A kind of multifunctional additive for oil-based drilling fluid and preparation method thereof

A technology of oil-based drilling fluid and multi-functional additives, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problem of not being able to protect the oil and gas layers during drilling and improving the cementing quality, few commercialized products, and ineffective effects. Satisfactory and other problems, to achieve good filter loss reduction effect, good filter loss reduction, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 80g of humic acid and 25g of cocoamide diethanolamine and place it in a 250mL flask, add 50mL of xylene and 3mL of concentrated sulfuric acid (6mol / L), install a water separator and a reflux condenser, and heat the flask with a 90°C water bath (toluene and The azeotrope boiling point of water is 85 ℃), when the amount of water in the water separator no longer increases, that is, when water is no longer generated, stop the reaction (the time is 3-5 hours), remove xylene, wash with 95% ethanol , The resulting product was dried in an oven at 50°C, and crushed into a black powdery solid to obtain a fluid loss reducer for oil-based drilling fluid.

Embodiment 2

[0033] Weigh 105g of humic acid and 15g of cocoamide diethanolamine and place it in a 250mL flask, add 35mL of xylene and 2mL of concentrated sulfuric acid (6mol / L), install a water separator and a reflux condenser, and heat the flask with a 90°C water bath (toluene and The azeotrope boiling point of water is 85 ℃), when the amount of water in the water separator no longer increases, that is, when water is no longer generated, stop the reaction (the time is 3-5 hours), remove xylene, wash with 95% ethanol , The resulting product was dried in an oven at 50°C, and crushed into a black powdery solid to obtain a fluid loss reducer for oil-based drilling fluid.

Embodiment 3

[0035] Weigh 90g of humic acid and 20g of cocoamide diethanolamine (placed in a 250mL flask, add 40mL of xylene and 3mL of concentrated sulfuric acid (6mol / L), install a water separator and a reflux condenser, and heat the flask with a 90°C water bath (toluene The boiling point of the azeotrope with water is 85°C), and when the amount of water in the water separator no longer increases, that is, when water is no longer generated, stop the reaction (the time is 3-5 hours); remove xylene, use 95% ethanol After washing, the obtained product is dried in an oven at 50°C; it is crushed into a black powdery solid to obtain a fluid loss reducer for oil-based drilling fluid.

