Light conversion module

A light conversion module and phosphor technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as increased viscosity of silica gel, uneven distribution of blue light, glare, etc., to improve light color uniformity, avoid damage to eyes, The effect of increasing the light angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Silicone rubber 10g (93.4%)

[0043] Organic Light Diffuser 0.2g(1.9%)

[0044] Aluminate yellow fluorescent material: 0.5g (4.7%)

[0045]The silicone rubber is a two-component addition type heat vulcanized liquid silicone rubber.

[0046] Add the liquid raw materials in the formula into the batching container, stir evenly, add the fluorescent material in the stirring state, stir evenly and carry out vacuum defoaming treatment. Add the liquid raw material mixture into the hemispherical mold and put it into an oven at 145°C for 20 minutes to cure. After curing, just take out the formed optical conversion module from the mold. The thickness of the prepared module is 1.0mm.

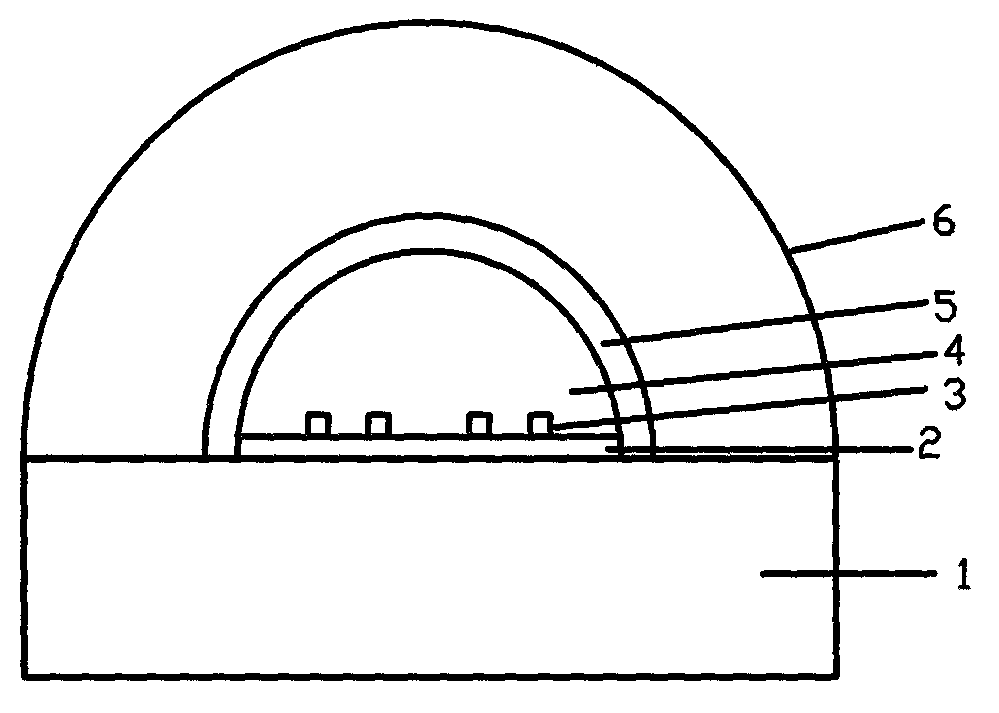

[0047] The prepared module is set on the base of the circuit board packaged with the LED chip, and is permanently fixed with an adhesive. The fluorescent material is excited by the light emitted by the blue LED to emit light, and recombines with the unabsorbed blue light to form white light with a...

Embodiment 2

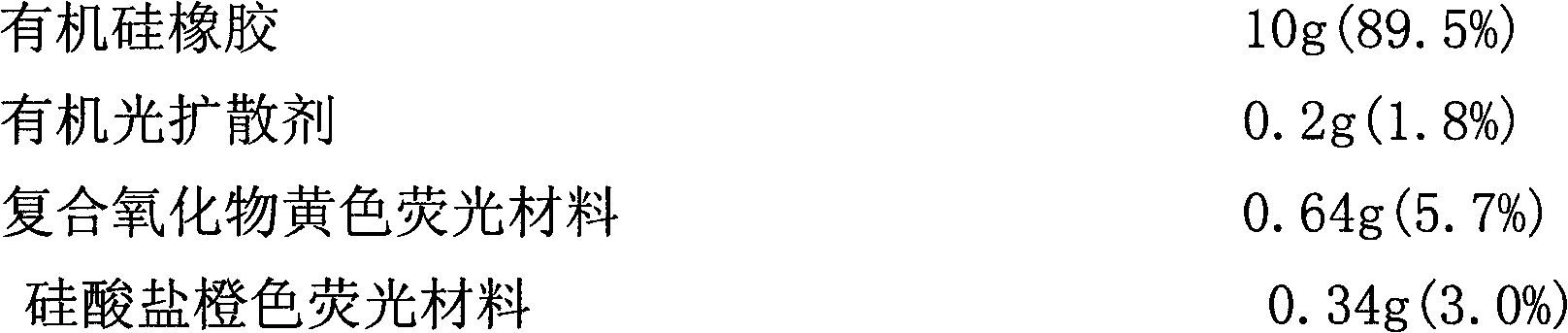

[0049]

[0050] The silicone rubber is a two-component addition type heat vulcanized liquid silicone rubber.

