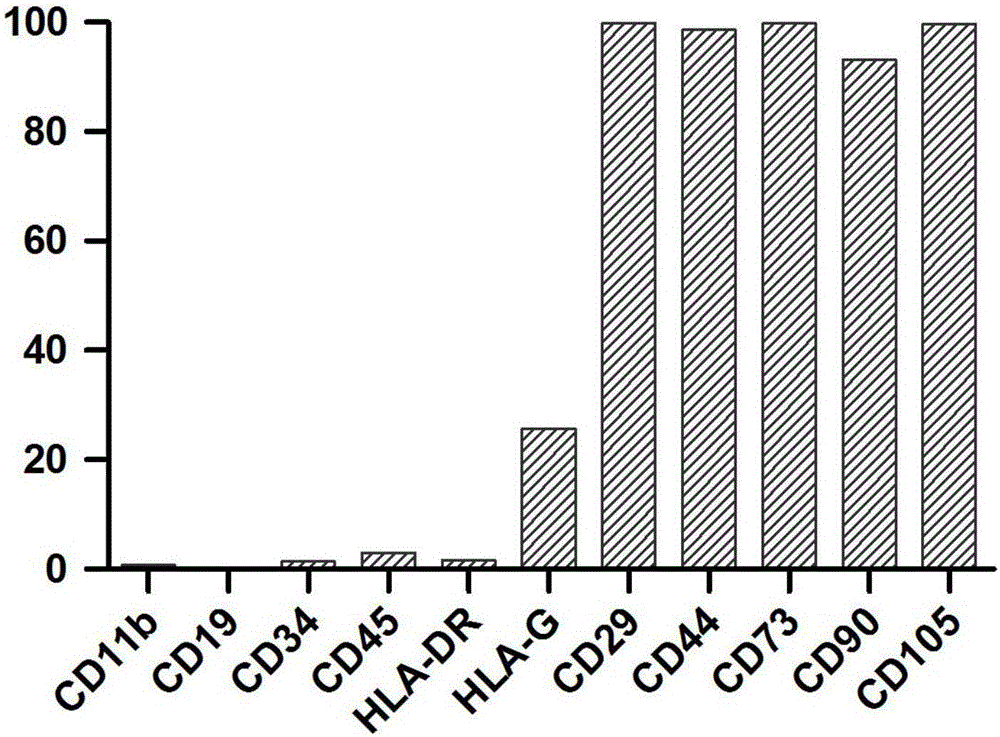

Placental villus plate mesenchymal stem cells and extraction method thereof

InactiveCN106085952APrevent intrusionReduce usageCell dissociation methodsSkeletal/connective tissue cellsFiltrationAntibiotic Y

The invention discloses placental villus plate mesenchymal stem cells. An extraction method of the placental villus plate mesenchymal stem cells includes the following steps that 1, a placental villus plate is obtained; 2, blood vessels and villus tissue are removed; 3, the villus plate is cleaned till the blood color disappears; 4, the villus plate is sheared into 0.5-5 mm<2> tissue microblocks, and the tissue microblocks are cleaned; 5, tissue digestive juice containing pancreatin, collagenase II, collagenase IV and hyaluronidase is added for digestion; 6, filtration and centrifugation are carried out; 7, culture is carried out; 8, cell digestion is carried out with 0.25% pancreatin when the cell confluence reaches 70-90%; 9, subculturing is carried out; 10, detection is carried out; 11, cryopreservation is carried out; 12, database building is carried out. According to the method, the steps are simple, and a large number of mesenchymal stem cells can be rapidly obtained from the placental tissue; the separation process does not need too much cleaning operation; the use of antibiotics is omitted, so that the purity of the placental villus plate mesenchymal stem cells obtained after separation is high.

Owner:四川华皓生物科技有限公司

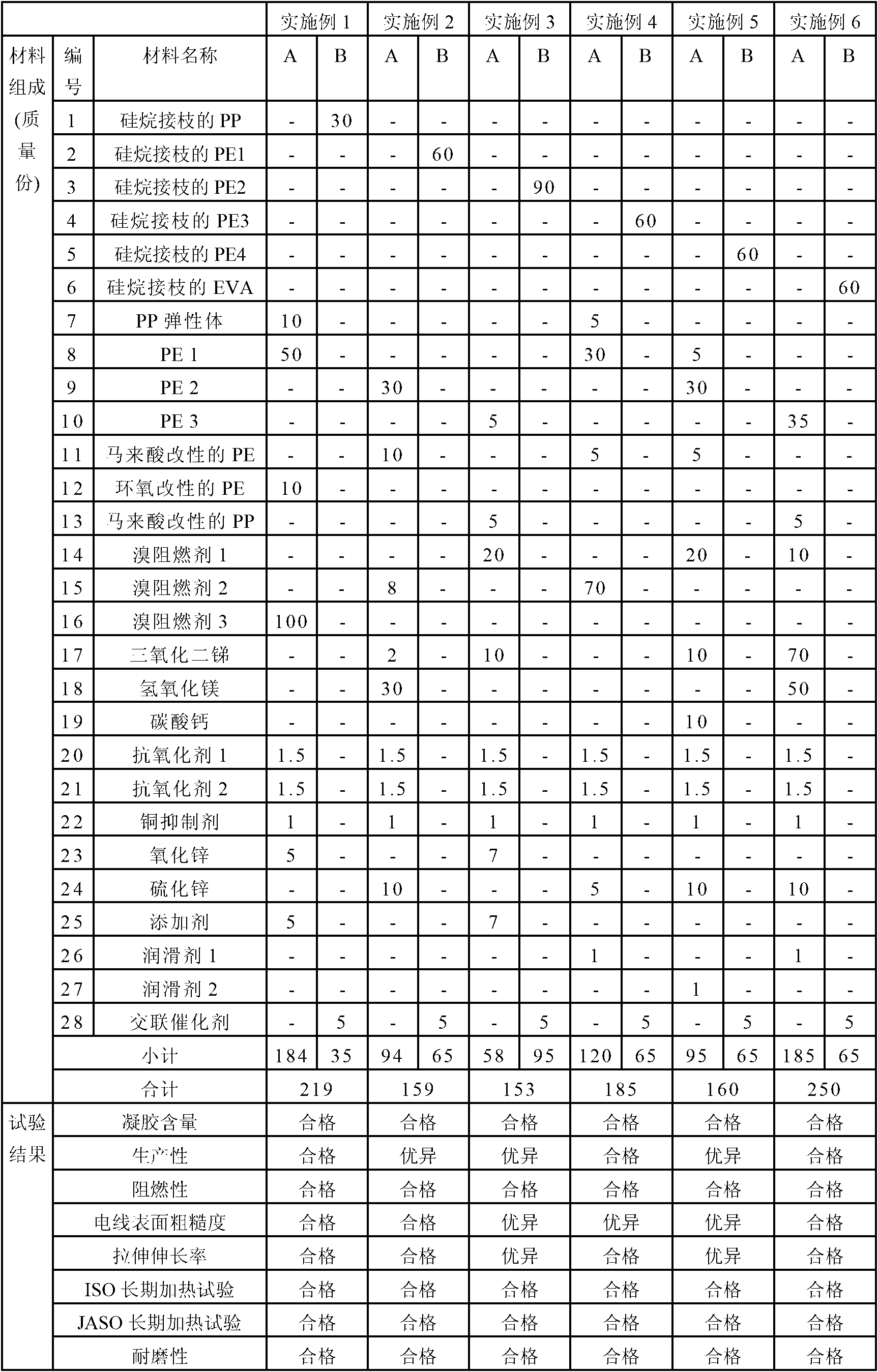

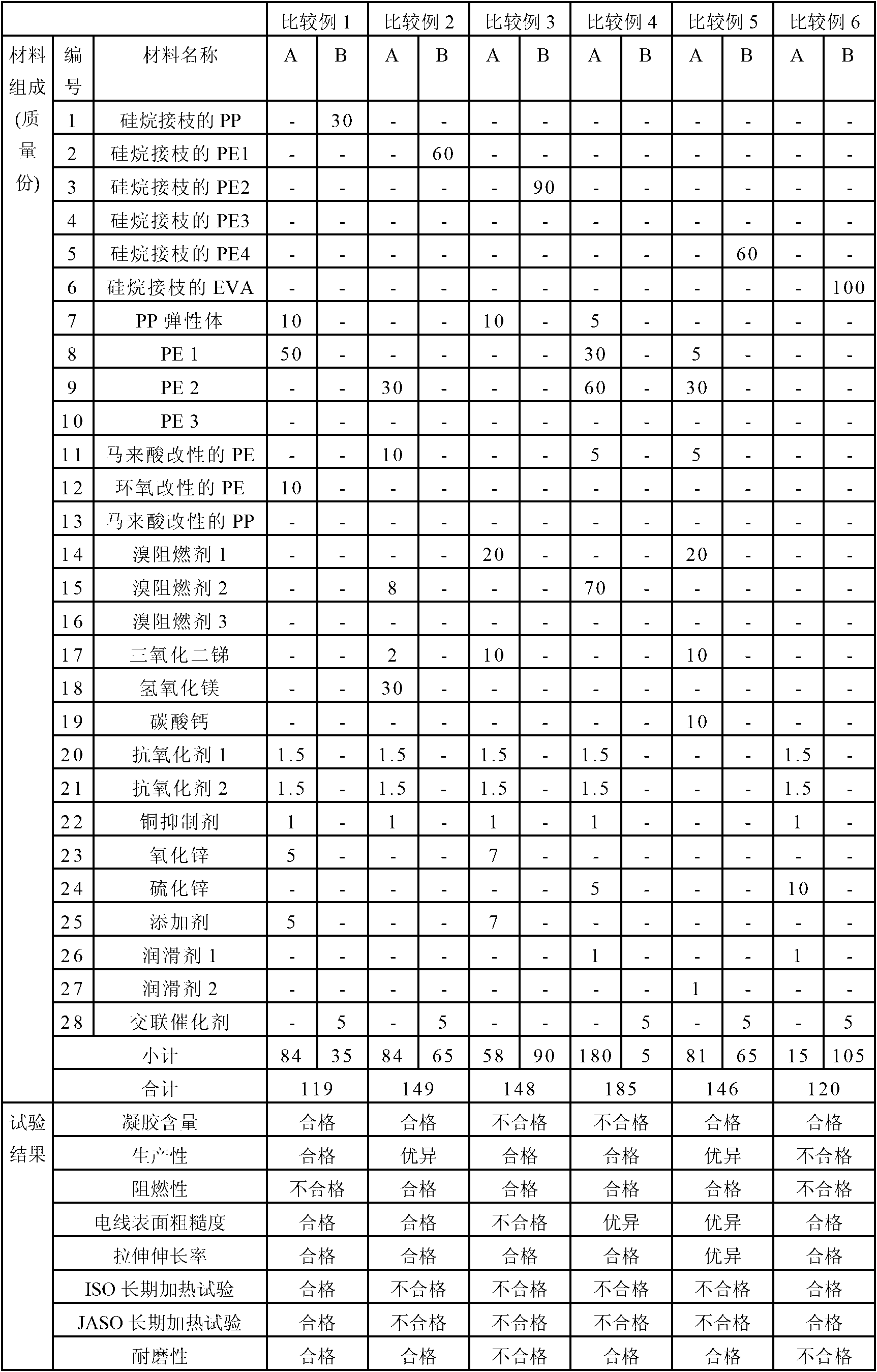

Composition for use in wire coating material, insulated wire and wire harness

ActiveCN102762650AImpossible to reduce heat resistanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesPolyolefinElectrical conductor

Disclosed are a composition for use in a wire coating material, an insulated wire and a wire harness. The disclosed composition achieves excellent heat resistance, good productivity, and flame resistance without using electron beam crosslinking. After the composition for use in a wire coating material is extrusion molded around a conductor to form the coating material, and water crosslinking is performed to create the insulated wire. The composition for wire coating material contains (A) water crosslinked polyolefins formed by modifying a polyolefin with a silane coupling agent, (B) unmodified polyolefins, (C) modified polyolefins modified with functional groups, (D1) a brominated flame retardant, (E) a crosslinking catalyst, (F) a phenolic antioxidant, and (G) (G1) a zinc sulphide or (G2) a zinc oxide-imidazole compound.

