Adhesive layer based on epoxy adhesive

A technology of epoxy adhesive and bonding layer, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problem of not being able to guarantee the curing of the adhesive at the same time, affecting the performance of the bonding layer, etc., and achieve good shear force damage. , excellent mechanical properties, the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

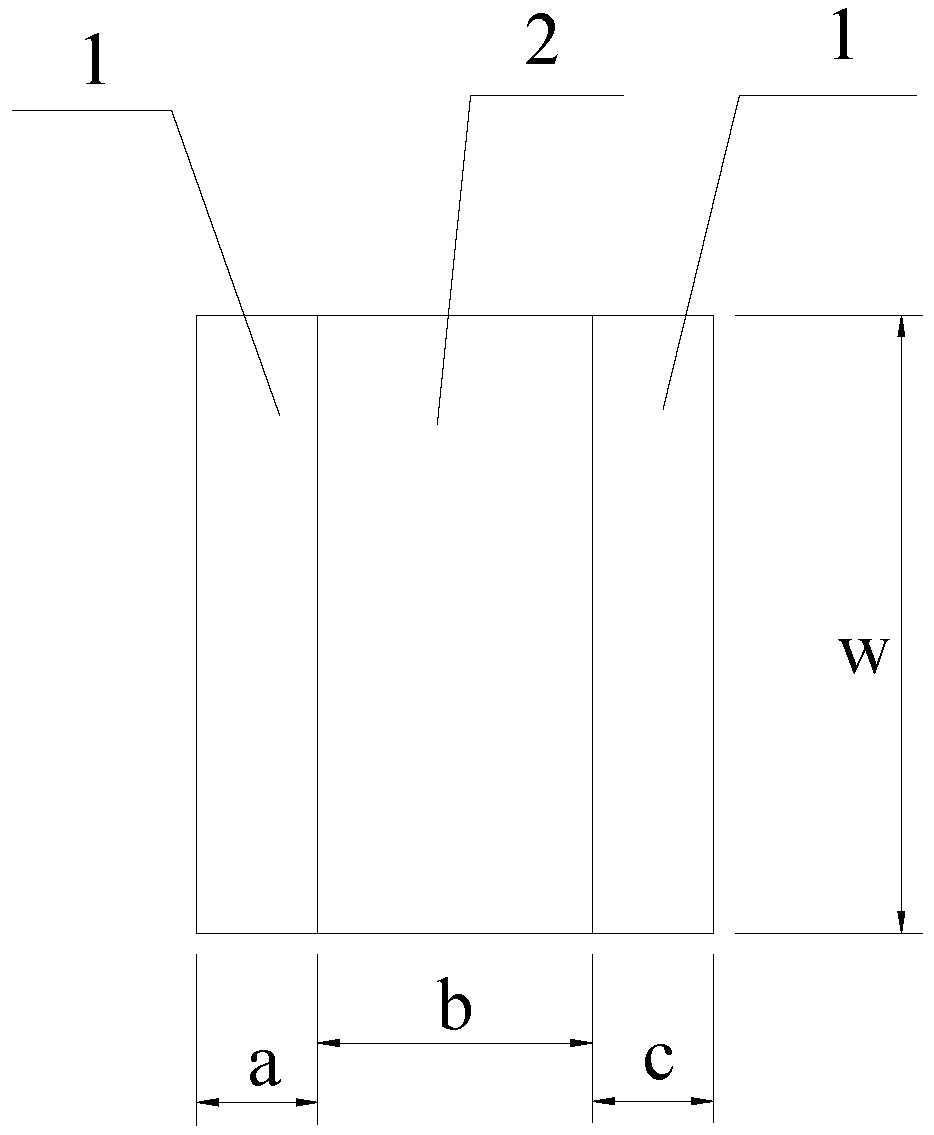

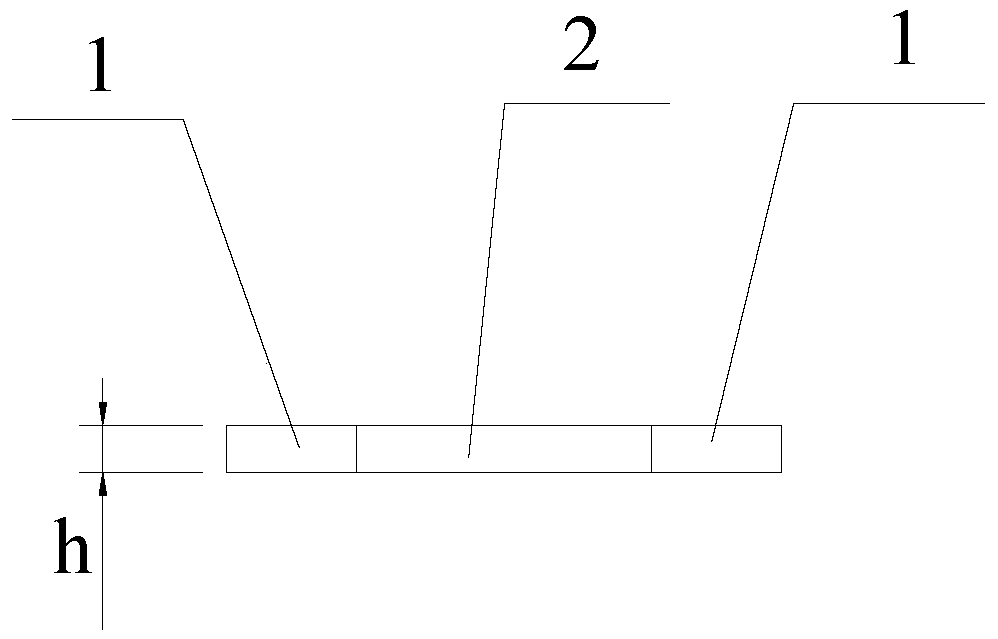

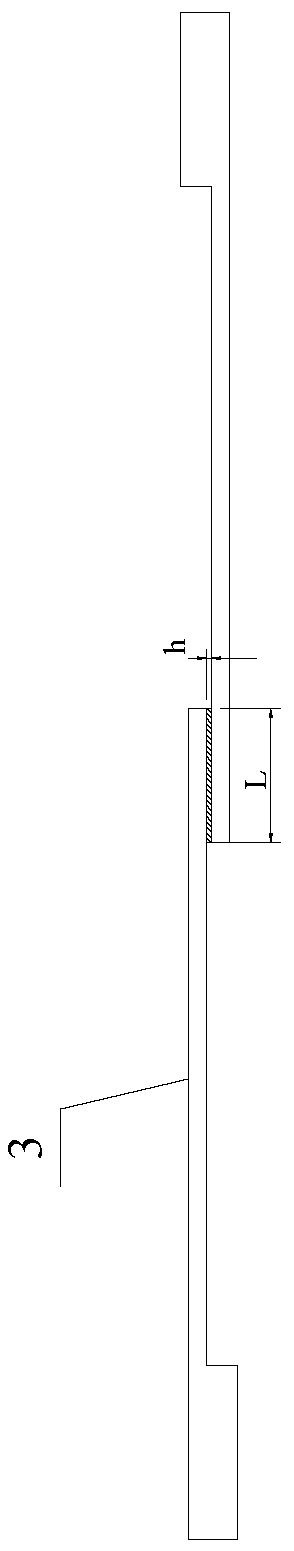

[0028] See figure 1 and figure 2 , a bonding layer based on epoxy adhesive of the present invention, which is solidified by unmodified epoxy adhesive 1, modified epoxy adhesive 2 and unmodified epoxy adhesive 1 arranged in sequence along the length direction of the bonding layer Formed; the length ratio of unmodified epoxy adhesive 1, modified epoxy adhesive 2 and unmodified epoxy adhesive 1 is a:b:c=1:(1~3):1, within this ratio range Functionally gradient adhesive layer with good mechanical properties, the width w and thickness h of unmodified epoxy adhesive 1, modified epoxy adhesive 2 and unmodified epoxy adhesive 1 are all equal; modified epoxy adhesive 2 is composed of unmodified epoxy adhesive Graphene nanosheets are uniformly dispersed in the unmodified epoxy adhesive; unmodified epoxy adhesive 1 is prepared by epoxy resin and curing agent in proportion ; In the modified epoxy adhesive, the quality of the graphene nanosheets accounts for 0.25% to 0.75% of the mass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com