[0051] Add the liquid raw materials in the formula into the batching container, stir evenly, add the fluorescent material in the stirring state, stir evenly and carry out vacuum defoaming treatment. Add the liquid raw material mixture into the hemispherical mold, and put it into a 145°C oven for curing for 20 minutes. After curing, just take out the formed module from the mold. The thickness of the prepared module is 1.2mm.

[0052] The prepared module is set on the base of the circuit board packaged with the LED chip, and is permanently fixed with an adhesive. The phosphor powder is excited by the light emitted by the blue LED to emit light, and combines with the unabsorbed blue light to form warm white light with a color temperature of 2700K and a light output angle of 175 degrees.

Embodiment 3

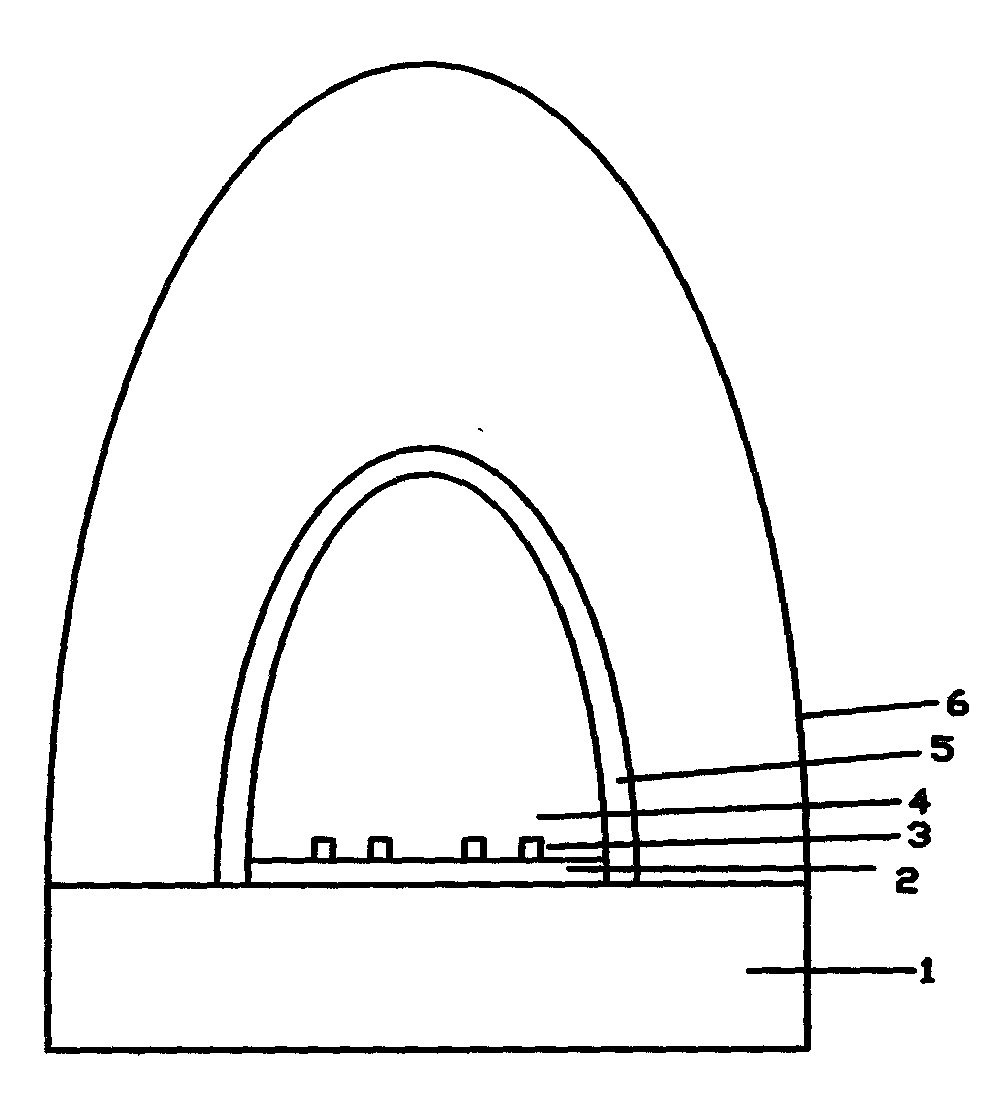

[0054] Example 2 is basically the same as Example 3, except that the light conversion module prepared in Example 3 is candle-shaped, and the light emitting angle of the lamp prepared by using it is 230 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com