Owner:AUTONETWORKS TECH LTD +2

Structured acrylate copolymer for use in multi-phase systems

InactiveCN103379889AAcceptable rheologyDoes not increase viscosityCosmetic preparationsHair cosmeticsPersonal careCLARITY

Disclosed are multi-staged acrylic based core-shell polymers comprising a linear core polymer and at least one subsequently polymerized shell polymer. At least one of the subsequently polymerized shell polymers is crosslinked. The core-shell polymers surprisingly provide desirable rheological, clarity, and aesthetic properties in aqueous surfactant containing compositions, particularly at low pH. The multi-staged acrylic base core-shell polymers can be included in at least one phase of a multi-phase personal care, home care, health care, and institutional and industrial care composition to impart phase stability thereto.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Culture medium prescription for the industrial production of rhamnolipid fermentation liquor

InactiveCN101173238AIncrease productionShort cycleBacteriaMicroorganism based processesChemistryCulture mediums

The invention relates to a culture medium recipe for commercial production of rhamnolipid fermentation liquid, which is characterized in coin oil 2-5%, carbamide 0.2-1.5%, molasses 15-20%, potassium chloride 0.05-1.0%, KH2PO40.05-1.2%, K2HPO40.05-1.5%, yeast extract 0.005-0.1%, compound microelements 0.005-0.01% and the rest element is water; the pH value of the invention is 6.5-7.5. The invention has the advantages of low cost, high rhamnolipid content in fermentation, and is suitable for commercial production of rhamnolipid.

Owner:DAQING VERTEX CHEM

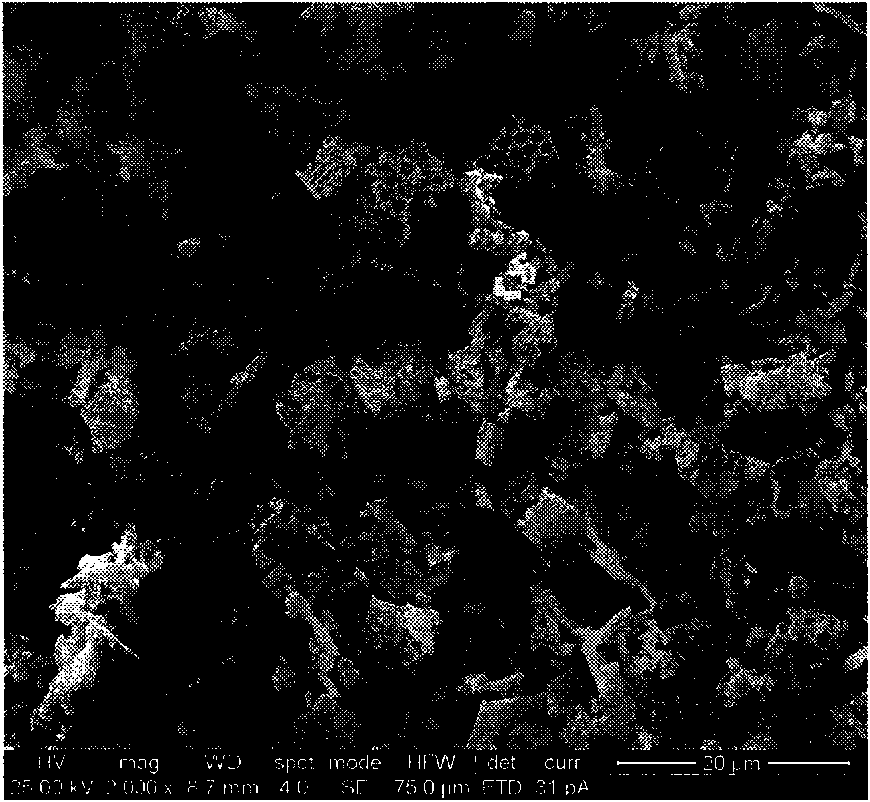

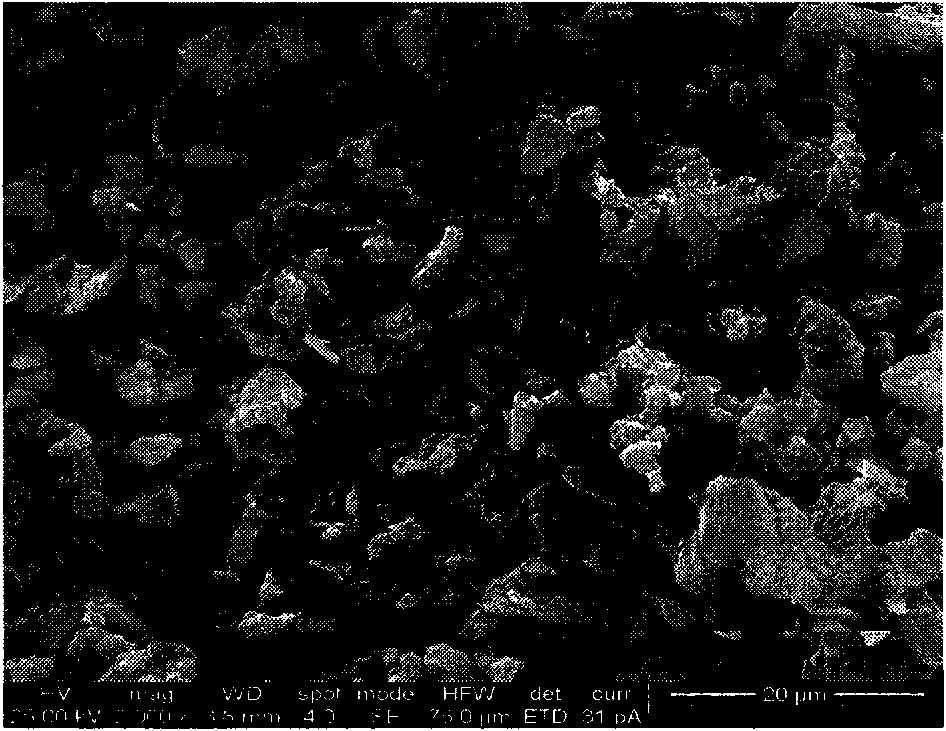

Preparation method of calcined diatomite flatting agent

ActiveCN101659796AImprove oil absorption capacityThickenCoatingsPigment treatment with macromolecular organic compoundsEmulsionGranularity

The invention relates to a preparation method of a calcined diatomite flatting agent, which is applicable to a water paint system of styrene-acrylate emulsion and pure acrylic emulsion and belongs tothe field of paint additive. The method has the steps of taking the diatomite with the weight percentage content of silicon dioxide being more than 85 wt% as the raw material, adding NaCl accounting for 2-4wt% of the diatomite and starch accounting for 6-8wt% of the diatomite, calcining with the temperature of 850-950 DEG C and the time of 2-3h, crushing by using jet milling technology after calcining with the feed particle size being 0.1-1mm and the discharging particle size being 0-40 mum, and obtaining the end product by classification after crushing, wherein the particle sizes after classification are distributed as follows: 1-8 mum: 39-44 wt%; 8-25 mum: 38-42 wt%; and 25-35 mum: 18-20 wt%. The calcined diatomite flatting agent does not increase the paint consistency, and the glossiness of the coating are very approximate at the incident angles of 60 degrees and 85 degrees.

Owner:BEIJING UNIV OF TECH +1

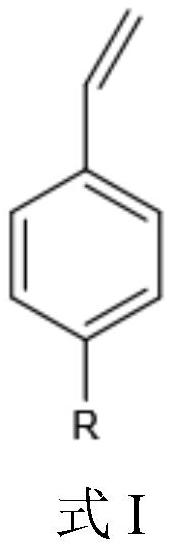

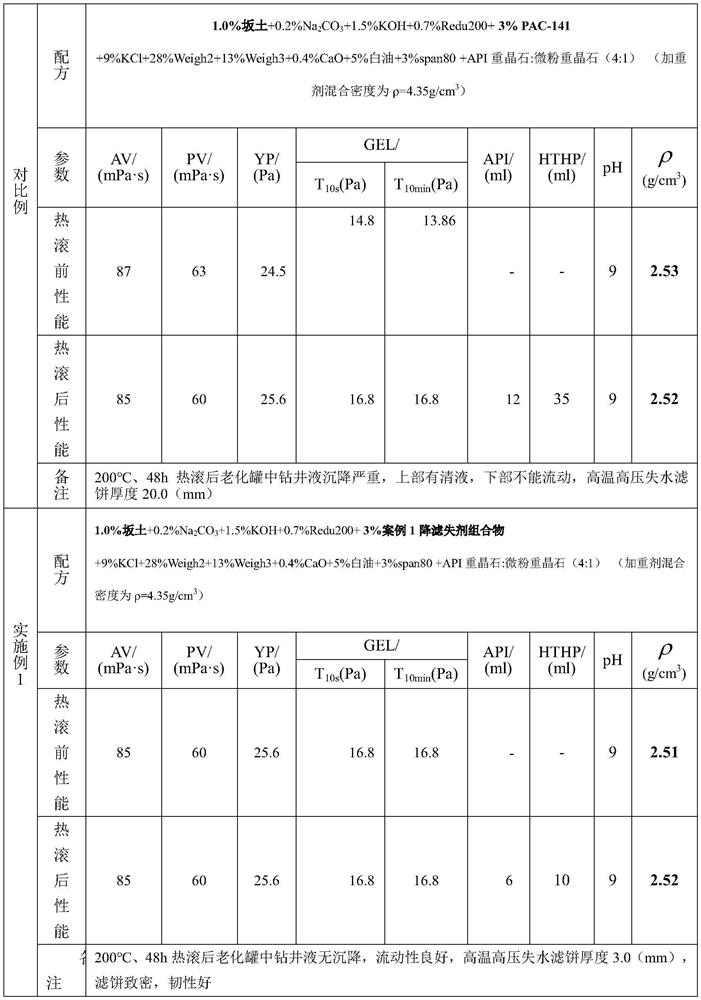

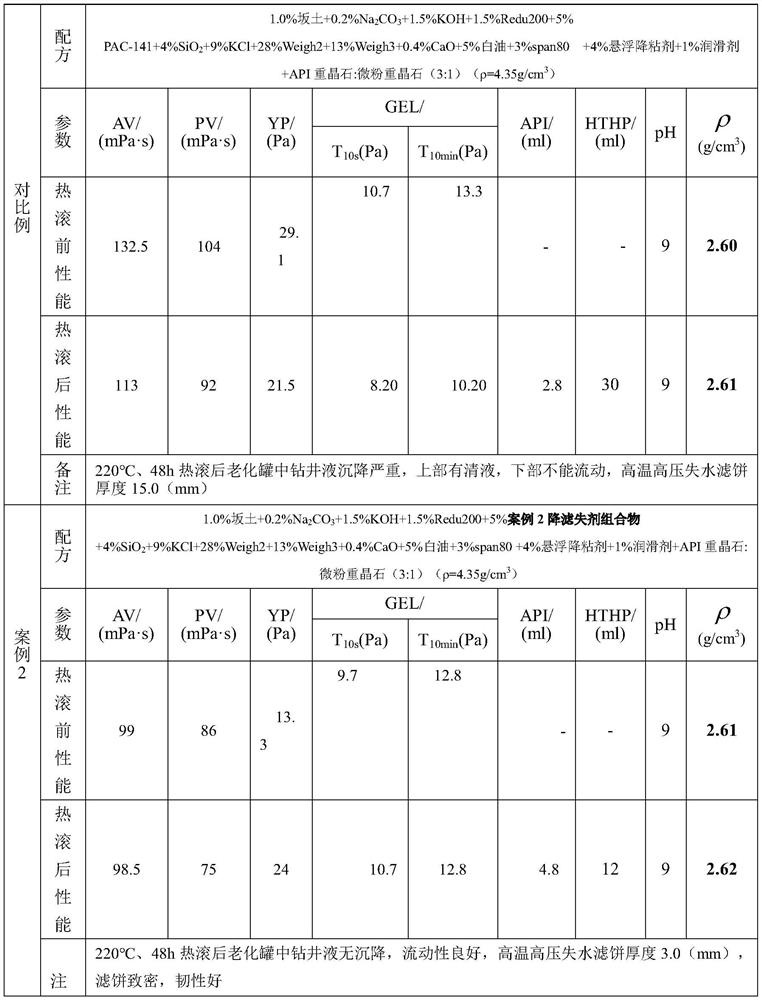

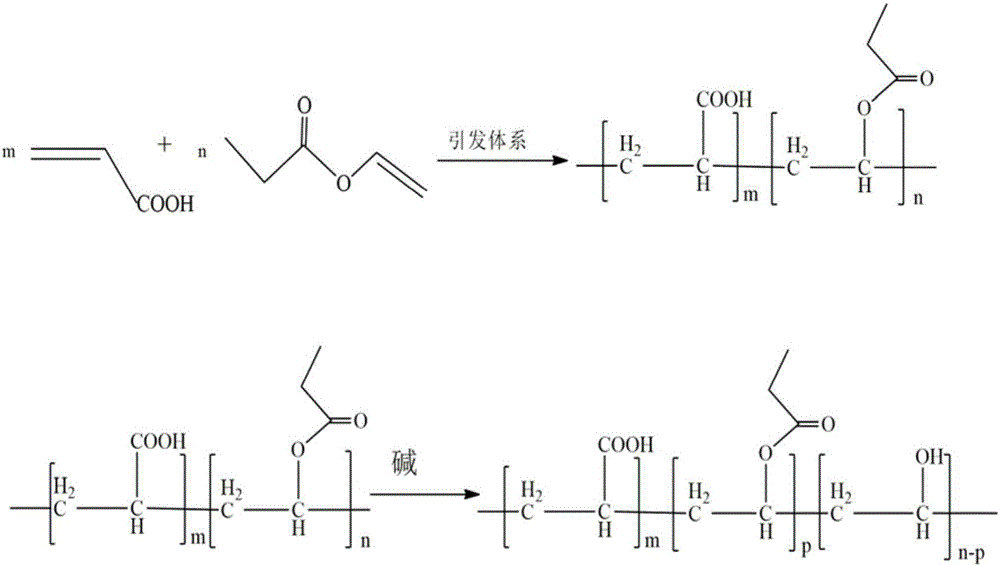

Preparation method of high-temperature high-density water-based drilling fluid filtrate reducer composition

