Active polymer dye ink and applications of active polymer dye ink in ink jet printing and dyeing process for cotton fabrics

A technology of polymer dyes and reactive dyes, which is applied in the field of inkjet printing and dyeing technology, can solve the problems of low washing fastness and poor brightness of ink, and achieve the effects of good color fixing effect, high appearance and transparent appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of reactive polymer dye ink is applied to the ink-jet printing printing and dyeing process on the cotton fabric, comprises the following steps,

[0037] 1) Cotton fabric reactive dye printing pretreatment:

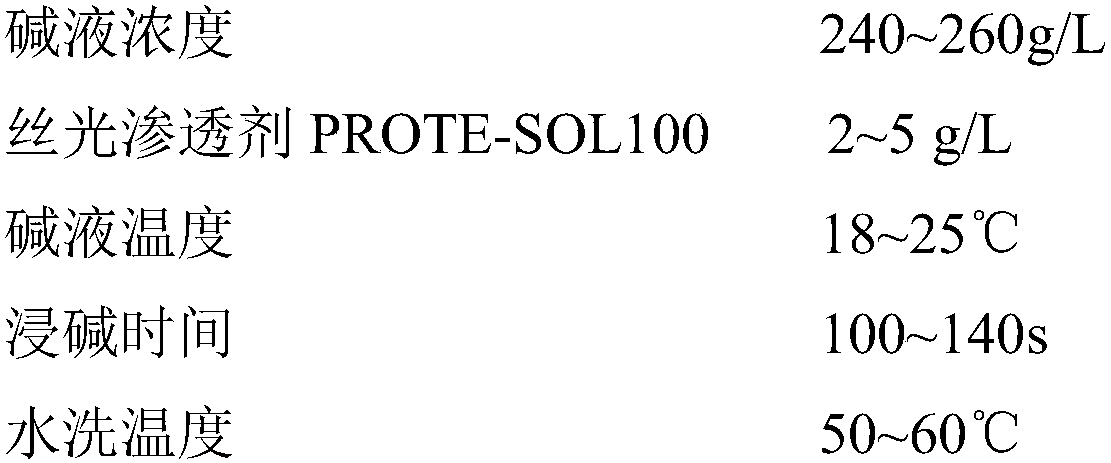

[0038] Singeing, mercerizing, open-width continuous bleaching, biological enzyme polishing, and three mercerizing treatments are performed on the knitted gray fabric in order to obtain cotton knitwear; singeing can remove the fluff on the surface of the cotton yarn, and make the surface of the cotton knitted fabric smooth and clean. Smooth, clear texture, mercerized treatment provides a high level of gray fabric for reactive dye printing, the process conditions of mercerized treatment:

[0039]

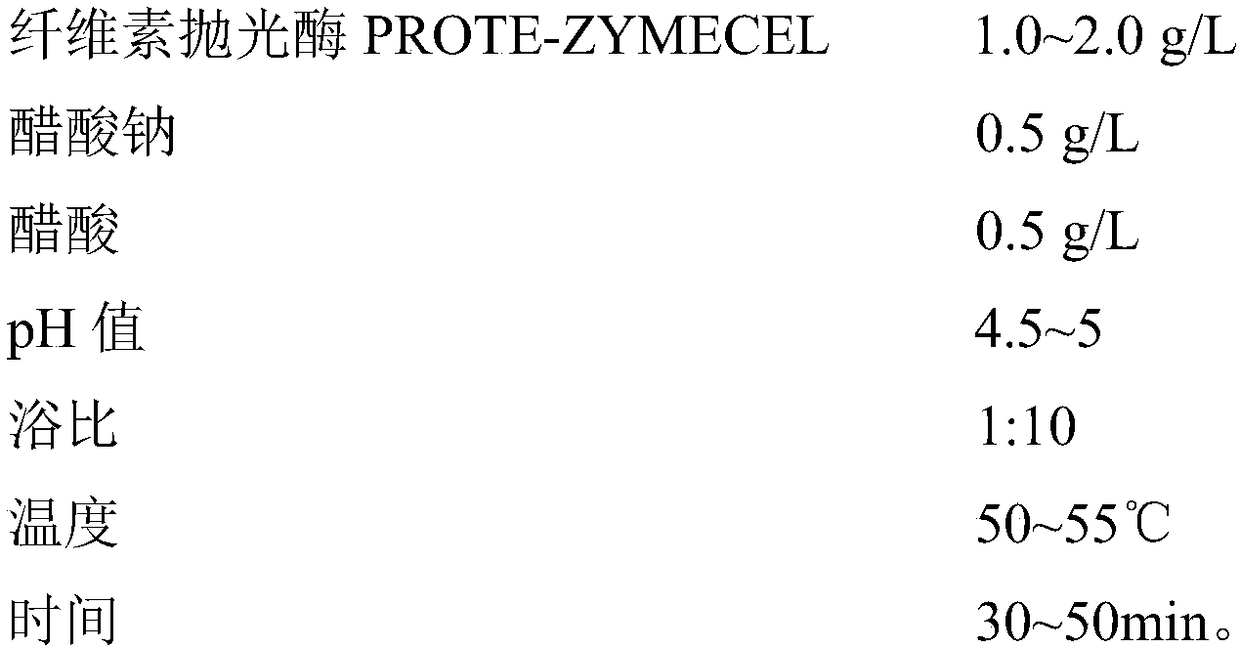

[0040] Process conditions of biological enzyme polishing:

[0041]

[0042] Bioenzyme polishing is to use biological enzymes to remove surface substances of gray cloth, so that the gray cloth is anti-pilling, soft and fluffy, and the effect of bio-polishing fi...