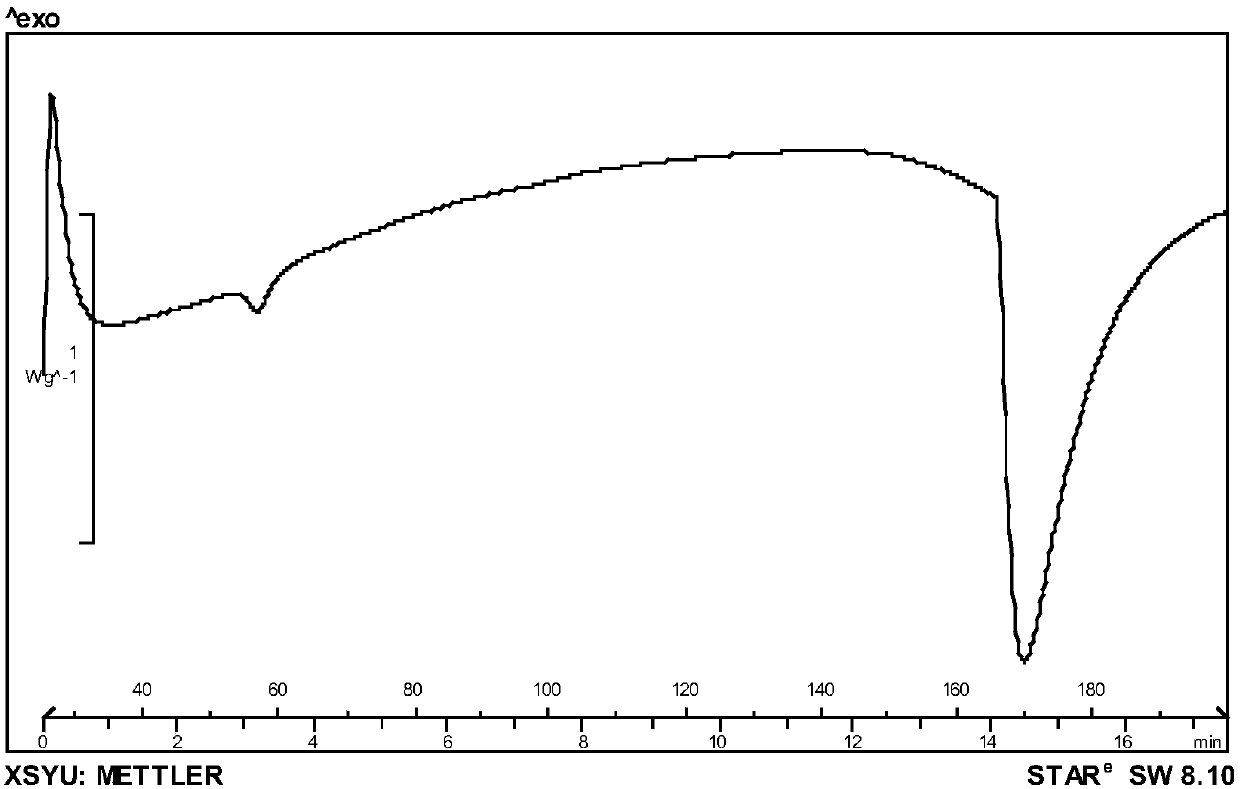

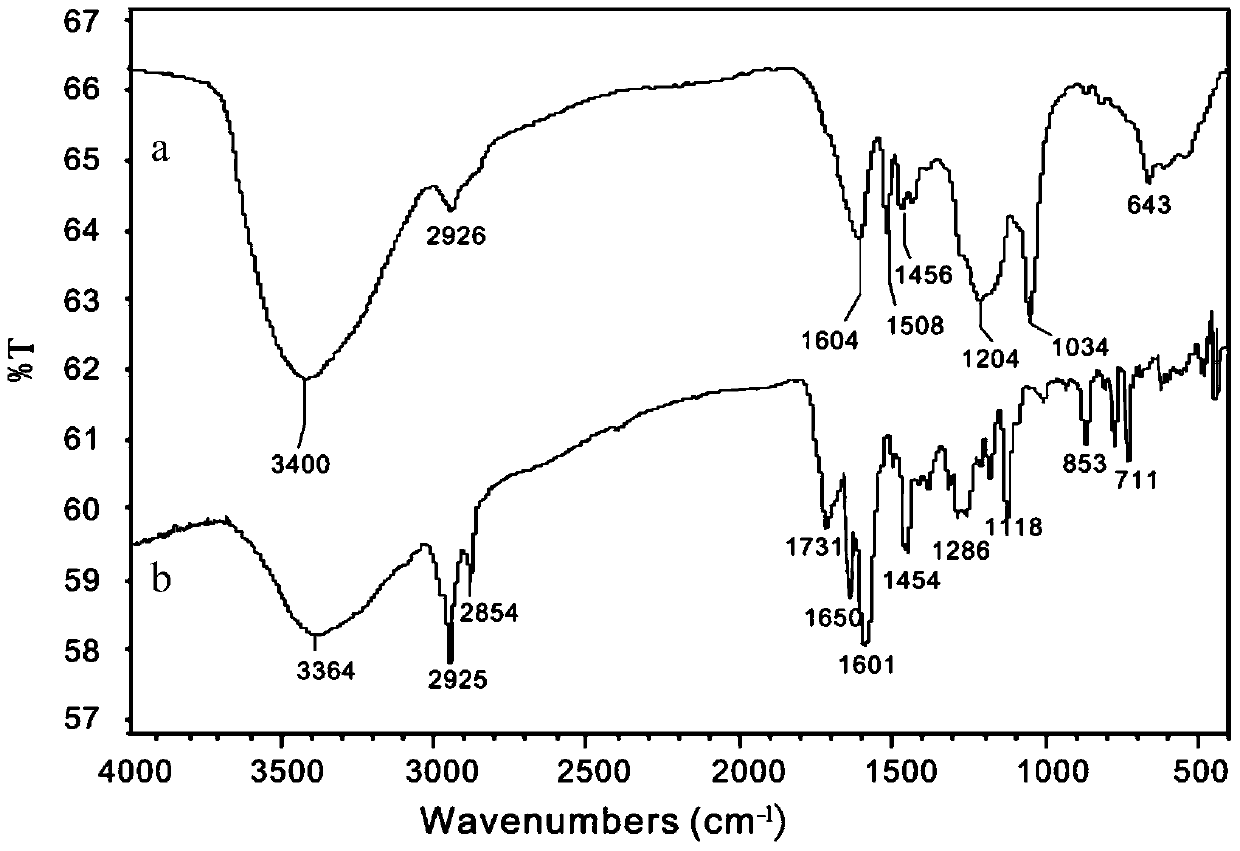

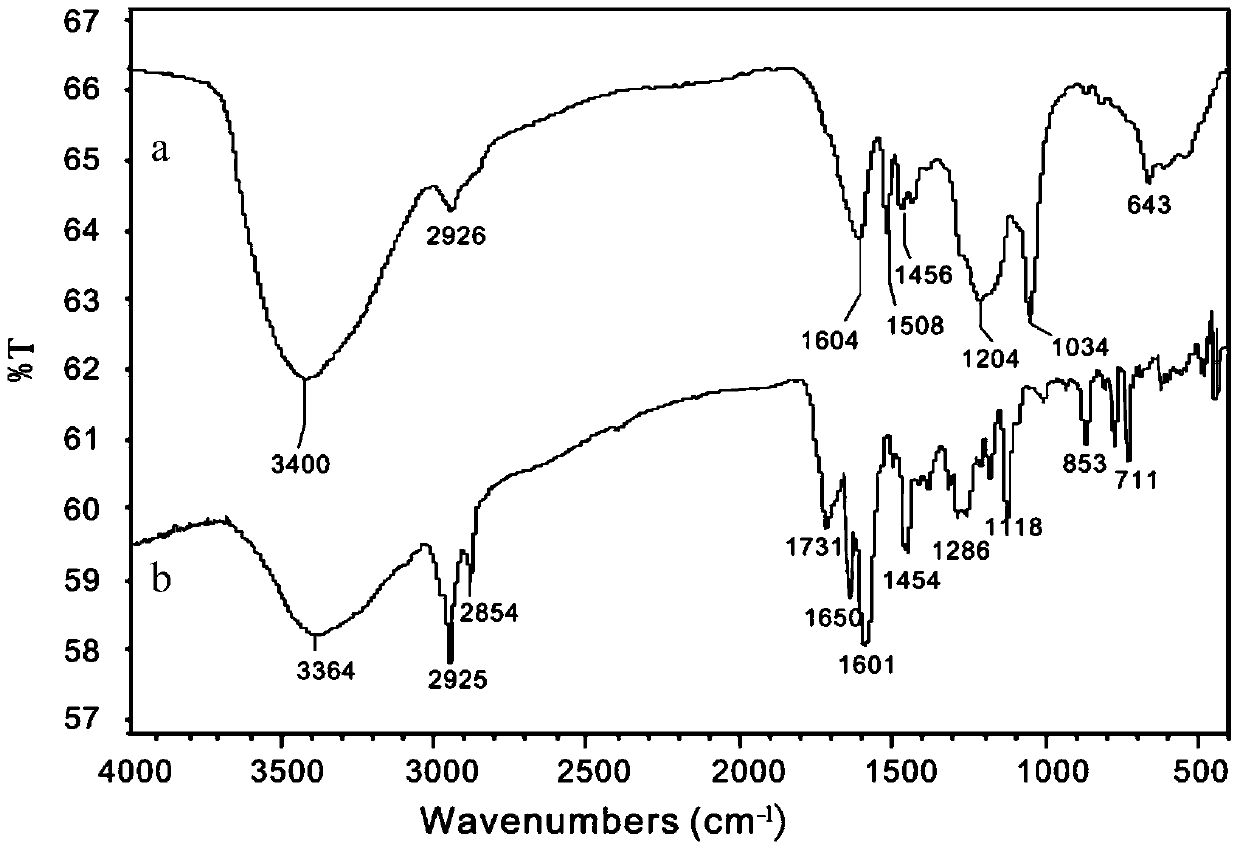

[0036] The structure of the final product obtained in embodiment 3 has been characterized by infrared spectroscopy, and the spectrogram is shown in figure 1 , the spectrum analysis is as follows:

[0037] figure 1 The frequency in b is 3364cm -1 It is the stretching vibration peak of phenolic hydroxyl group an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com