PendingCN114736659AIncrease resistance to movementAvoid curlDrilling compositionHydrophilic monomerMicrosphere

The invention discloses a preparation method of a high-temperature and high-density water-based drilling fluid filtrate reducer composition, which belongs to the technical field of oilfield chemical agents, and is characterized in that the filtrate reducer composition is formed by combining a low-molecular-weight linear polymer and temperature-sensitive polymer particle microspheres, the preparation method of the low-molecular-weight linear polymer comprises the following steps: reacting an acrylamide hydrophilic monomer, a sulfonic acid group-containing temperature-resistant monomer, a rigid hydrophobic monomer, a cationic monomer, an initiator I and a polymerization inhibitor under a deoxidizing condition, washing a reaction product, drying and crushing to obtain the low-molecular-weight linear polymer. The preparation method of the temperature-sensitive polymer particle microspheres comprises the following steps: dissolving a temperature-sensitive monomer, a cationic monomer, a dispersing agent, a cross-linking agent and an initiator II in a mixed solution of deionized water and polyethylene glycol, reacting under a deoxidizing condition, and washing and drying a reaction product to obtain the polymer particle microspheres. The method is mainly used for synthesizing the high-temperature high-density water-based drilling fluid filtrate reducer composition.

Owner:YANGTZE UNIVERSITY +1

Meltable reinforced polyvinyl alcohol (PVA) composite and preparation method thereof

The invention discloses a preparation method of a meltable reinforced polyvinyl alcohol (PVA) composite, which comprises the following steps: (1) adding carbon nanotubes (CNT) into composite plasticizer containing a dispersion medium, stirring, and performing ultrasonic auxiliary dispersion for 1.5-4 hours to obtain a plasticizer solution; and (2) performing uniform incubation mixture on the plasticizer solution in the step (1) and a PVA resin to obtain the meltable CNT reinforced PVA composite. The invention also discloses the meltable reinforced PVA composite material prepared through the preparation method. According to the invention, the CNTs are dispersed in the plasticizer system for PVA; in the dispersion process, the viscosity of the disperse system can not be increased since no PVA is added; and on the premise of considering the economy, the amount of the CNTs can be increased as many as possible, thereby better realizing the reinforcement effect.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

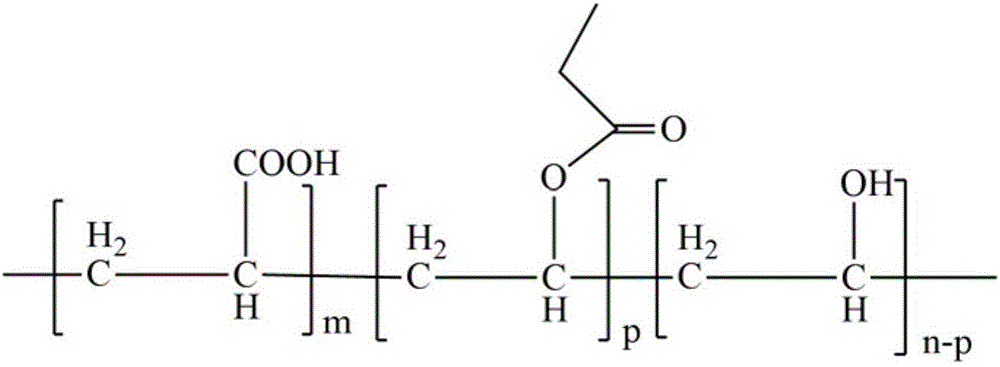

Method for preparing modified polyvinyl alcohol copolymer cross-linked ceramic green body reinforcing agent

The invention relates to a modified polyvinyl alcohol copolymer cross-linked ceramic green body reinforcing agent. Vinyl acetate and acrylic acid are subjected to a free-radical polymerization reaction in the presence of an initiator and a chain transfer agent, part of ester bonds of the copolymer are hydrolyzed when an alkali is added for treatment, and then, the acrylic acid and vinyl acetate modified polyvinyl alcohol copolymer ceramic green body reinforcing agent is prepared. The copolymer cross-linked ceramic green body reinforcing agent disclosed by the invention has relatively good dispersity, and the viscosity of slurry cannot be improved by adding the reinforcing agent into a ceramic slurry system; and during the forming of green body slurry, the slurry is completely hydrolyzed into an acrylic acid and vinyl alcohol copolymer under alkaline conditions, and hydroxyl groups of the copolymer are subjected to hydrogen bonding with particles in a green body, so that internal particles of the green body are of a reticular structure, the green strength, dried strength and glazed strength of the green body are greatly improved. The strength of the ceramic green body is greatly improved while the original adhesiveness, dispersity and viscosity reducing property of polyvinyl alcohol are kept, so that the reinforcing agent has a broad application prospect.

Owner:四会市奥耳新材料有限公司

Coagulant for cleaning polluted water or contaminated water

ActiveCN100361904CWon't breakAchieve protectionWater/sewage treatment by flocculation/precipitationAdditive ingredientSludge

To provide a coagulant for cleaning polluted water or contaminated water which is capable of enhancing a cohesive force, removing heavy metals and continuously treating polluted water or contaminated water in a short time and permits simply and efficiently the dehydration without exerting any effect to the natural environment. The coagulant for cleaning polluted water or contaminated water is prepared by uniformly dispersing a pH regulator, a density increasing agent and a chelate effect accelerator to a principal ingredient consisting of aluminum sulfate, calcium sulfate and sodium carbonate and mixing them. Cement can be used as the pH regulator and the cement or magnetic material can be used as the density increasing agent. Therein, ferrite can be used as the magnetic material. Further, the chelate effect accelerator comprising powders of iron, thio sodium oxide, chitosan and citric acid can be used.

Owner:长彰德 +3

Alloying steel-making technology by directly reducing molybdenum oxide in converter

InactiveCN107557516APrevent outflowDoes not increase viscosityManufacturing convertersProcess efficiency improvementSesquioxideSlag

The invention discloses an alloying steel-making technology by directly reducing molybdenum oxide in a converter. The alloying steel-making technology comprises the following steps that (1), molybdenum oxide powder, volatilizing inhibition agent powder, steel scraps and molten iron are prepared according to smelting requirements of 42CrMo steel; (2), the molybdenum oxide and a volatilizing inhibition agent are compressed and prepared into molybdenum raw material particles with the volume being 1-10 cm3; (3) the steel scraps and a part of the molybdenum raw material particles are added into themolten iron in the converter; and (4) smelting is conducted according to the smelting technology of the 42CrMo steel, the rest of the molybdenum raw material particles are added after blowing is conducted for 5 minutes. According to the alloying steel-making technology, a reducing agent does not need to be added additionally, molybdenum in the molybdenum sesquioxide can be reduced to a molybdenumsingle substance to enter the molten iron by utilizing iron and carbon in the molten iron, the molybdenum sesquioxide can be effectively prevented from sublimating and flowing out along with slag, the molybdenum yield is improved effectively, and the viscosity of molten steel cannot be increased to block a water port. In addition, compared with utilizing ferromolybdenum, the hardenability and thetensile strength are improved to some extent.