Embodiment 2

[0052] A kind of reactive polymer dye ink is applied to the ink-jet printing printing and dyeing process on the cotton fabric, comprises the following steps,

[0053] 1) Cotton fabric reactive dye printing pretreatment:

[0054] Singeing, mercerizing, open-width continuous bleaching, biological enzyme polishing, and three mercerizing treatments are performed on the knitted gray fabric in order to obtain cotton knitwear; singeing can remove the fluff on the surface of the cotton yarn, and make the surface of the cotton knitted fabric smooth and clean. Smooth, clear texture, mercerized treatment provides a high level of gray fabric for reactive dye printing, the process conditions of mercerized treatment:

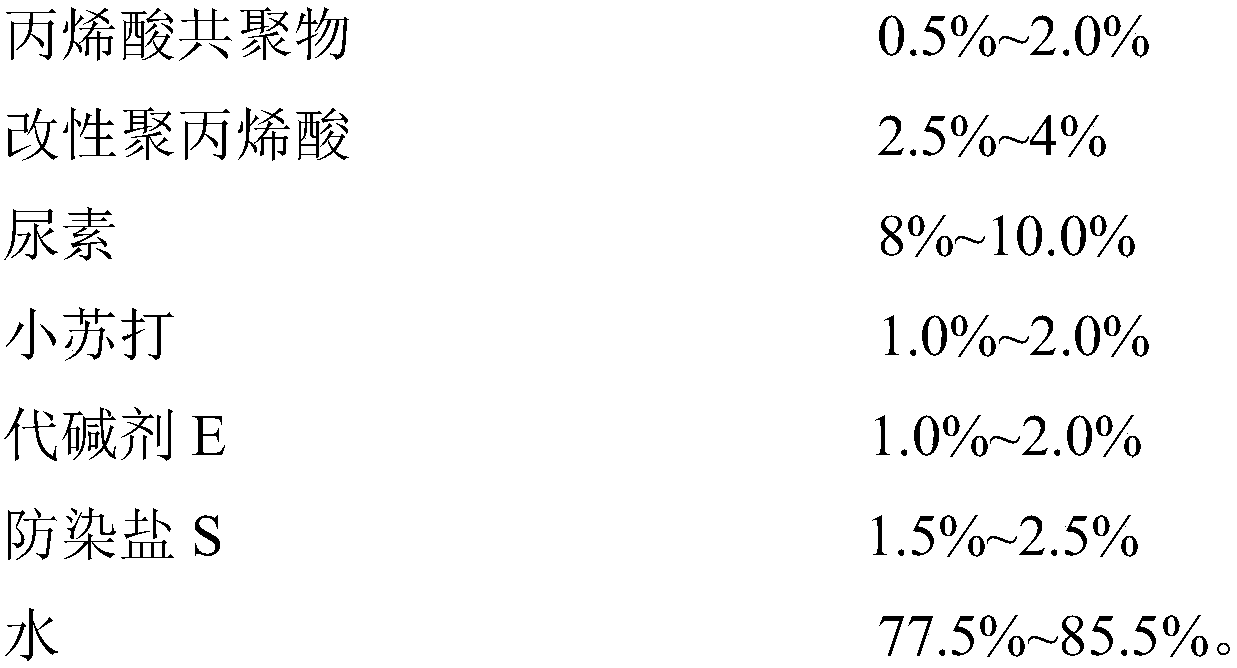

[0055]

[0056]

[0057] Process conditions of biological enzyme polishing:

[0058]

[0059] Bioenzyme polishing is to use biological enzymes to remove surface substances of gray cloth, so that the gray cloth is anti-pilling, soft and fluffy, and the effect of bio-po...

Embodiment 3

[0068] A kind of reactive polymer dye ink is applied to the ink-jet printing printing and dyeing process on the cotton fabric, comprises the following steps,

[0069] 1) Cotton fabric reactive dye printing pretreatment:

[0070] Singeing, mercerizing, open-width continuous bleaching, biological enzyme polishing, and three mercerizing treatments are performed on the knitted gray fabric in order to obtain cotton knitwear; singeing can remove the fluff on the surface of the cotton yarn, and make the surface of the cotton knitted fabric smooth and clean. Smooth, clear texture, mercerized treatment provides a high level of gray fabric for reactive dye printing, the process conditions of mercerized treatment:

[0071]

[0072] Process conditions of biological enzyme polishing:

[0073]

[0074]

[0075] Bioenzyme polishing is to use biological enzymes to remove surface substances of gray cloth, so that the gray cloth is anti-pilling, soft and fluffy, and the effect of bio-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com