Water-soluble cooling liquid for fixed abrasive material line cutting, and preparation method thereof

A water-soluble, wire-cutting technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of reducing the service life of wire-cutting machinery, reducing the cutting accuracy of equipment, and rusting of wire-cutting machinery, so as to achieve good lubrication performance and reduce rust probability, and the effect of improving the antirust ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a water-soluble cutting fluid for fixed abrasive wire cutting, comprising:

[0041] Mixing the antirust agent with water to obtain a first solution;

[0042] Mixing the nonionic surfactant with water to obtain an aqueous surfactant solution;

[0043] Adding an antifoaming agent and a lubricant to the aqueous surfactant solution in turn to obtain a second solution;

[0044] mixing the first solution with the second solution to obtain a water-soluble cutting fluid for fixed abrasive wire cutting;

[0045] Among them, the raw materials include: 0.1% to 10% of non-ionic surfactant; 2% to 20% of antirust agent; 4% to 20% of lubricant; 0.1% to 2% of defoamer according to the weight percentage of the total amount of cutting fluid; The balance is water; the antirust agent is one or more of organic alcohol amine compounds, nitrite or benzotriazole and its derivatives.

[0046] According to the present invention, the r...

Embodiment 1

[0055] 1. Weigh and mix 20 parts by weight of triethanolamine and water, and stir evenly to make a uniform and transparent solution.

[0056] 2. Weigh 0.1 parts by weight of nonylphenol polyoxyethylene ether, 0.1 parts by weight of silicone oil, 5 parts by weight of polyethylene glycol and water, and mix and stir evenly to obtain a surfactant solution.

[0057] Mix the transparent solution prepared in 1 and 2 with the surfactant solution, and stir evenly to obtain a water-soluble cutting fluid for fixed abrasive wire cutting.

Embodiment 2

[0060] 1. Weigh and mix 10 parts by weight of triethanolamine and water, and stir evenly to make a uniform and transparent solution.

[0061] 2. Weigh 1 part by weight of nonylphenol polyoxyethylene ether, 1 part by weight of silicone oil, 15 parts by weight of polyethylene glycol and water, and mix and stir evenly to obtain a surfactant solution.

[0062] Mix the transparent solution prepared in 1 and 2 with the surfactant solution, and stir evenly to obtain a water-soluble cutting fluid for fixed abrasive wire cutting.

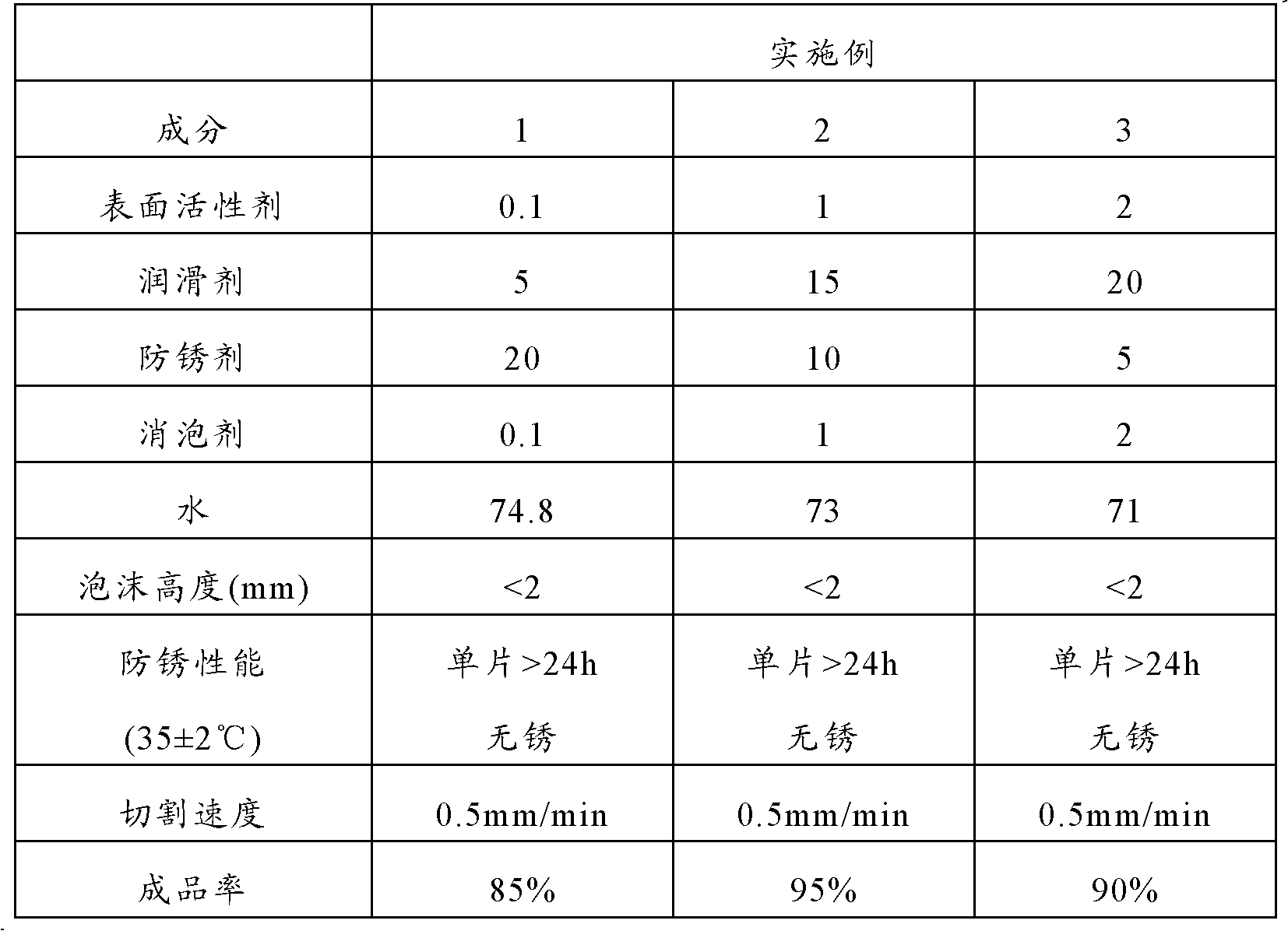

[0063] Through the cutting fluid workshop experiment, the results show that the cutting fluid can meet the cutting requirements of the fixed abrasive wire saw, and the overall performance is better. From the comprehensive consideration of economic benefits and slicing effects, embodiment 2 is the best. The detection performance is shown in Example 2 in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com