Owner:JIYUAN VOCATIONAL & TECHN COLLEGE

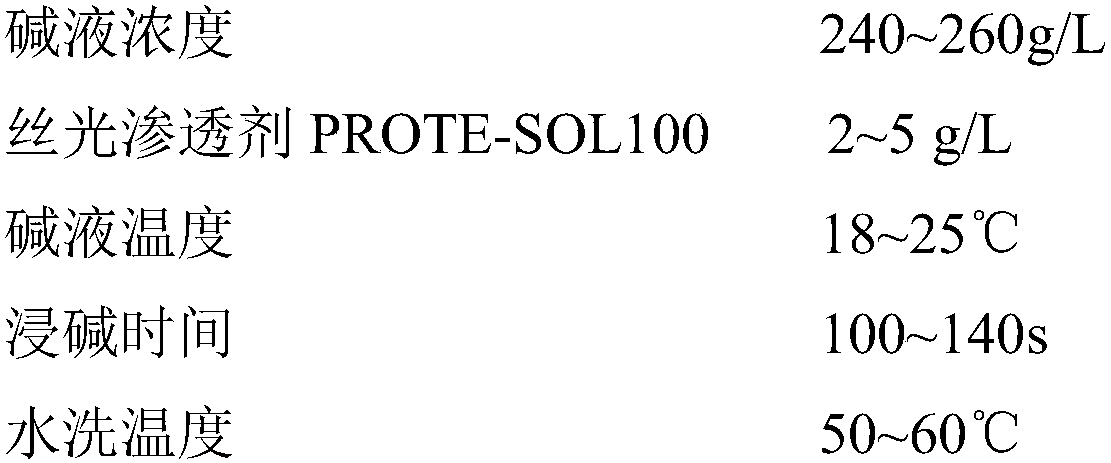

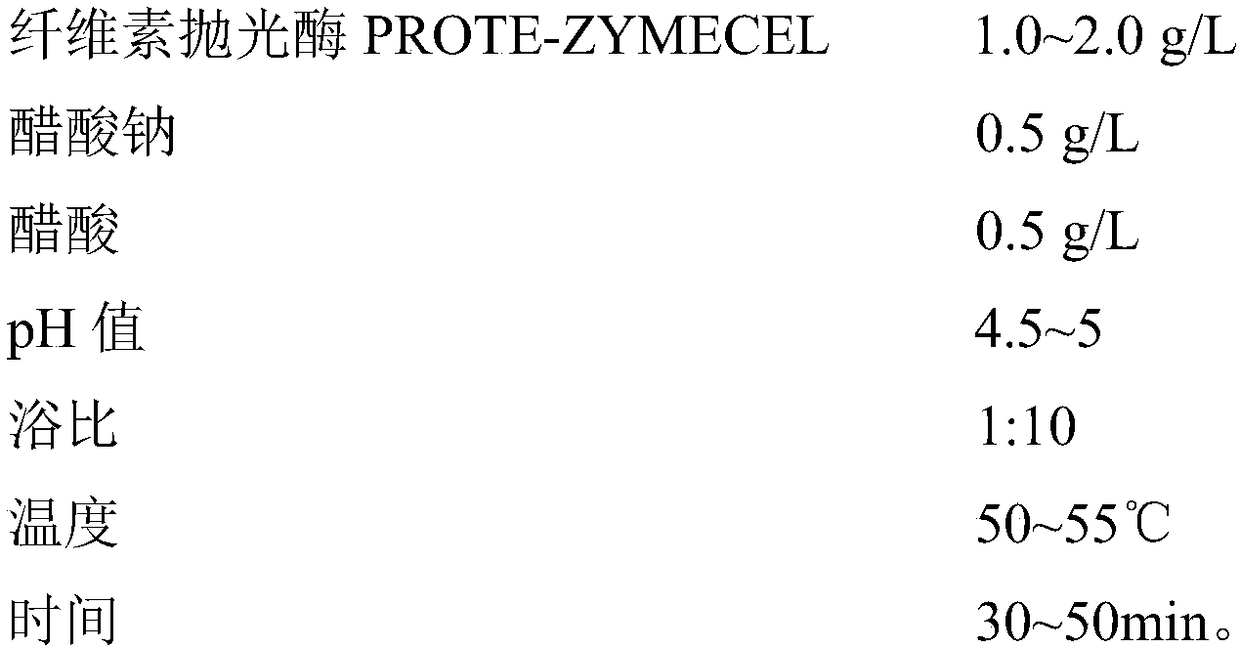

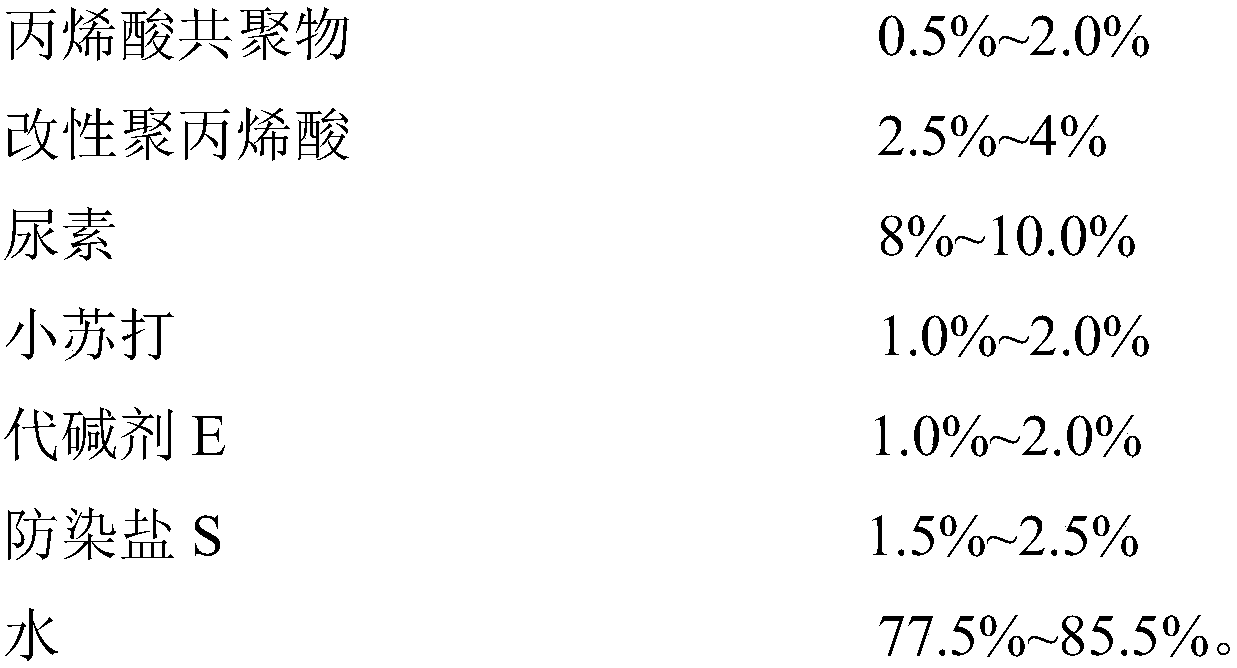

Active polymer dye ink and applications of active polymer dye ink in ink jet printing and dyeing process for cotton fabrics

ActiveCN108071023AIncrease profitReduce dosageMercerising of indefinite length fabricsOrganic dyesO carboxymethyl chitosanActive polymer

The invention provides an active polymer dye ink and applications of the active polymer dye ink in an ink jet printing and dyeing process for cotton fabrics. A purpose of the present invention is to solve the problems of low washing fastness and poor brilliance of the ink in the prior art. According to the present invention, the active polymer dye ink is prepared by carrying out a homogeneous grafting reaction on N,O-carboxymethyl chitosan as a polymeric dye skeleton and an active dye in an aqueous solution, wherein the active dye is formed by compounding an X-type active dye and a F-type active dye, and a molar ratio of the N,O-carboxymethyl chitosan to the active dye is 7-4:1; and the active dye molecules are grafted onto the skeleton of the N,O-carboxymethyl chitosan, such that the migration and the penetration of the active dye molecules are less so as to provide excellent performances of no toxicity, safety and convenient use.

Owner:浙江海印数码科技有限公司

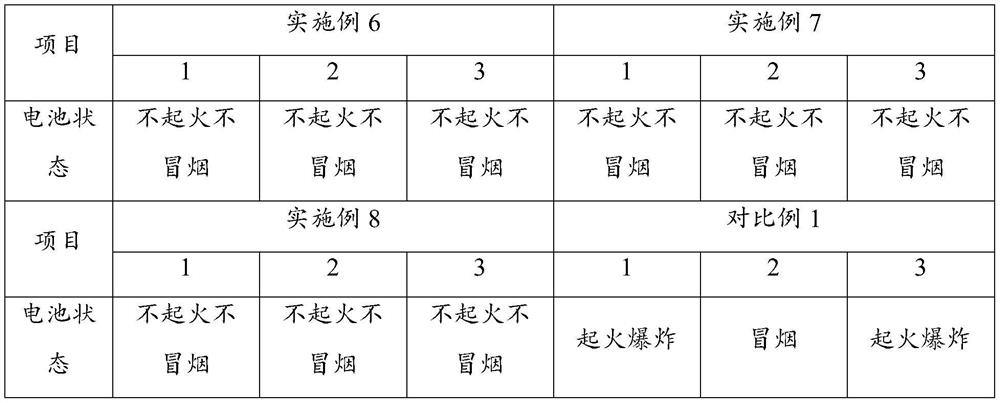

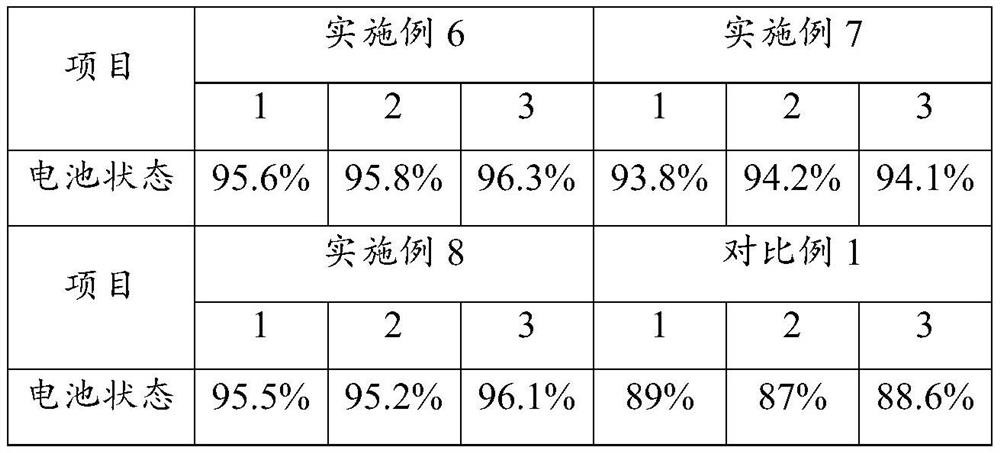

Microcapsule and preparation method thereof, electrolyte and preparation method thereof and battery

InactiveCN113036218AImprove high temperature safetyActive influenceFinal product manufactureFire rescueComposite materialElectrical battery

The invention provides a microcapsule and a preparation method thereof, an electrolyte and a preparation method thereof and a battery, and belongs to the technical field of batteries. The microcapsule comprises a capsule wall and a capsule core. The capsule wall is made of a first material. The capsule core is made of a second material, and the second material comprises silicon resin with flame retardance. The capsule wall covers the capsule core below a target temperature, the capsule wall is broken above the target temperature and releases the capsule core, and the first material is not dissolved in the electrolyte at least below the target temperature. The microcapsule is dispersed in the electrolyte of the battery, so that the electrical property of the battery is basically not influenced. When the temperature of the battery is higher than the target temperature, the capsule wall of the microcapsule is softened and broken, the microcapsule can release the capsule core of the microcapsule, and the silicon resin with flame retardance forms a diffusion shielding layer to prevent vaporized organic matters generated by high-temperature thermal decomposition of an internal high polymer material from diffusing to a combustion area. Meanwhile, the silicon resin has a very good heat insulation effect, heat transfer in the combustion process can be blocked to prevent continuous reaction, and then the high-temperature safety performance of the battery is improved.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

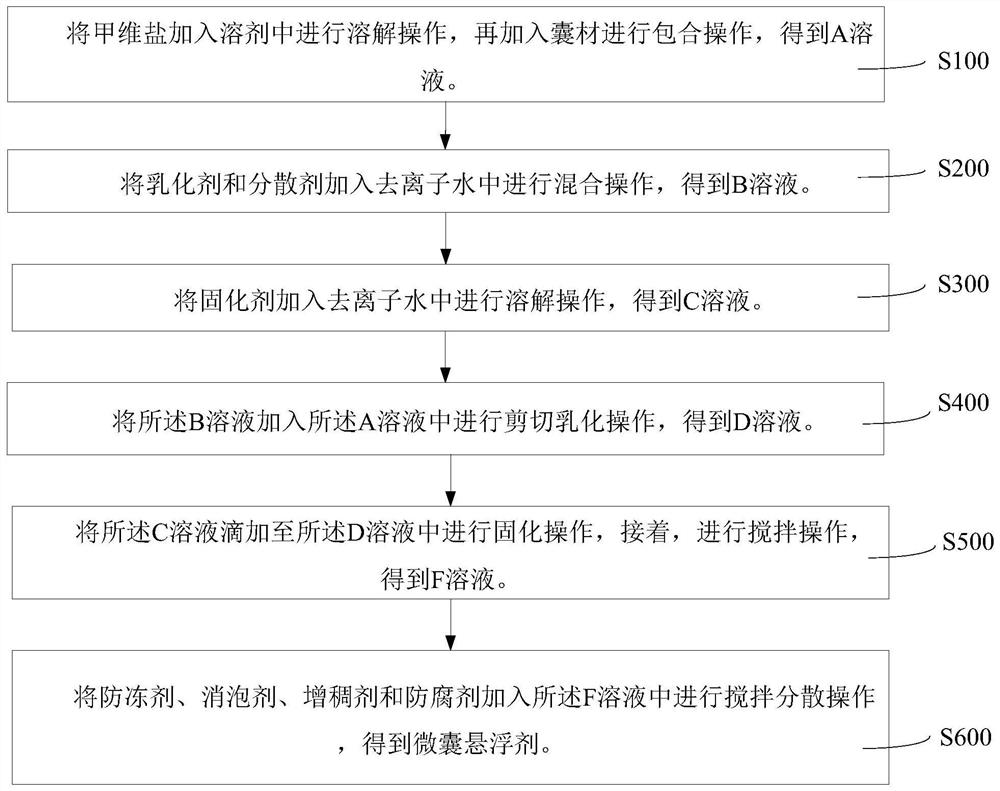

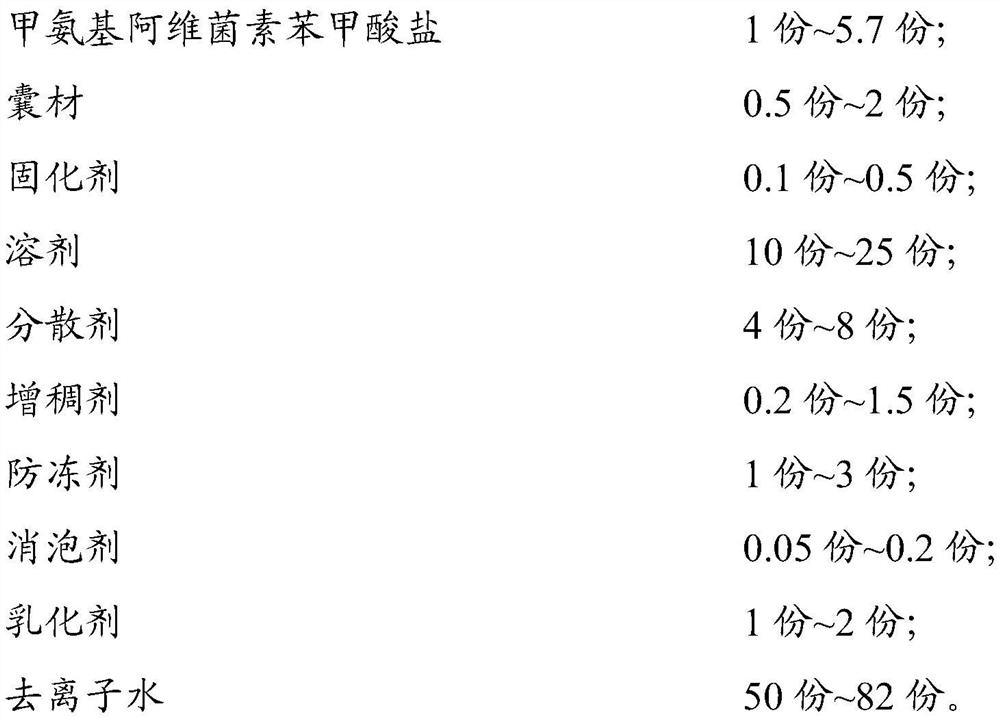

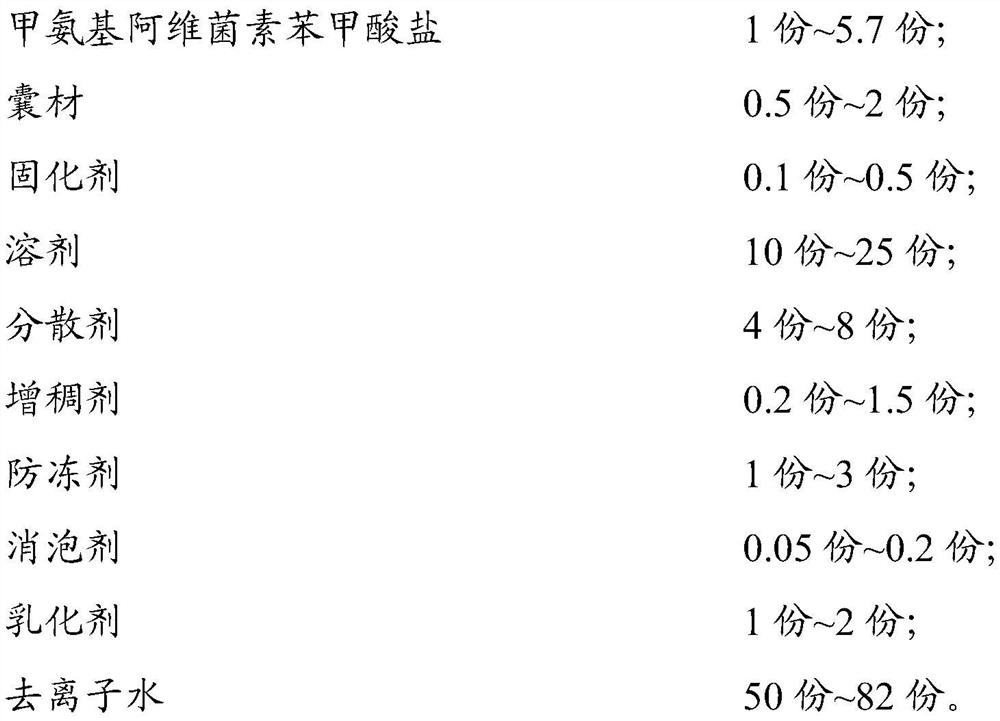

Emamectin benzoate microcapsule suspending agent and preparation method thereof

ActiveCN112155011AReduce dispersionHigh encapsulation efficiencyBiocideArthropodicidesMedicineFirming agent

