Water-based ink composition for writing instruments

A writing tool and water-based ink technology, applied in writing utensils, inks, applications, etc., can solve problems such as poor writing, unsatisfactory dry-out resistance, and increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

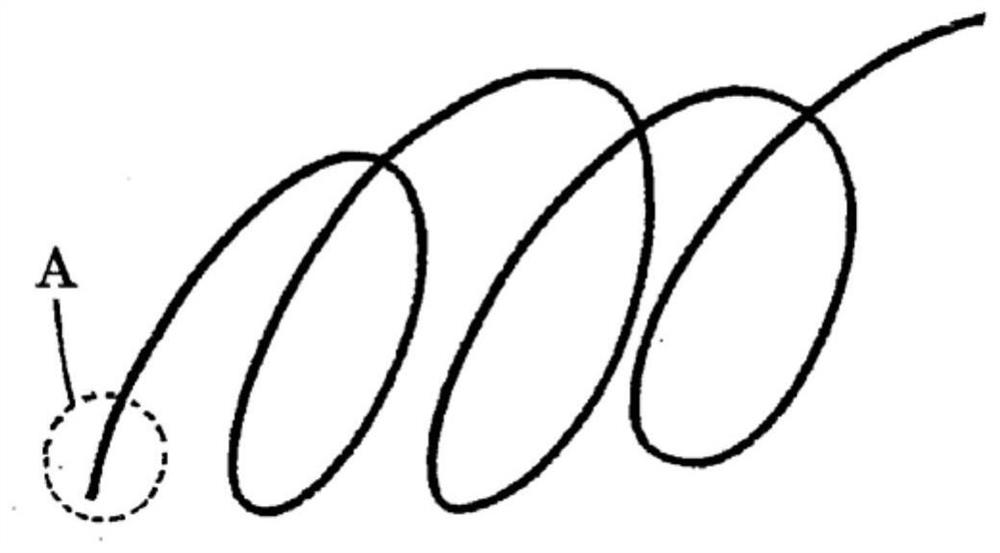

Image

Examples

Embodiment 1 to 9 and comparative example 1 to 5

[0067] Each aqueous ink composition for writing instruments was prepared according to the compounding composition shown in Table 1 below.

[0068] Thermochromic microcapsule pigments 1 and 2 as resin particles used as colorants in Examples 1 and 2 were obtained by Production Examples 1 and 2 below.

manufacture example 1

[0069] Production Example 1: Thermochromic Microcapsule Pigment 1

[0070] First, 1 part by mass of ETAC manufactured by Yamada Chemical Co., Ltd. as a leuco dye, 2 parts by mass of bisphenol A as a developer, and 24 parts by mass of myristate as a thermochromic temperature control agent Myristyl was heated and melted at 100° C. to obtain 27 parts by mass of a homogeneous composition. Hereinafter, "parts by mass" are simply referred to as "parts".

[0071] Then, 10 parts of isocyanate and 10 parts of polyol were added as a microcapsule filming agent to 27 parts of the homogeneous hot melt of the composition obtained above, and stirred and mixed. Next, the composition was emulsified at 25°C by using 60 parts of a 12% aqueous solution of polyvinyl alcohol as a protective colloid to prepare a dispersion liquid. Then, the dispersion liquid was treated by using 5 parts of 5% polyamine at 80° C. for 60 minutes, thereby obtaining microcapsules having a core-shell structure.

manufacture example 2

[0072] Production Example 2: Thermochromic Microcapsule Pigment 2

[0073] Similarly, 1 part of dye RED520 manufactured by Yamada Chemical Co., Ltd. as a leuco dye, 2 parts of 4,4'-(2-ethylhexylidene) bisphenol as a developer, and 24 parts 4,4'-(hexafluoroisopropylidene)bisphenol dimyristate as a thermochromic temperature control agent was heated and melted at 100° C. to obtain 27 parts of a homogeneous composition.

[0074] Then, 27 parts or more of the homogeneous hot melt of the composition obtained was gradually added to Gantlet AN by adding 40 parts of methyl vinyl ether·maleic anhydride copolymer resin manufactured by ISP Co., Ltd. as a protective colloid. -179 was dissolved in water in 100 parts of an aqueous solution at 90°C prepared while being neutralized with NaOH, and the mixture was dispersed in the form of oil droplets having a diameter of about 0.5 to 1.0 μm while heating and stirring. Then, 20 parts of melamine resin manufactured by Sumitomo Chemical Co., Lt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com