The invention provides an emamectin benzoate microcapsule suspending agent and a preparation method thereof. The microcapsule suspending agent is prepared from the following components in parts by mass: 1 to 5.7 parts of emamectin benzoate; 0.5 to 2 parts of a capsule material; 0.1 to 0.5 part of a curing agent; 10 to 25 parts of a solvent; 4-8 parts of a dispersant; 0.2 to 1.5 parts of a thickening agent; 1-3 parts of an antifreezing agent; 0.05 to 0.2 part of a defoaming agent; 1-2 parts of an emulsifier; and 50 to 82 parts of deionized water. The microcapsule suspending agent is high in encapsulation efficiency and large in drug loading capacity.

Owner:HUIZHOU YINNONG TECH

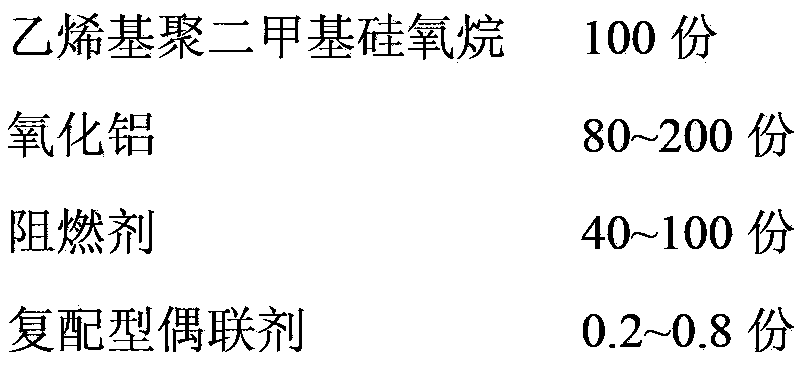

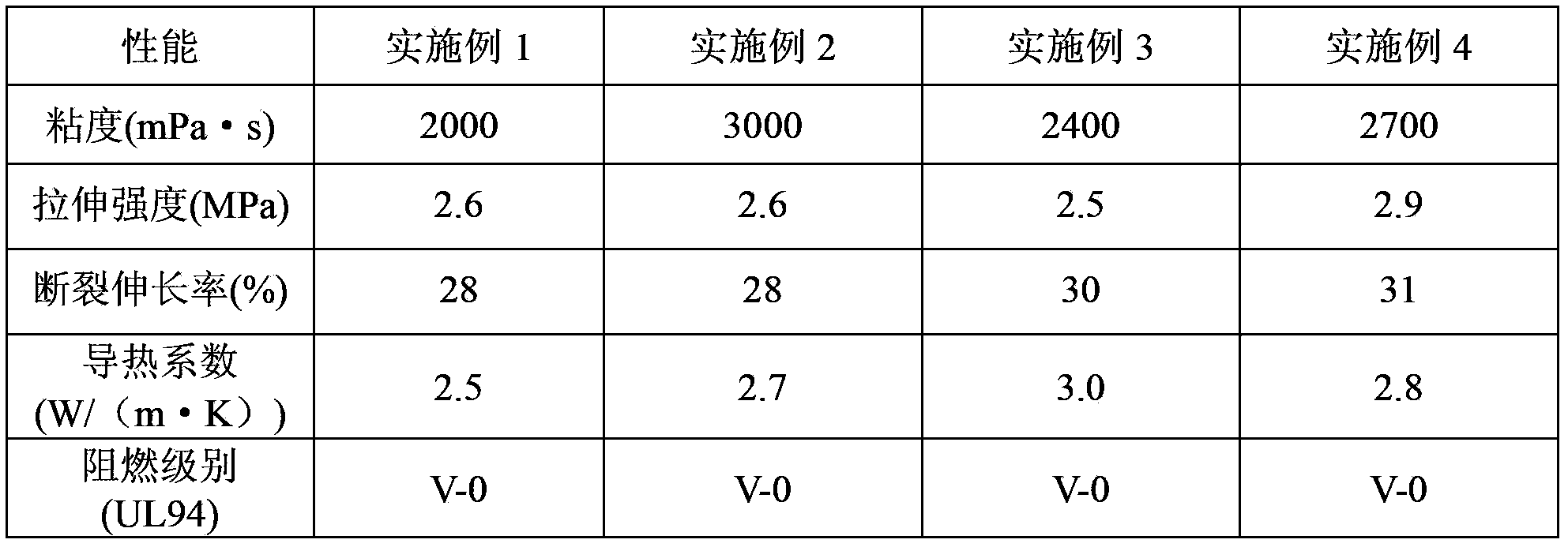

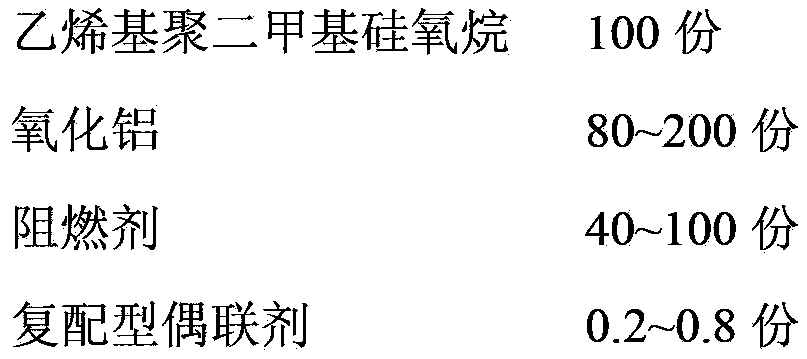

Low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and preparation method thereof

ActiveCN103146340BGood compatibilityLower surface energyNon-macromolecular adhesive additivesOther chemical processesSealantDimethyl siloxane

The invention provides low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and a preparation method thereof. The method comprises the following steps of: mixing high viscosity and low viscosity of vinyl polydimethylsiloxane; adding aluminum oxide with particle size of 1-5 microns as heat conduction filler; further adding a compound coupling agent formed by combining aluminic acid ester, KH570 (gamma-methylacryloyloxypropyl trimethoxysilane) and KH550 (gamma-aminopropyl triethoxysilane) and a compound flame retardant formed by combining melamine cyanurate and aluminum hydroxide into a base material system; and preparing the electronic pouring sealant according to a proper proportion. The prepared pouring sealant has high heat conductivity up to 2.5-3.0W.m<-1>.K<-1>, low viscosity of 2000-3000mPa.s, perfect fluidity and good flame retardance effect; and the production cost is low.

Owner:GUANGZHOU GLORYSTAR CHEM

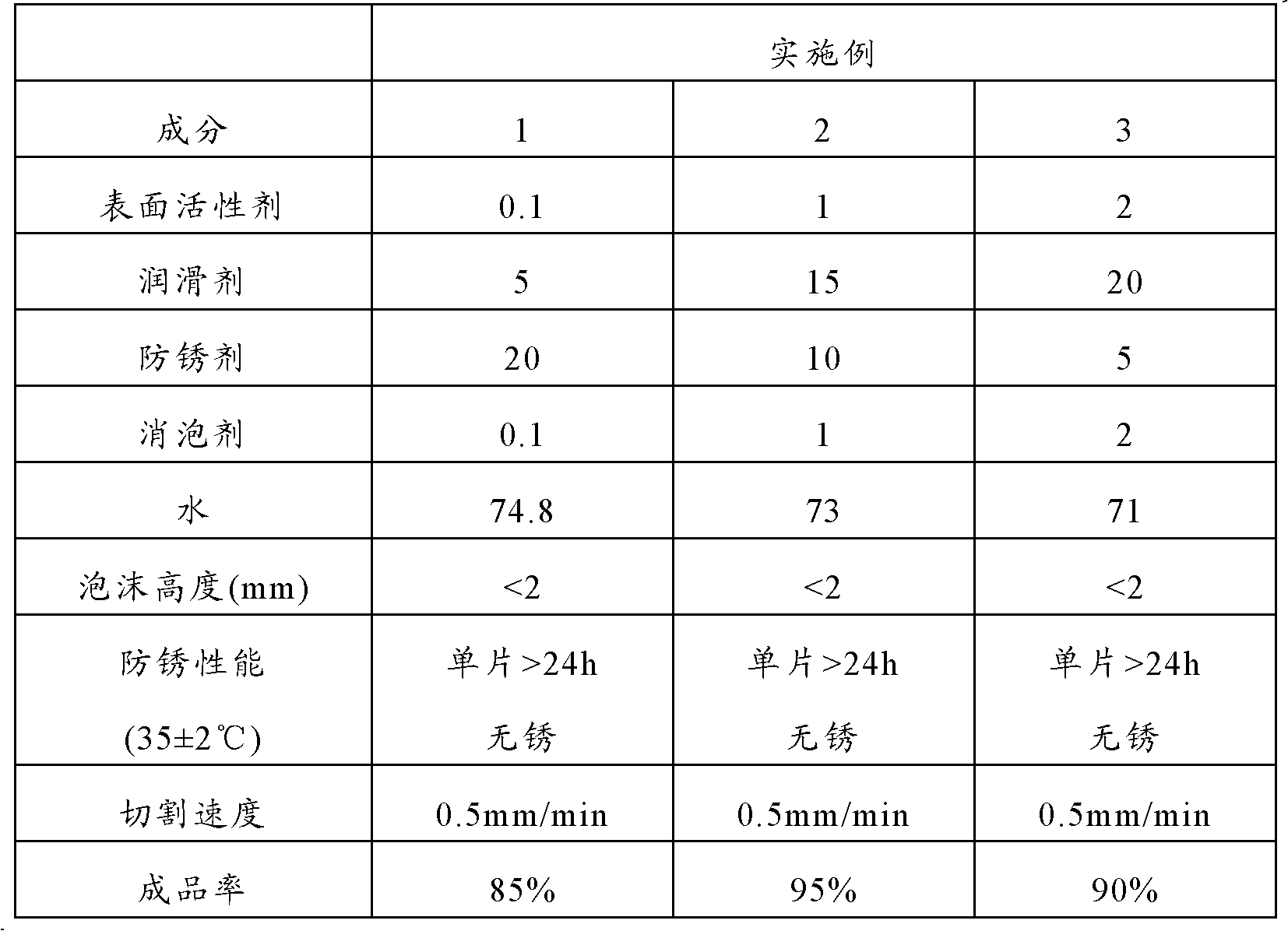

Water-soluble cooling liquid for fixed abrasive material line cutting, and preparation method thereof

ActiveCN103013638BDoes not increase viscosityImprove the lubrication effectLubricant compositionMaterials scienceCutting fluid

The present invention provides a water-soluble cutting liquid for fixed abrasive material line cutting, wherein the water-soluble cutting liquid is characterized by comprising, by weight, 0.1-10% of an non-ionic surfactant, 2-20% of an anti-rust sterilization agent, 4-20% of a lubricant, 0.1-2% of an antifoaming agent, and the balance of water. According to the present invention, the cutting liquid with performances of wetting, cleaning, cooling and rust resistance is achieved, is applicable for fixed abrasive material line cutting, and has characteristics of simple process and operation, no corrosion, no bubbling, no rust, no harm on human body, and low cost. The present invention further provides a preparation method for the water-soluble cooling liquid for fixed abrasive material line cutting.

Owner:ZHEJIANG SHUNLIAN INTELLIGENT EQUIP CO LTD

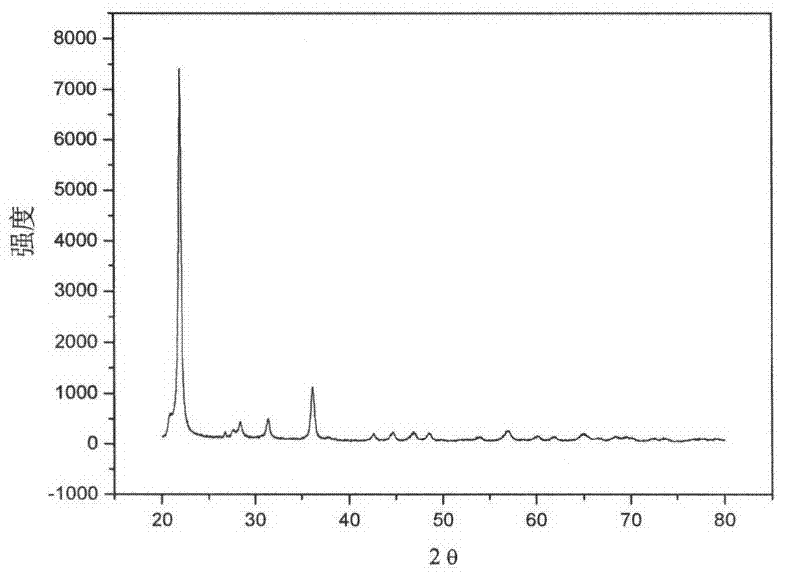

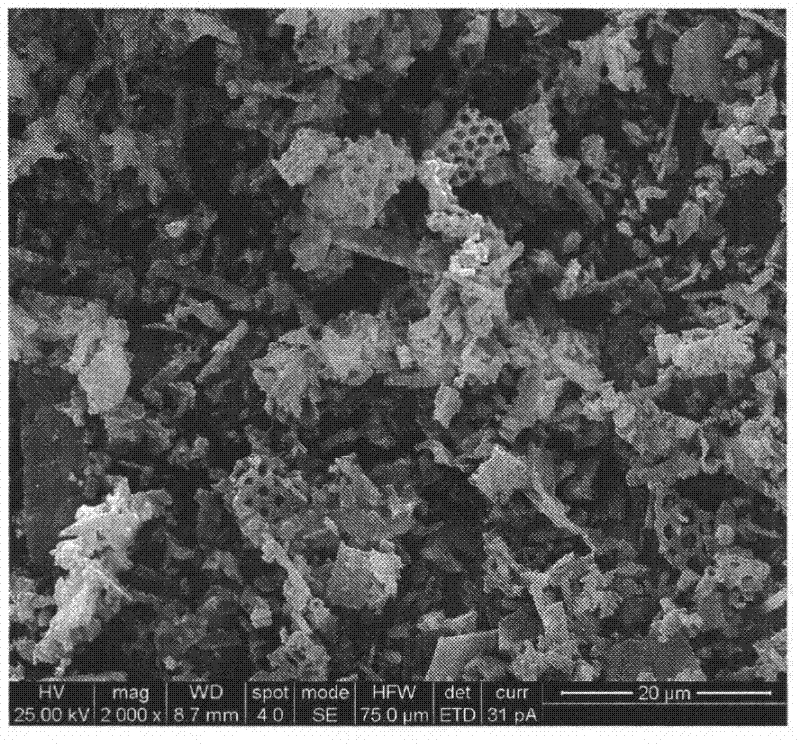

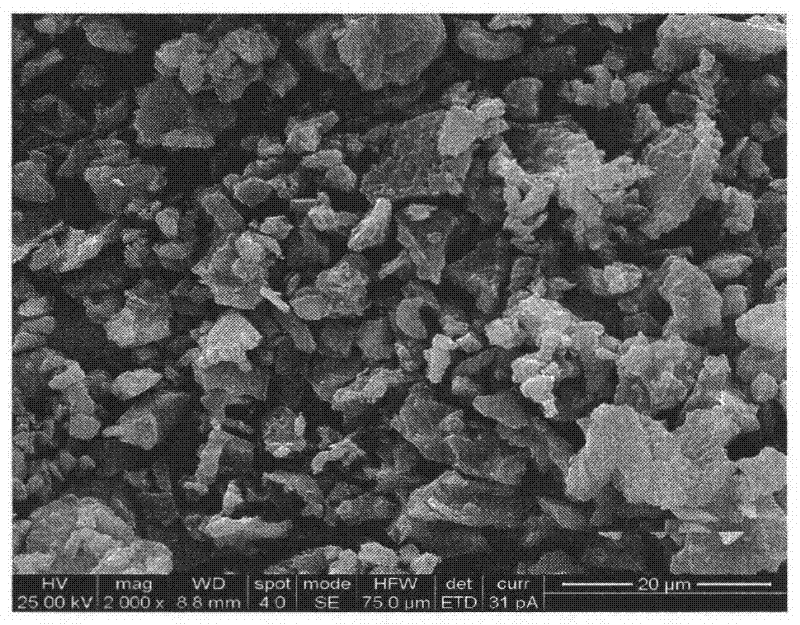

Preparation method of calcined diatomite flatting agent

ActiveCN101659796BImprove oil absorption capacityThickenCoatingsPigment treatment with macromolecular organic compoundsEmulsionSilicon dioxide

The invention relates to a preparation method of a calcined diatomite flatting agent, which is applicable to a water paint system of styrene-acrylate emulsion and pure acrylic emulsion and belongs to the field of paint additive. The method has the steps of taking the diatomite with the weight percentage content of silicon dioxide being more than 85 wt% as the raw material, adding NaCl accounting for 2-4wt% of the diatomite and starch accounting for 6-8wt% of the diatomite, calcining with the temperature of 850-950 DEG C and the time of 2-3h, crushing by using jet milling technology after calcining with the feed particle size being 0.1-1mm and the discharging particle size being 0-40 mum, and obtaining the end product by classification after crushing, wherein the particle sizes after classification are distributed as follows: 1-8 mum: 39-44 wt%; 8-25 mum: 38-42 wt%; and 25-35 mum: 18-20 wt%. The calcined diatomite flatting agent does not increase the paint consistency, and the glossiness of the coating are very approximate at the incident angles of 60 degrees and 85 degrees.

Owner:BEIJING UNIV OF TECH +1

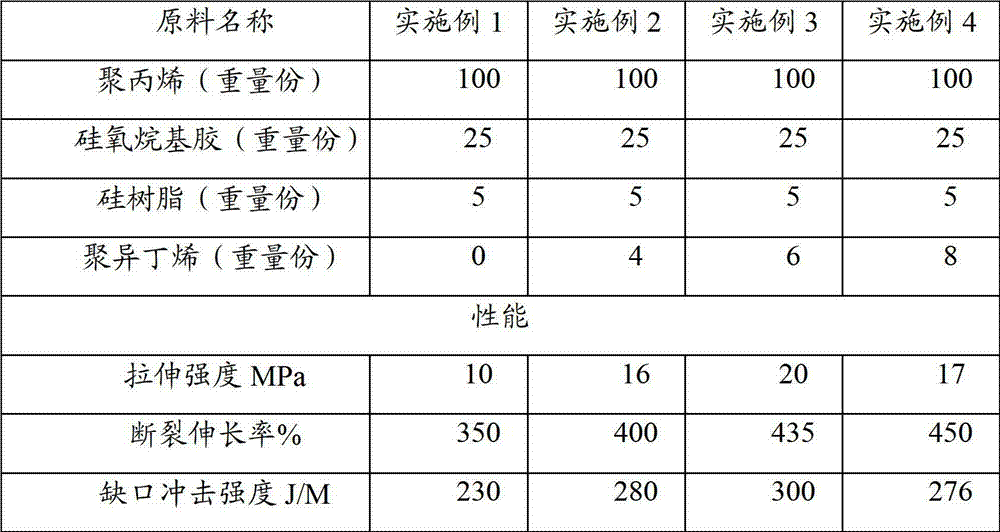

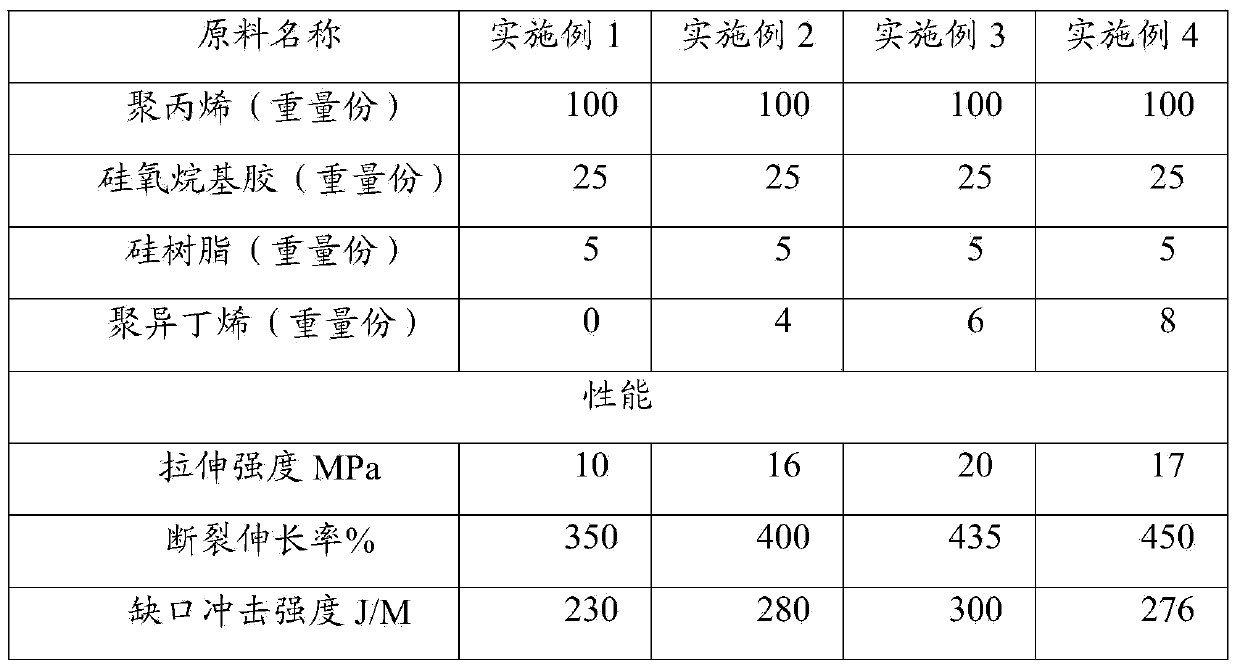

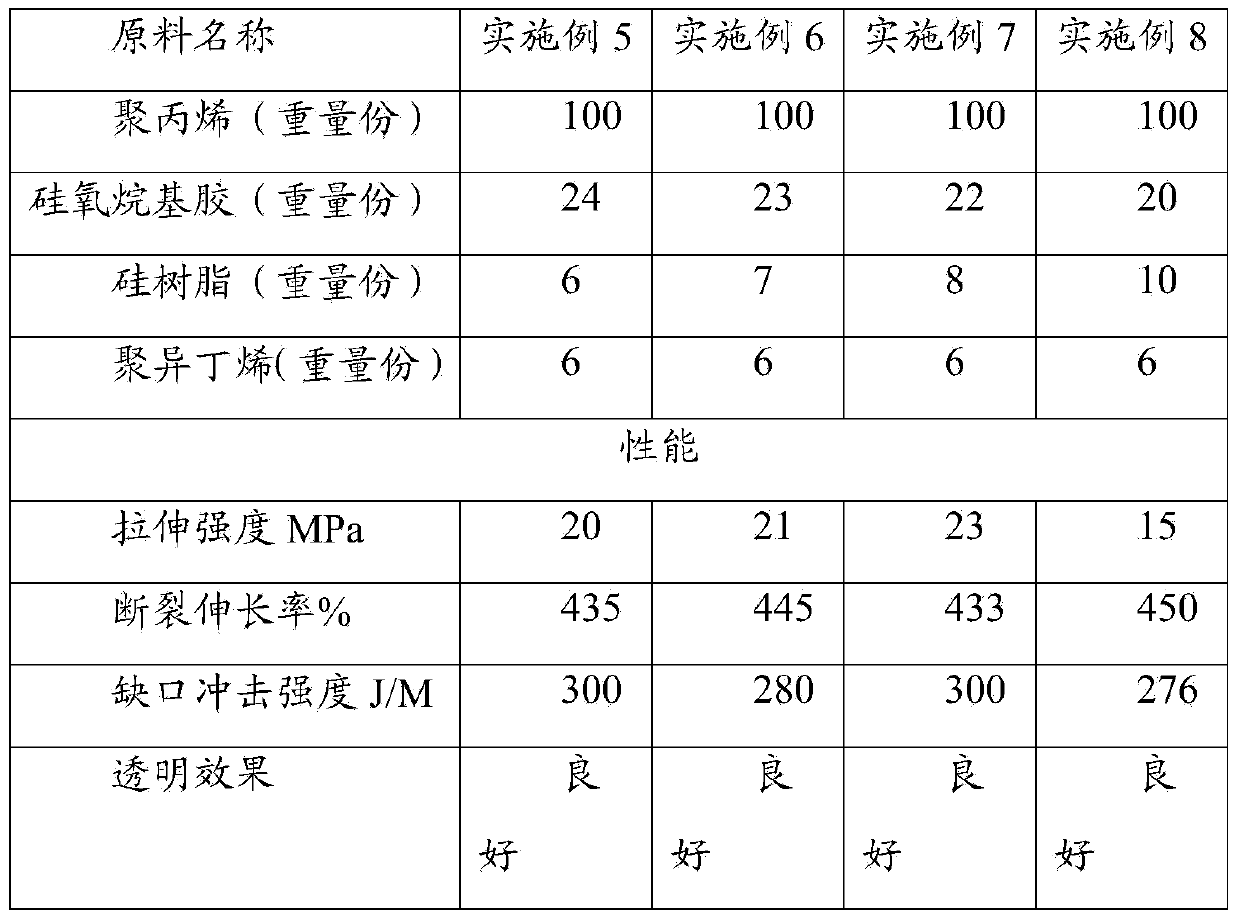

Siloxane-modified thermoplastic material and preparation method thereof

The invention relates to a method for preparing siloxane-modified thermoplastic material, which comprises the following steps: adding 100 weight parts of thermoplastic resin, 40-80 parts of high molecular weight siloxane, 20-40 parts of silicon resin, and 5-10 parts of compatibilizer into a blender, blending for 3-4min, then adding 10-25 weight parts of cross-linking agent and 0.01 -0.5 parts of hydrosilation catalyst, reacting and blending for 3-5min, discharging, cooling to the room temperature and obtaining a base stock; taking 100 weight parts of the base stock in the step one and 50-150 weight parts of thermoplastic resin for mixing uniformly, blending through an internal mixer or a double screw extruder and obtaining the siloxane-modified thermoplastic material. The cross-linking siloxane-modified thermoplastic material made by the invention has the advantages of higher heat resistance, excellent weather resistance, lower friction factor changing along with time, smooth surface, silk touch feeling and the like.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Method of silver-tarnishing prevention for silver-plated element of communication product

The invention provides a method of silver-tarnishing prevention for a silver-plated element of a communication product. The method comprises the following steps: pouring an electrical contact protection agent SP-2002S into a container; putting silver-plated elements into the protection agent for dip-coating, shaking the container so as to exhaust air, enabling the elements not to adhere to each other and carrying out dip-coating for 2 +- 1 min; carrying out brush coating, that is, taking some of the protection agent with a clean dry soft brush and uniformly brushing the protection agent on the surfaces of the elements, wherein, slits of the elements should be soaked; naturally drying the elements in the air or drying the elements with hot air at a temperature of no more than 120 DEG C. Particularly, 0.06 to 0.1 g / L of MOSS or PESS is added into the electrical contact protection agent SP-2002S.

Owner:NANJING PANDA HANDA TECH +2

Silicone mist suppressing agent

InactiveCN107641367AExcellent silicone mist suppression effectChange physical propertiesCoatingsThin material handlingPolymer scienceSolvent free

To provide a silicone mist suppressing agent capable of providing a composition and a cured product which are excellent in silicone mist suppressing effect and storage stability. The present inventionprovides the silicone mist suppressing agent comprising at least one kind of powder selected from an organic powder, an inorganic powder, and an inorganic / organic composite powder each having a volume-average particle diameter in the range of 100-4000 nm. The present invention also provides a solventless silicone composition which contains an organopolysiloxane having a viscosity in the range of25-50,000 mPa s at 25 DEG C and further contains the silicone mist suppressing agent in an amount of 0.1-10 pts.mass based on 100 pts.mass of the organopolysiloxane.

Owner:SHIN ETSU CHEM CO LTD

High-performance rigid polyurethane foam material containing epoxide group

InactiveCN101831045BImprove high temperature resistanceImprove mechanical propertiesEpoxyOrganometallic catalysis

The invention relates to a rigid polyurethane foam material, in particular to a high-performance rigid polyurethane foam material containing epoxide group, which is characterized by being prepared by the reaction of the following components: isocyanate with 28-32wt% of NCO, polyalcohol compound with the OH value of 300-800, epoxy resin with the epoxy equivalent weight more than 100, catalyst compound, foam stabilizer and water, wherein the isocyanate component at least contains polyaryl polymethylene isocyanate; the polyalcohol compound at least contains polyalcohol component taking tolylenediamine as initiator; and the catalyst compound at least contains imidazole derivative catalyst, tertiary amine catalyst and organo-metallic catalyst. The rigid polyurethane foam material has high strength and super toughness as well good size stability, maintains excellent mechanical performance at higher temperature, and can be applied to wood-imitation material, filling material, thermal insulation material and the like.

Owner:BEIJING UNIV OF CHEM TECH

Saturated salt filtrate reducer polymer for drilling fluid

InactiveCN105176500ANo pollution in the processImprove performanceDrilling compositionPolymer scienceSeawater

The invention discloses a saturated salt filtrate reducer polymer for drilling fluid. The saturated salt filtrate reducer polymer is prepared from the following components in percentage by weight: 80 percent of raw material A (polymer) and 20 percent of raw material B (modified starch). The saturated salt filtrate reducer polymer is prepared by reacting natural materials with active substances with special functions by a special process; the saturated salt filtrate reducer polymer is superior to artificially-synthesized polymer filtrate reducers in property, has better temperature tolerance and salt tolerance, and is suitable for drilling fluid systems containing fresh water, and saline water and seawater with various concentrations; the saturated salt filtrate reducer polymer does not ferment in the drilling fluid, can be biologically degraded and is free from pollution to the environment, so the saturated salt filtrate reducer polymer belongs to a green environment-friendly product.

Owner:ANHUI LUHAI PETROLEUM AUX TECH

A kind of dry transfer printing textile and preparation method thereof

ActiveCN103774469BIncrease contentDoes not increase viscosityDyeing processTextile printerCoated surface

Owner:KAISHENG TEXTILE

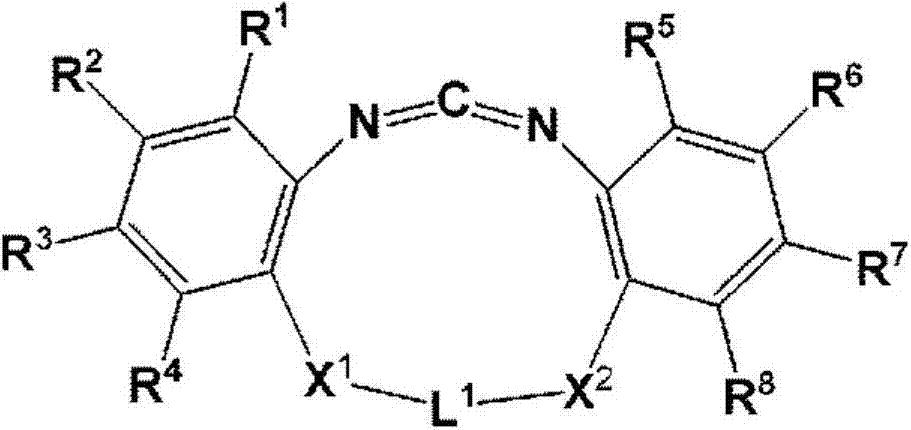

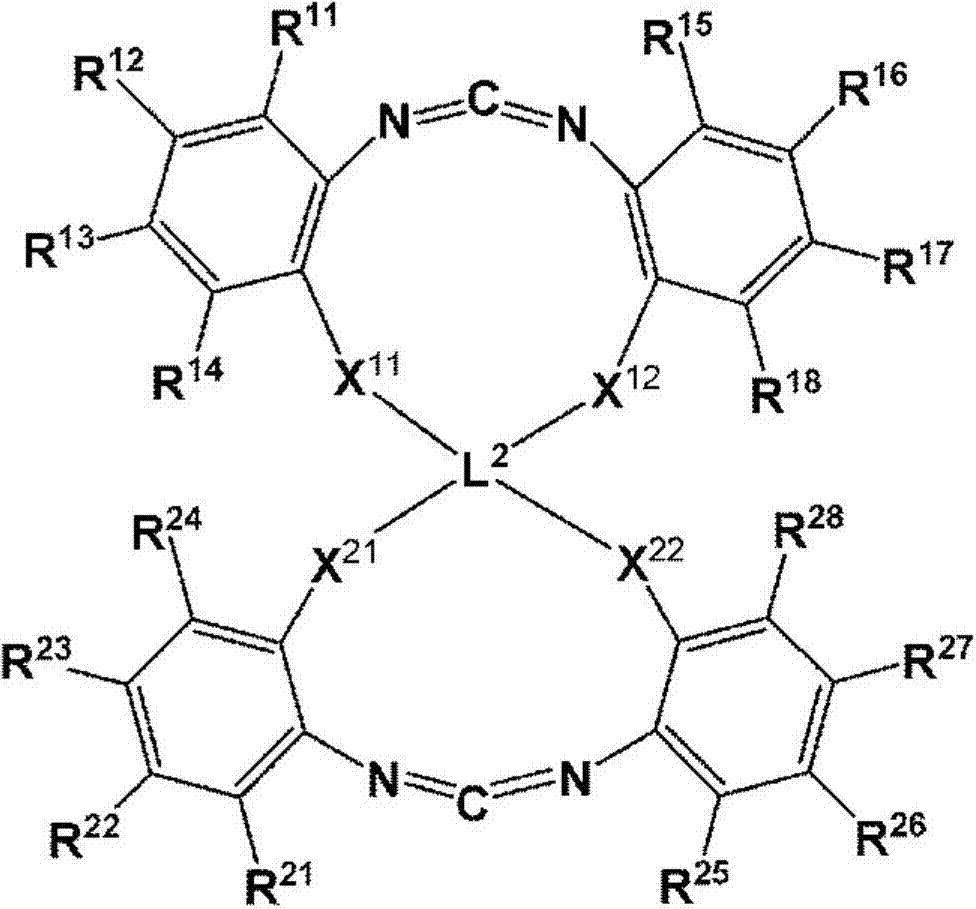

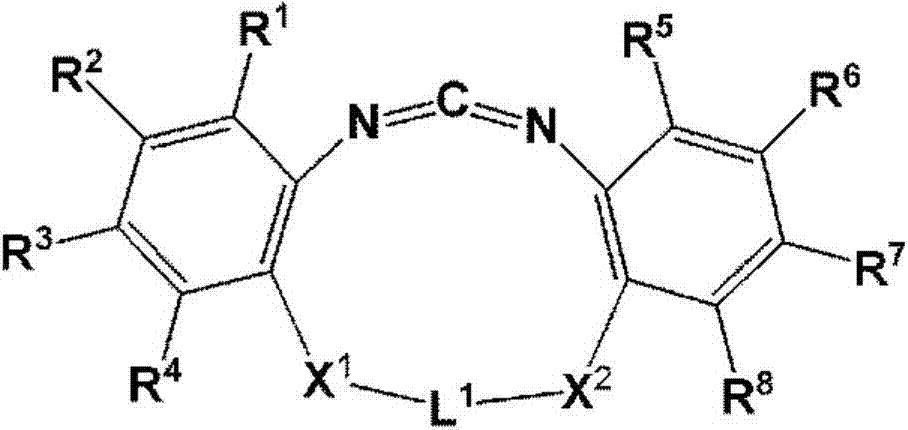

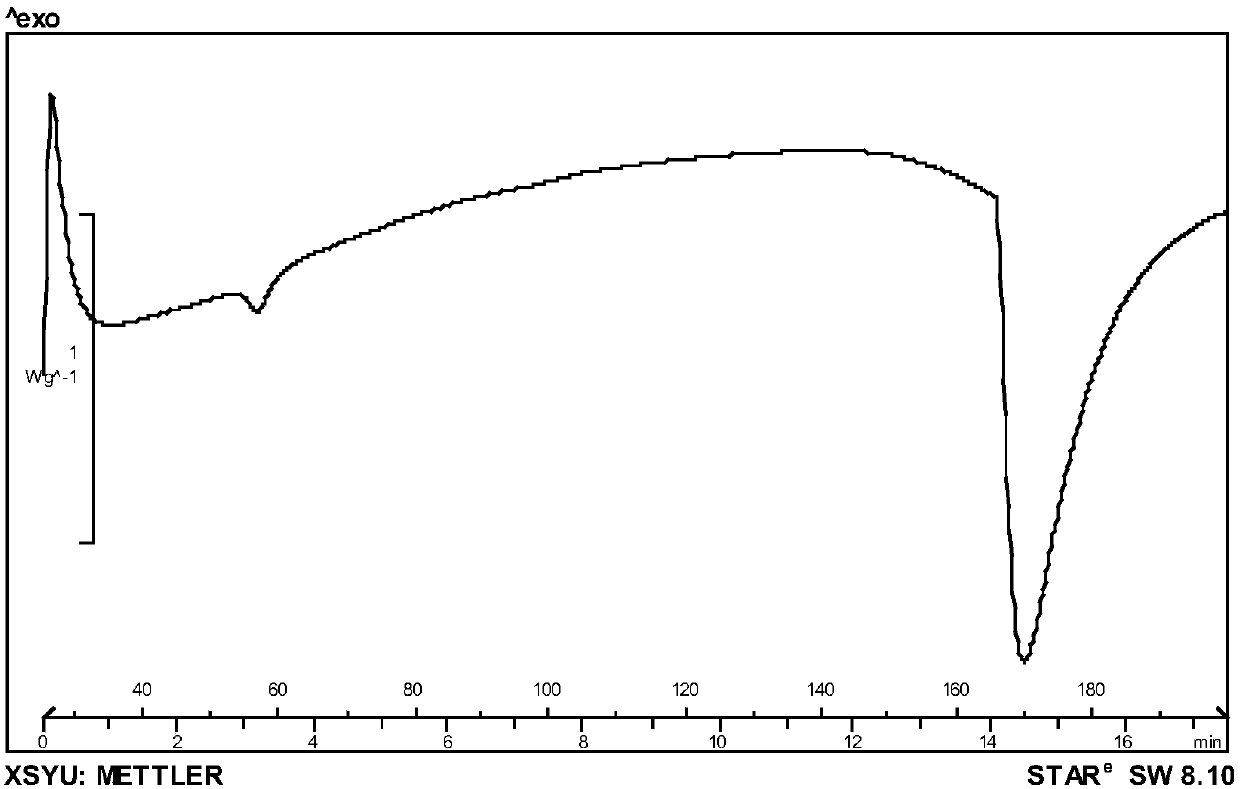

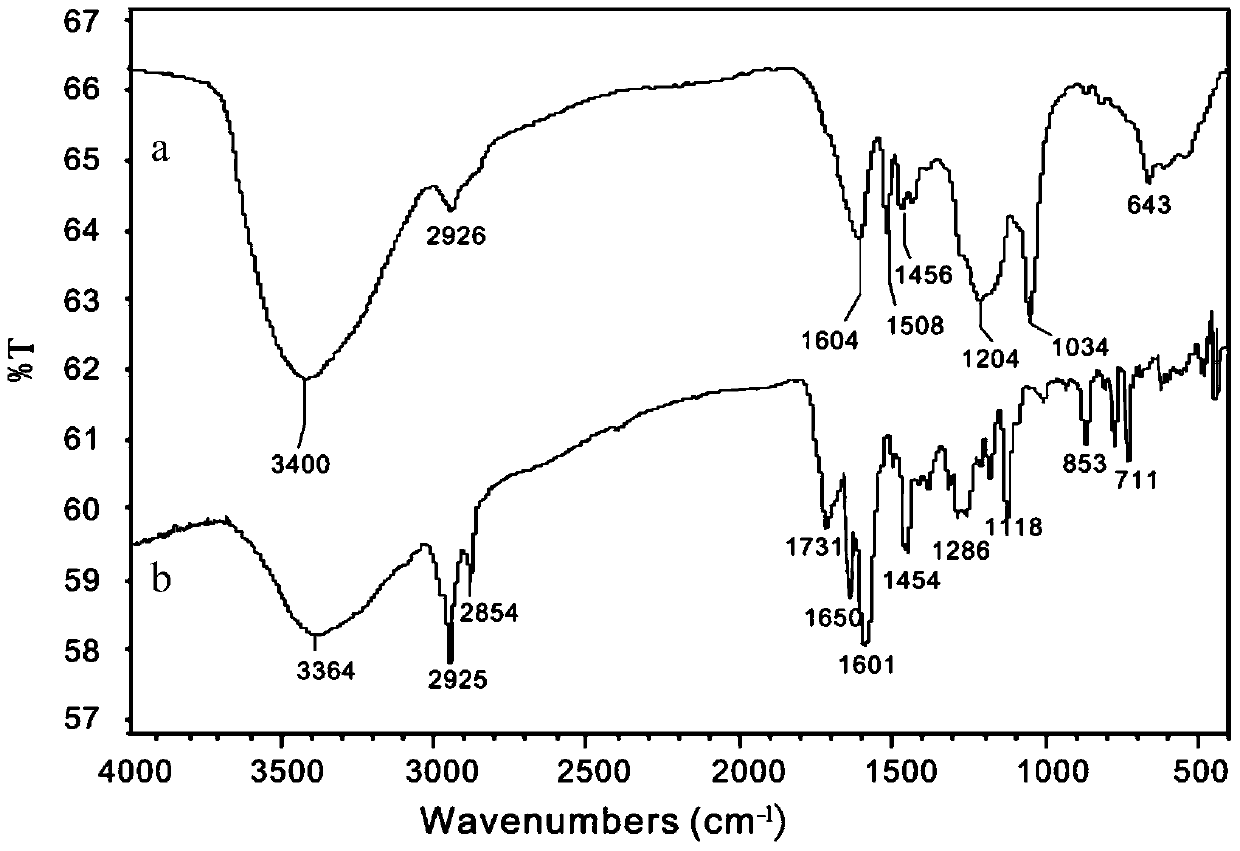

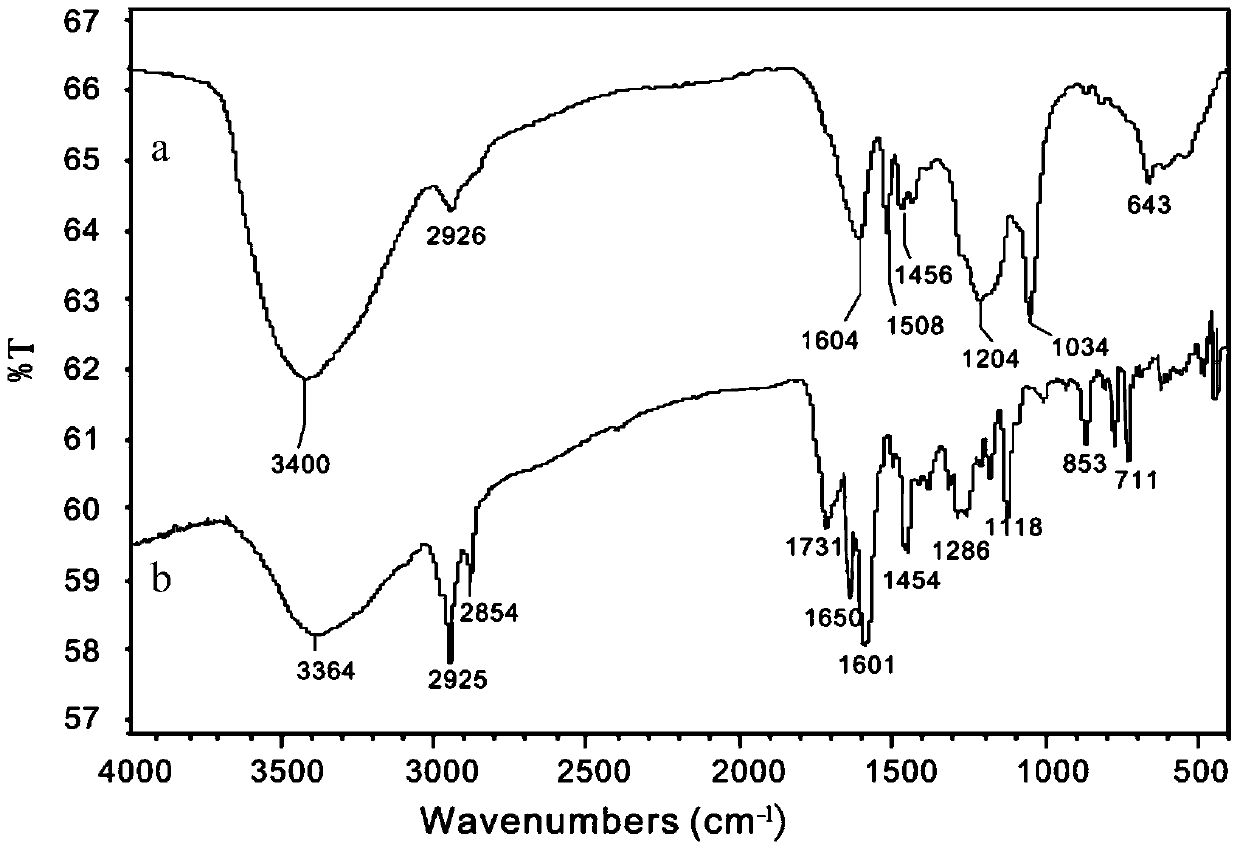

Cyclic carbodiimide compound, polyester film, back sheet for solar cell module and solar cell module

InactiveCN104302631ADoes not increase viscosityImprove film thickness uniformityOrganic chemistryDomestic articlesPolyesterAryl

A cyclic carbodiimide compound represented by formulas (O-1) or (O-2) can be used for producing a polyester film that does not contain isocyanates with a small molecular weight and that has excellent thickness uniformity without any thickening, and is capable of suppressing thickening when producing a film and suppressing generation of isocyanate gas. (R1, R5, R11, R15, R21 and R25 are an alkyl group, an aryl group or an alkoxy group; R2-R4, R6-R8, R12-R14, R16-R18, R22-R24 and R26-R28 are a hydrogen atom, an alkyl group, an aryl group or an alkoxy group; R1-R8 can be linked together to form a cycle; R11-R28 can be linked together to form a cycle; X1, X2, X11, X12, X21 and X22 are a single bond, and -O-, -CO-, -S-, -SO2-, -NH- or -CH2-; L1 is a divalent linking group; and L2 is a tetravalent linking group.)

Owner:FUJIFILM CORP

A kind of multifunctional additive for oil-based drilling fluid and preparation method thereof

InactiveCN104194742BGood oil solubilityImprove filtration loss reduction effectDrilling compositionSolubilityFiltration

The invention relates to a multifunctional additive for an oil-based drilling fluid and a preparation method of the multifunctional additive. Xylene is adopted as a reaction solvent, concentrated sulfuric acid is adopted as a catalyst, cocoyl diethanolamine is grafted onto humic acid by virtue of esterification reaction and thus the chemical modification of humic acid is achieved, as a result, humic acid molecules have good oil solubility, the modified humic acid molecules contain a large number of acylamino groups RCONR2, ester groups -COOR, -OH, -COOH, -C=O and -O- and other groups, N and O atoms in the groups can form hydrogen bonds with H atoms on other polar groups, interactions occur between the molecules by virtue of the hydrogen bonds and electrostatic attraction and thus a network structure with a large specific surface area is formed and a three-dimensional network structure is formed between the long alkyl straight chains in the molecules by virtue of an association effect. The multifunctional additive product has the advantages of filtration reducing property, increased shearing force, high-temperature resistance, calcium ion resistance and no viscosity increasing and the rheological property of the slurry can be maintained at a good state.

Owner:XI'AN PETROLEUM UNIVERSITY

Water-based ink composition for writing instruments

ActiveCN107129720BImprove write performanceDeterioration of dispersion stabilityInksBall-point pensPolymer scienceOrganic chemistry

The present invention provides a water-based ink composition for writing instruments, which includes at least 5 mass % or more of resin particles with a volume basis median diameter D50 of 0.3 μm or more and 0.05 to 10 mass % of butylene glycol·ethylene. Alcohol copolymer, wherein the aqueous ink composition is excellent in drying resistance without reducing the dispersion stability of the resin particles, and the aqueous ink composition is suitable for writing instruments such as water-based ink ballpoint pens and markers.

Owner:MITSUBISHI PENCIL CO LTD

Adhesive layer based on epoxy adhesive

ActiveCN110484158AImprove toughnessHigh strengthNon-macromolecular adhesive additivesFilm/foil adhesivesGraphene nanoplateletEpoxy adhesive

The invention provides an adhesive layer based on an epoxy adhesive, which can solve the problems that the engineering technical requirements are difficult to meet by adopting the existing epoxy adhesive as the adhesive layer, and the cost is higher when the adhesive layer is prepared by completely using the modified epoxy adhesive. The adhesive layer is formed by curing an unmodified epoxy adhesive, a modified epoxy adhesive and an unmodified epoxy adhesive which are sequentially arranged in the length direction of the adhesive layer, the modified epoxy adhesive is prepared from the unmodified epoxy adhesive and the graphene nanosheets in proportion, and the graphene nanosheets are uniformly dispersed in the unmodified epoxy adhesive.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com